Box foaming rocking mechanism

A technology of swing mechanism and link mechanism, which is applied in the field of box foam swing mechanism, can solve problems such as long debugging time, swing core-pulling block with gallbladder, and increased load of foaming equipment, so as to reduce material and processing costs and improve mechanism Lightweight and flexible, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

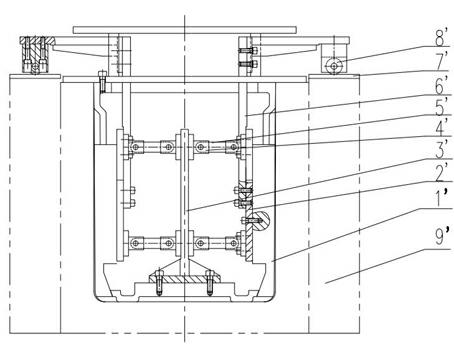

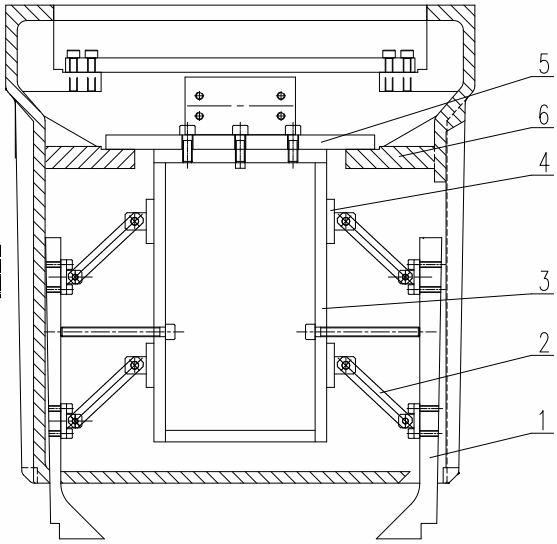

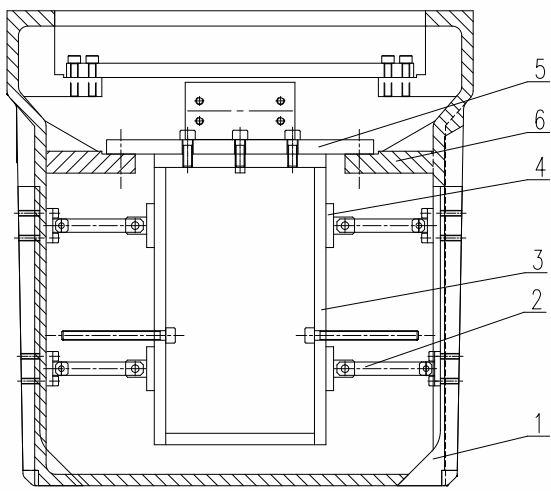

[0018] Such as figure 2 , image 3 As shown, the box foaming oscillating mechanism of the present invention includes a oscillating core pulling block 1, a connecting rod mechanism and a fixing frame 3 for fixing the connecting rod mechanism. The connecting rod mechanism includes a connecting rod 2 and a connecting rod seat 4, and the connecting rod One end of the connecting rod seat is movably connected with the connecting rod seat through a pin shaft, and the connecting rod seat is fixed on the fixed frame. The rod can move in a vertical plane; the fixed frame is a rectangular frame structure, and its upper end surface is fixed on the connecting plate 5 of the fixed frame, and the connecting plate of the fixed frame is fixed on the core body 6; the connecting rod is movably connected to the end faces of both sides of the rectangular holder.

[0019] The working principle of the box foaming swing mechanism of the present invention: when the foamed pre-packed box is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com