Full spiral lamp tube cutter and full spiral lamp tube cutting process

A tube cutting machine and spiral technology, which is applied in the field of full spiral lamp tube cutting machine, can solve the problems of low work efficiency, inability to meet cutting requirements, cutting off full spiral lamp tube pins, etc., and achieve the effect of precise cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

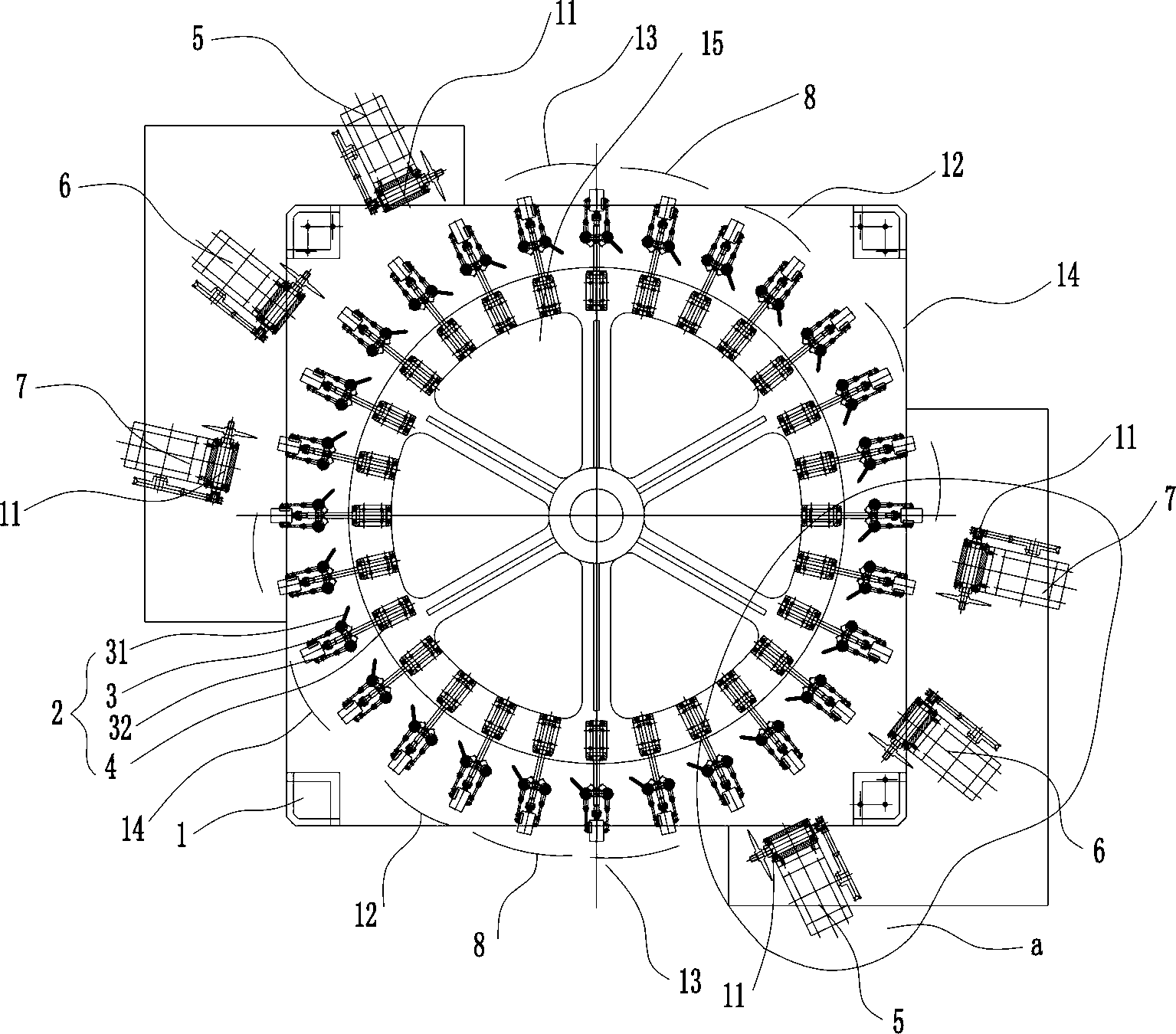

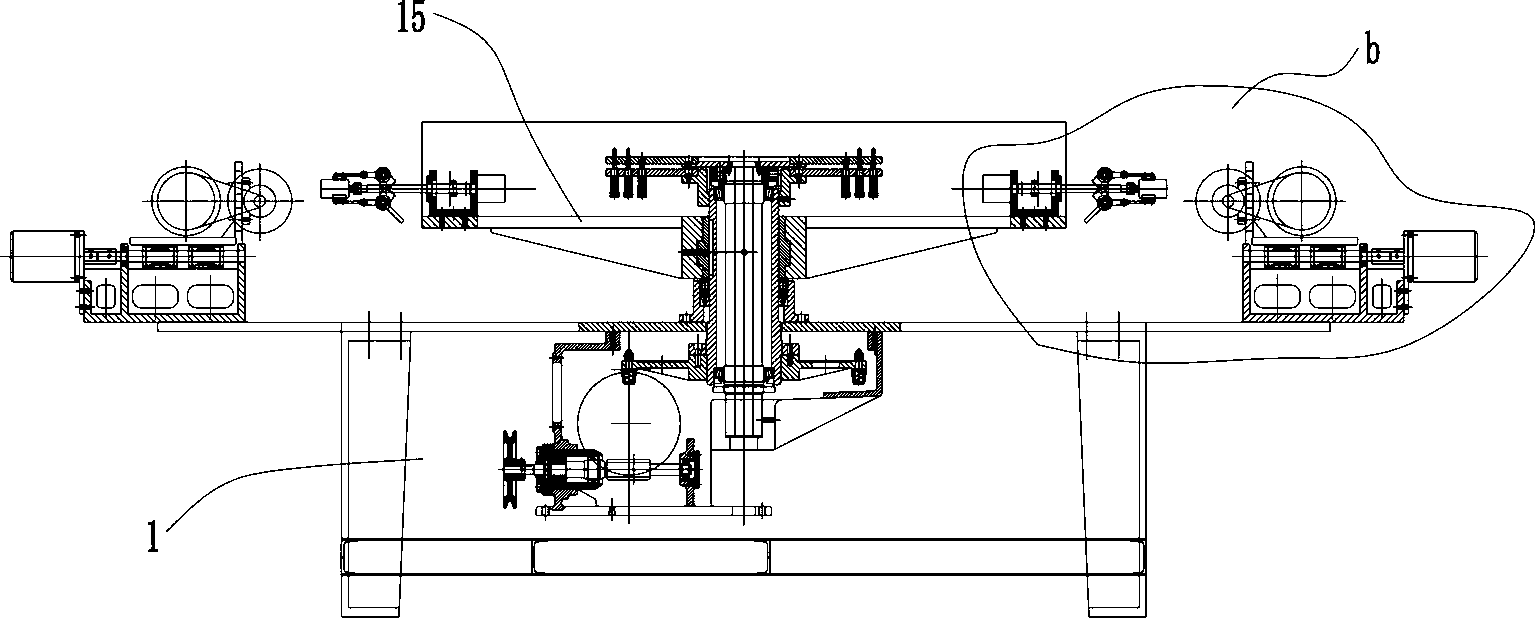

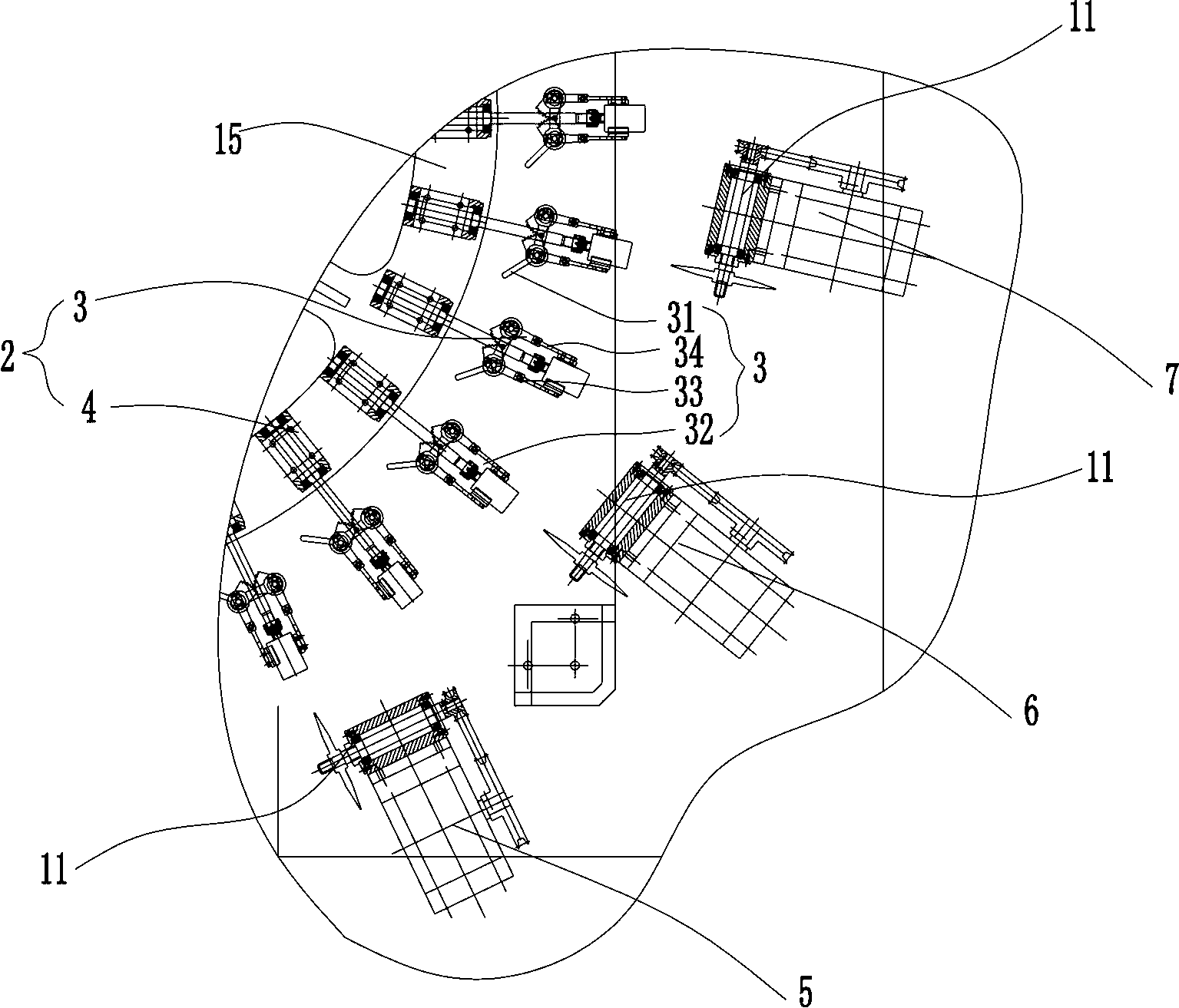

[0031] see Figure 1-5 , this implementation case includes: a multi-station body 1, the body 1 is provided with a number of station heads 2 that run intermittently on the stations, and the station head 2 is provided with a fixture 3 and a fixture 3 for fixing the full spiral lamp tube 9 The steering device 4 and the control device for controlling the steering angle of the steering device 4, coordinating the steering angle of the steering device 4, and the intermittent movement of the station head. On the bit head 2, the steering device 4 of the clamp 3 is a stepper motor 41 connected to the clamp 3 or an angle actuator or a mechanical device such as a gear and a shift fork that cooperate with each other. In this embodiment, it is a stepper motor; wherein the steering device 4 It is provided with an angler that feeds back the steering angle of the fixture 4 to the PLC control device. The steering device, angle detector, and PLC control device form a closed loop, which has achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com