Labyrinth type regulating valve pressure reducing device

A technology of pressure reducing device and regulating valve, applied in valve device, valve device for absorbing fluid energy, valve details, etc., can solve the problems of low pressure reducing efficiency, complicated processing of pressure reducing device, expensive production cost, etc. The effect of steam turbid noise, convenient processing and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment, the specific embodiment of the utility model is described in further detail. The following examples are used to illustrate the utility model, but not to limit the scope of the utility model.

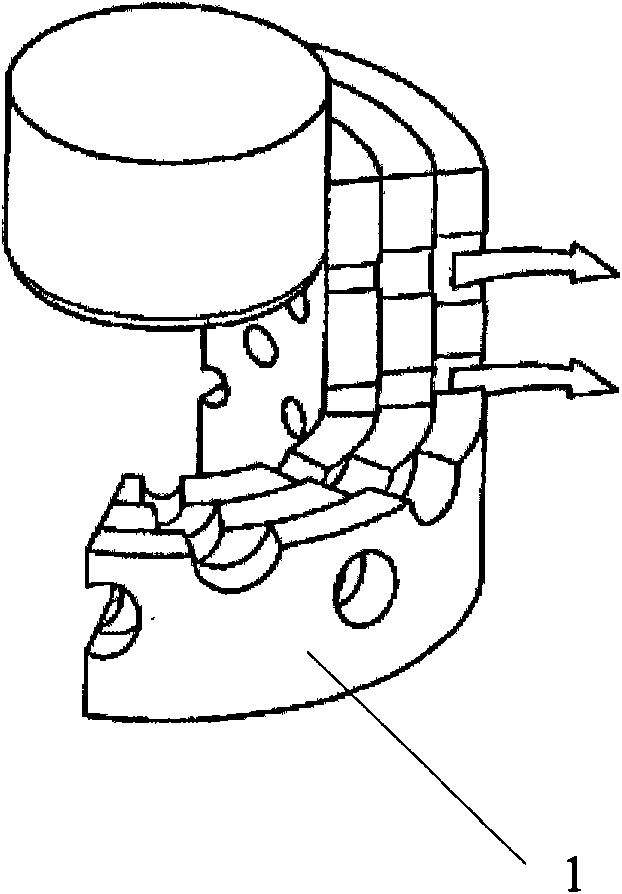

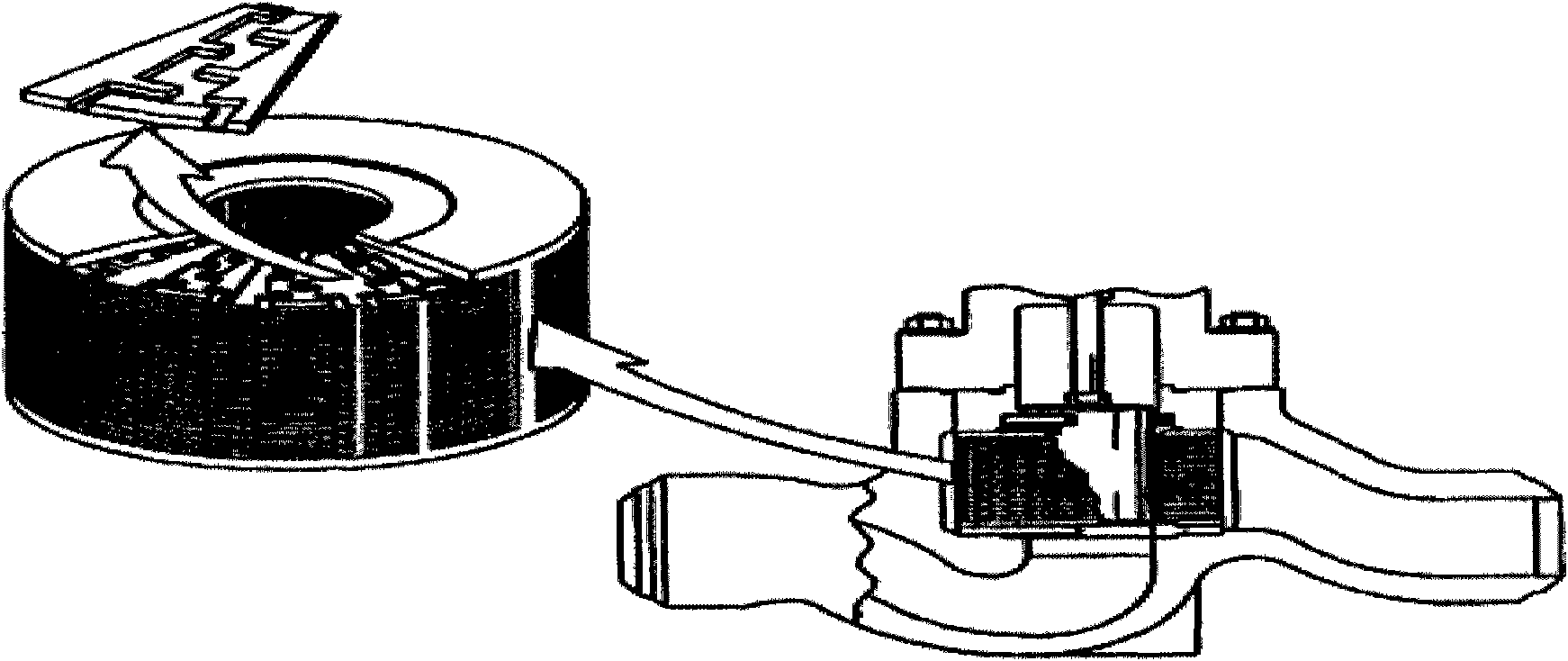

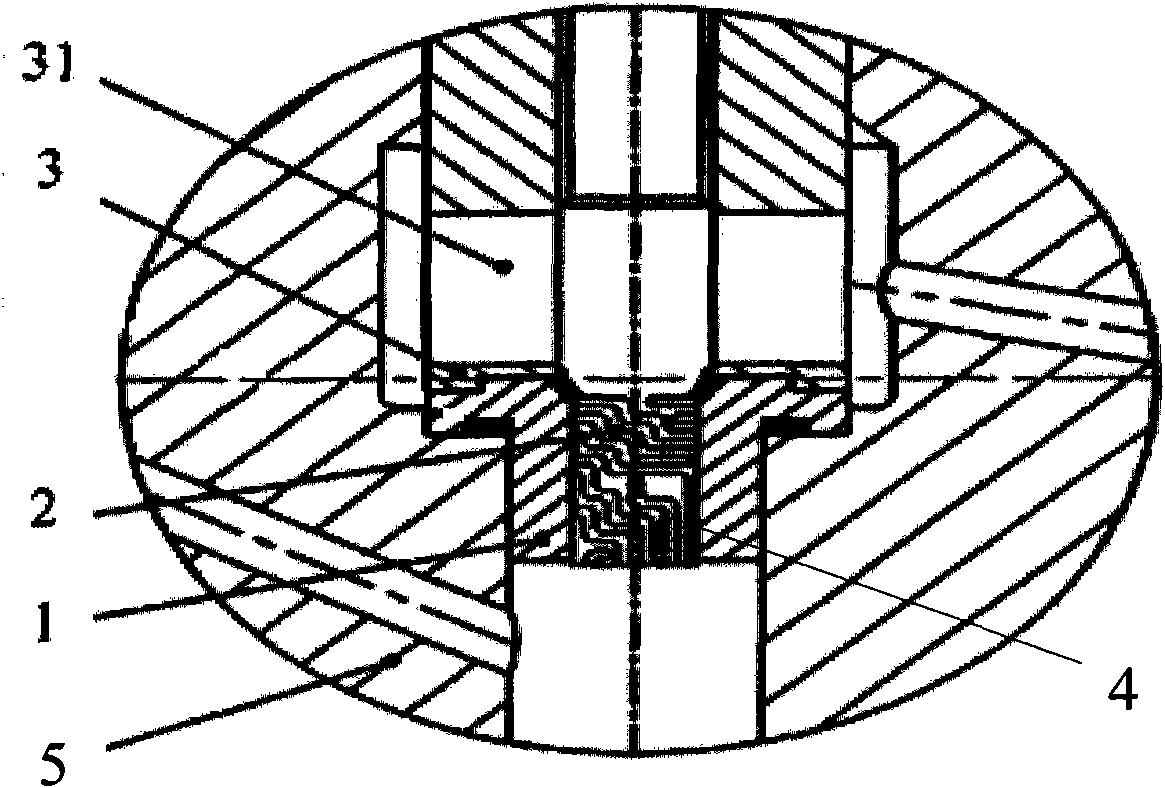

[0031] refer to Figure 3-Figure 5 , The labyrinth regulating valve pressure reducing device of the embodiment of the utility model includes a valve seat 1, a valve core 2 and a sleeve 3, the valve core 2 is located inside the valve seat 1, and the annulus of the valve core 2 has several grooves 4 in the axial direction. , the groove 4 has at least one curved portion, and the curved portion is rounded. The sleeve 3 is sleeved on the periphery of the valve core 2 , and the sleeve 3 has a window 31 whose height is equal to or greater than the length of the groove 4 . The groove 4 has an inlet and an outlet, the direction of the bending portion is not limited in the groove 4 , and the outlets of the groove all face the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com