Telescopic support leg for work tables

A telescopic and supporting leg technology, applied in metal processing and other directions, can solve the problems of inability to adjust the height, inconvenient use and storage, and inconvenient use next time, so as to achieve the effect of convenient and fast use and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

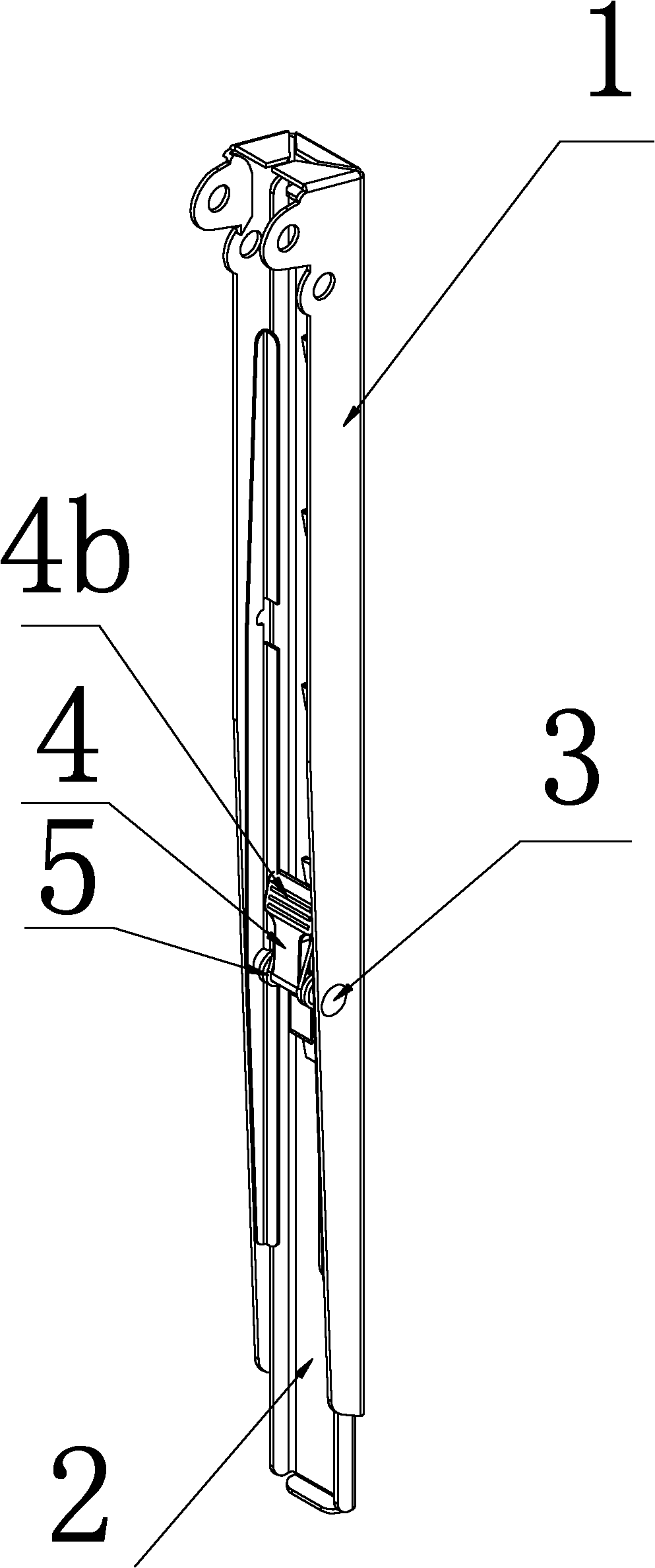

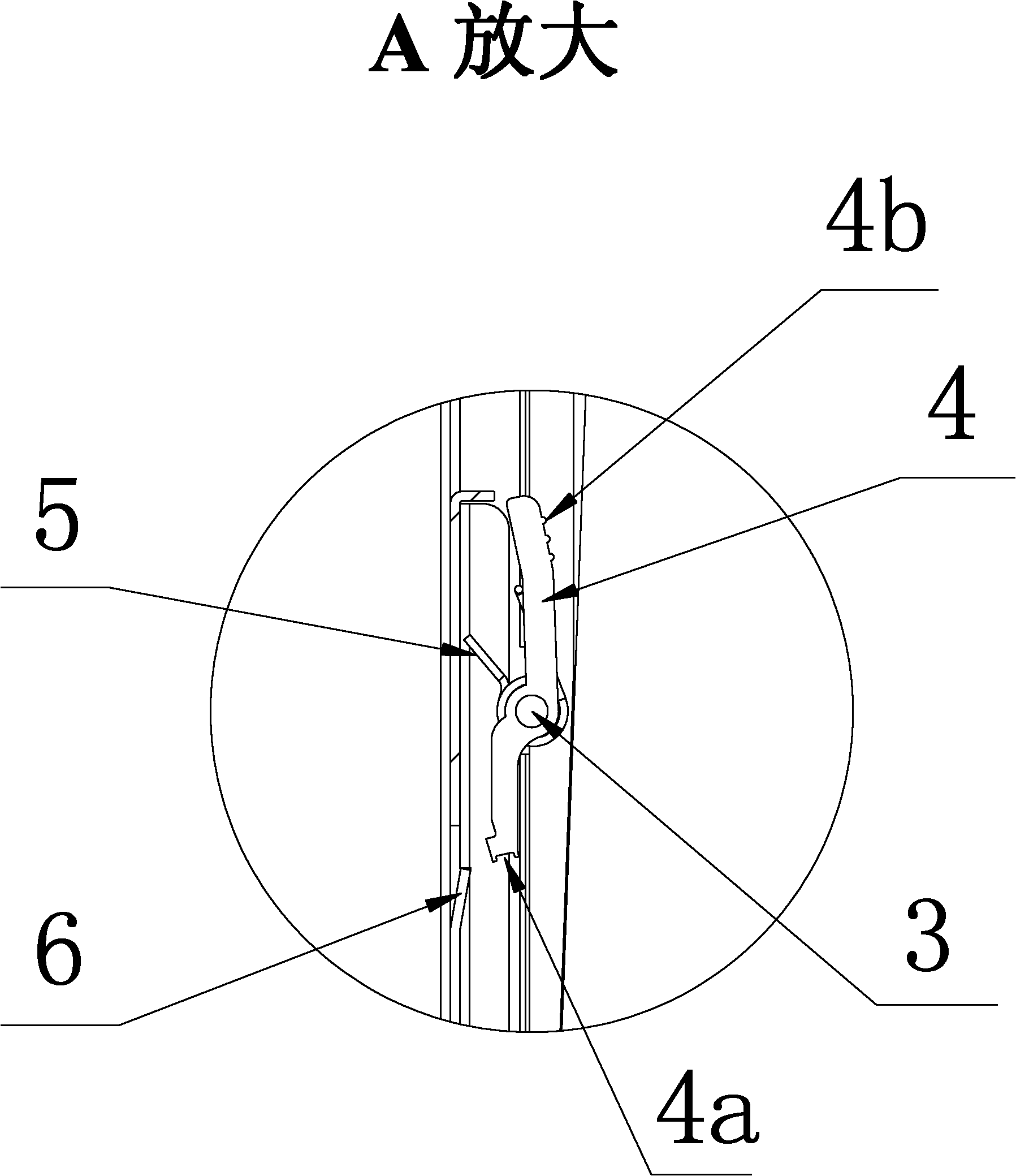

[0021] Example: Combine figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the telescopic support legs of the workbench provided by the present invention include a main leg 1 and an extension leg 2. As in the conventional technology, the main leg 1 is provided with a chute (not shown in the figure), and the extension leg 2 There are guide rails matching the chute (not shown in the figure). And the technical improvement of the present invention is: it is equipped with elastic positioning switch on main leg 1, and this elastic positioning switch is installed on the main leg 1 by pivot 3 and can rotate around pivot 3 seesaw 4, and is assembled on The torsion spring 5 on the pivot 3 constitutes; at the same time, this embodiment is equipped with five stoppers that cooperate with the elastic positioning switch at equal intervals on the extension leg 2 to prevent the extension leg 2 from being drawn in. In this embodiment, the stopper is specifically Be the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com