Azimuth angle adjustable mounting ring of square ceiling lamp

A technology of angle adjustment and installation ring, which is applied in the direction of lighting devices, lighting auxiliary devices, lighting device components, etc., can solve the problems of deviation in drilling, inconvenient installation orientation, and difficult installation orientation of square ceiling lamps, etc., to achieve time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

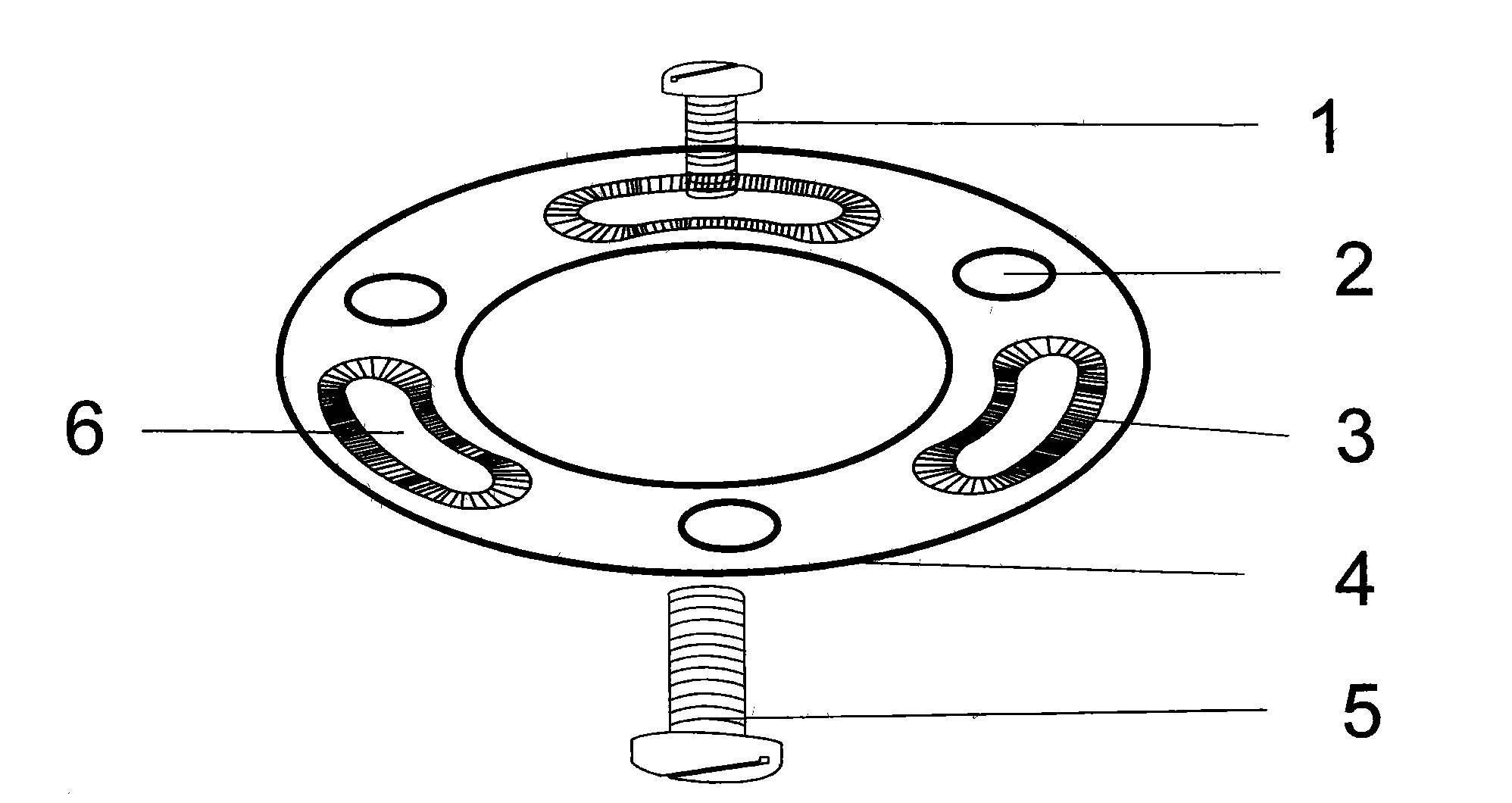

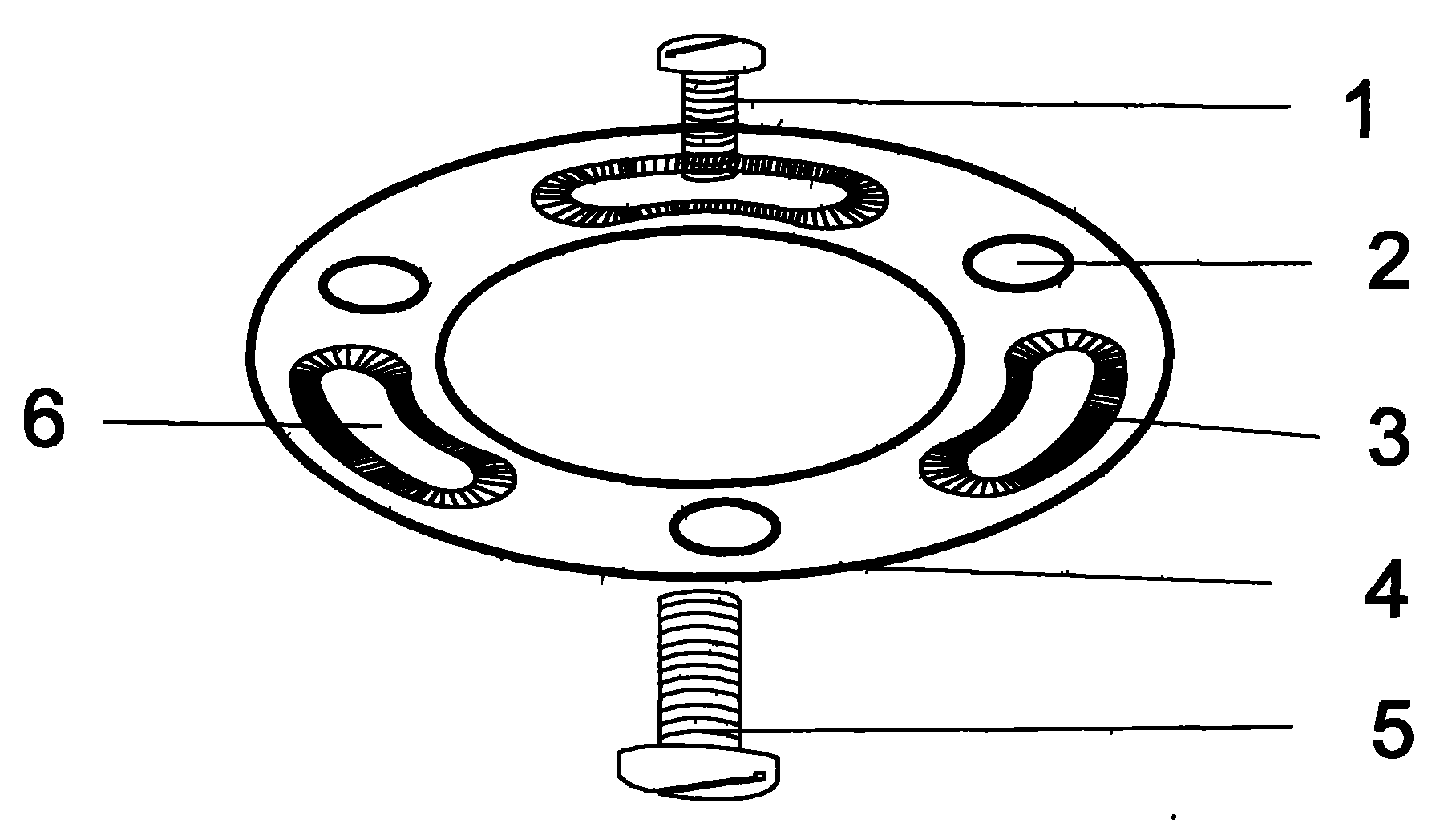

[0010] exist figure 1 Among them, there are three to five screw holes (2) and three to five arc-shaped grooves (3) on a piece of ring-shaped metal or plastic, and there are arc-shaped screw holes (6) in the middle of the arc-shaped grooves, and the arc-shaped screw holes can Go through the bolt of the screw (1), but not the nut of the screw. Put the preparatory screw (1) in the arc-shaped screw hole (6) of the installation ring (4), put the grooved side of the installation ring facing the ceiling, and fix it to the ceiling with the screw (5) through the screw hole (2) After fixing, the preparatory screw (1) can move left and right in the arc groove (3).

