Measuring device for exhaust area of engine turbine guider throat

A turbine guide and measuring device technology, applied in the direction of mechanical area measurement, etc., can solve the problems of cumbersome operation, inability to meet production development, low measurement efficiency, etc., and achieve the effect of simplifying measurement operation, eliminating manual calculation, and improving measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

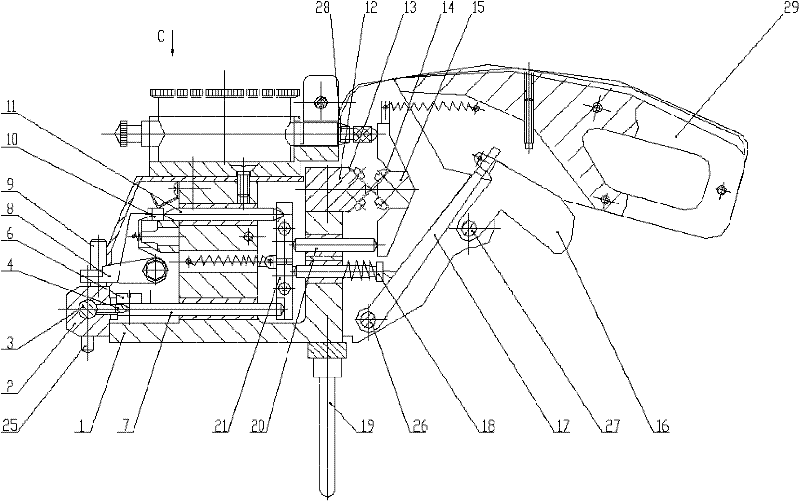

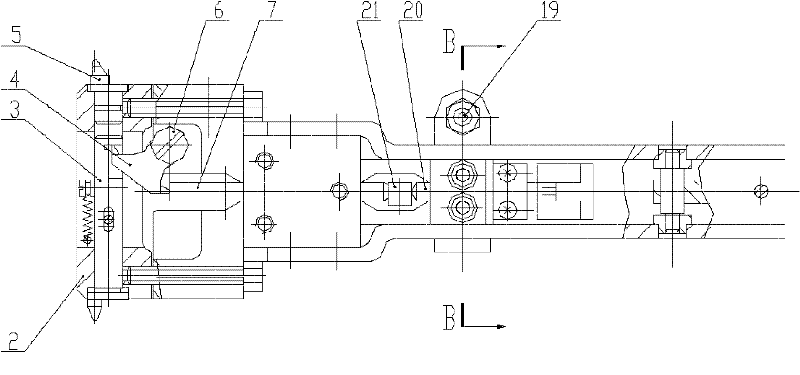

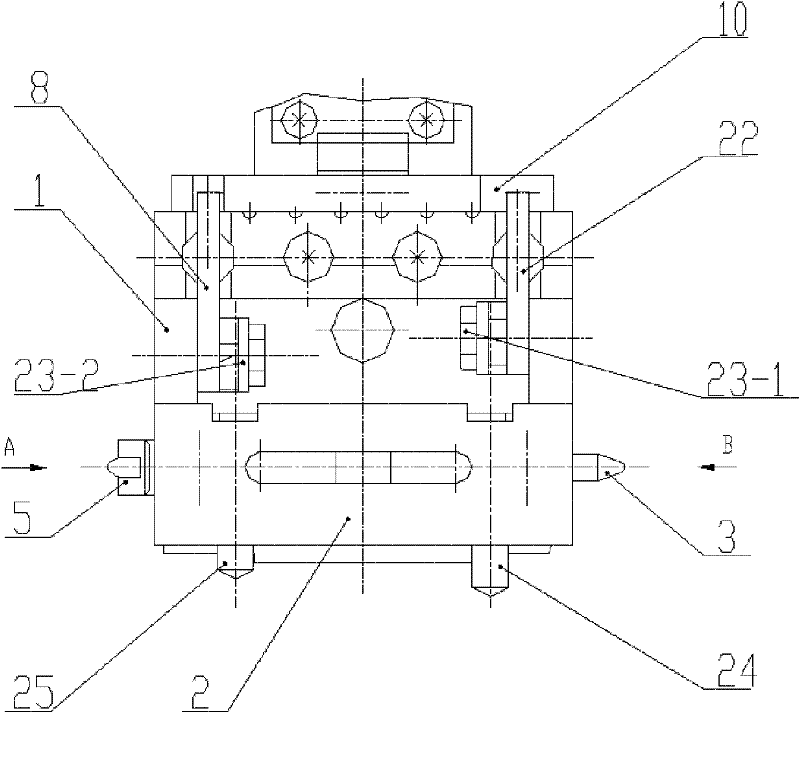

[0031] The structure and working principle of the engine turbine guider throat exhaust area measuring device of the present invention will be further described below with reference to the accompanying drawings.

[0032] In this embodiment, the structure of the engine turbine guider throat exhaust area measuring device is as follows: figure 1 , figure 2 , image 3 As shown, it consists of a housing, a supporting positioning mechanism, a measuring mechanism, a transmission mechanism and an auxiliary mechanism. From the perspective of convenient installation, the shell is composed of the first shell 1 and the second shell 2 . The support positioning mechanism is made up of two positioning rods 9 and a support rod 19, and the two positioning rods are installed on the second housing 2 at a distance (see Figure 7 ), the support rod is installed on the first housing 1 (see figure 1 , figure 2 , Figure 4 ), the line connecting the installation positions of two positioning ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com