Full-automatic size edge sealing production line and production method

A fully automatic, production line technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of easy gelling, low precision, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

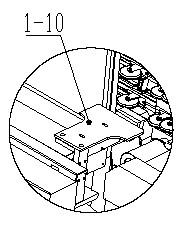

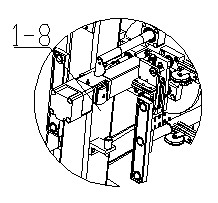

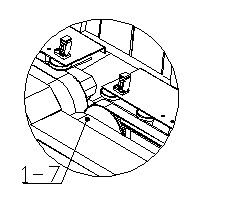

[0020] Embodiment 1: with reference to attached Figure 1-9 . A fully automatic rubber material edge banding production line, which includes a transition section 1-1, a film feeding table 1-2, a glue output part 1-3, an edge banding table 1-4, a film output table 1-5, and a transmission device 1- 7. Gluing head 1-8, insulating glass 1-9, glue mixing device 1-11, console 1-12; the glass delivery device 1-6 is provided in the film output table 1-5; the transmission device 1-7 is an opening transmission mechanism, and a photoelectric thickness measuring device 1-10 is provided in the transition section 1-1 or the film loading station 1-2; in the opening transmission mechanism, two synchronous belt transmission mechanisms 1 and 2 are arranged in parallel, One of them is the adjustable synchronous belt transmission mechanism 1, the other is the fixed synchronous belt transmission mechanism 2, and the adjustable synchronous belt transmission mechanism 1 automatically adjusts the di...

Embodiment 2

[0027]Embodiment 2: On the basis of embodiment 1, the production method of a fully automatic rubber edge banding production line, it includes a photoelectric data processor, when the hollow glass enters the entrance end of the film-feeding platform 1-2 from the transition section 1-1, The photoelectric thickness measuring sensor located at the lower part of the entrance of the film loading table 1-2 receives the thickness measuring instruction, and instructs the cylinder to power on to drive the photoelectric thickness measuring sensor to quickly perform photoelectric detection on the convex and concave points of the thickness of the insulating glass, and the photoelectric detection results are obtained. After the data is processed by the photoelectric data processor, the thickness parameter of the insulating glass can be obtained, and then the servo motor 301 in the spacing adjustment mechanism 3 of the instruction opening transmission mechanism receives the command to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com