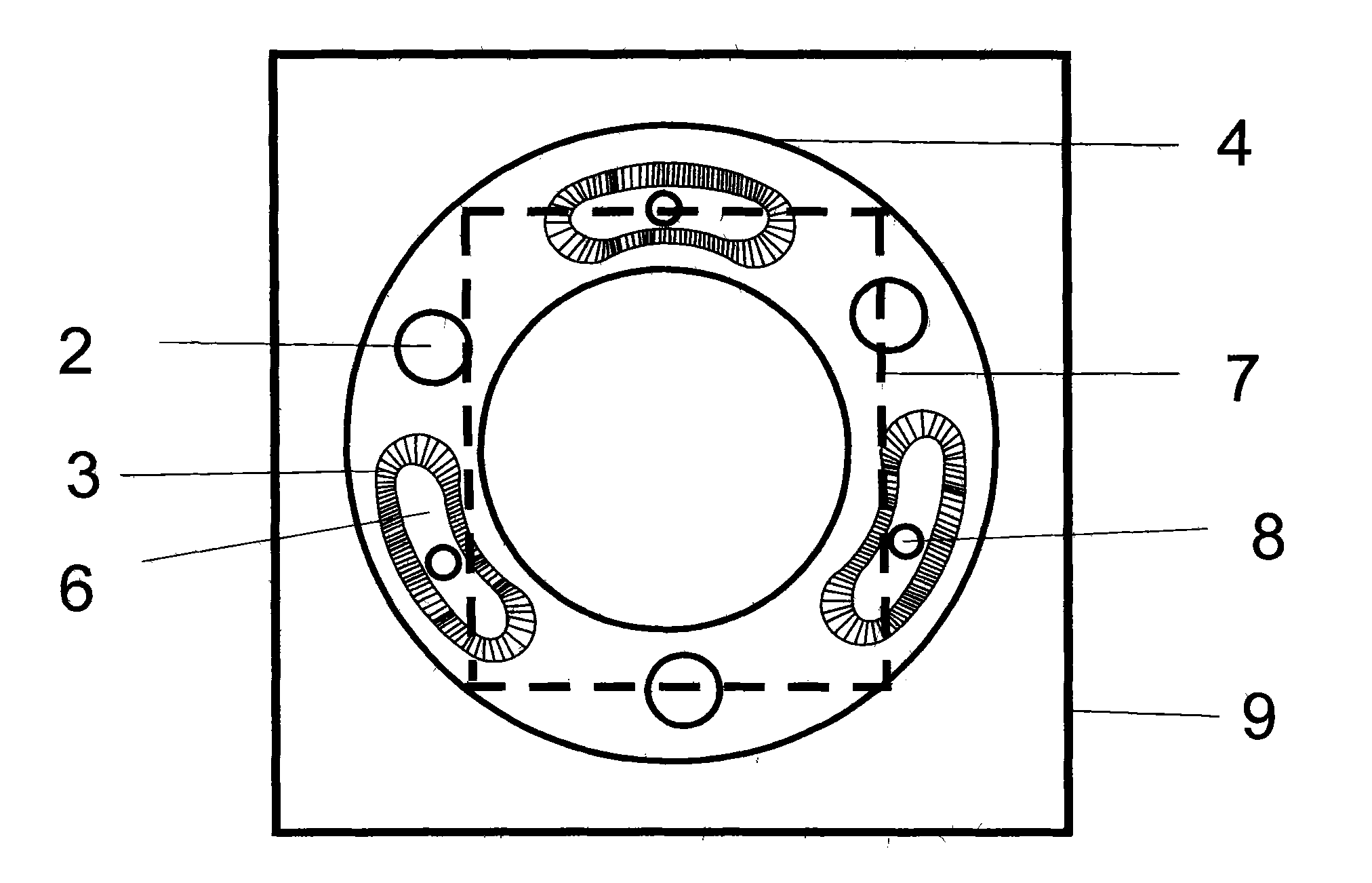

[0011] exist figure 2 In the shown embodiment, there is a square marking line (7) on the protruding side of the installation ring (4). The position is fixed on the ceiling. Then align the ceiling lamp screw hole (8) on the ceiling lamp shell (9) with the preparatory screw (1) on the installation ring, add the washer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com