Insecticidal polymer matrix comprising hdpe and ldpe

An insecticidal and polymer technology, applied in the direction of insecticides, biocides, animal repellents, etc., can solve the problems of not indicating the content of PBO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

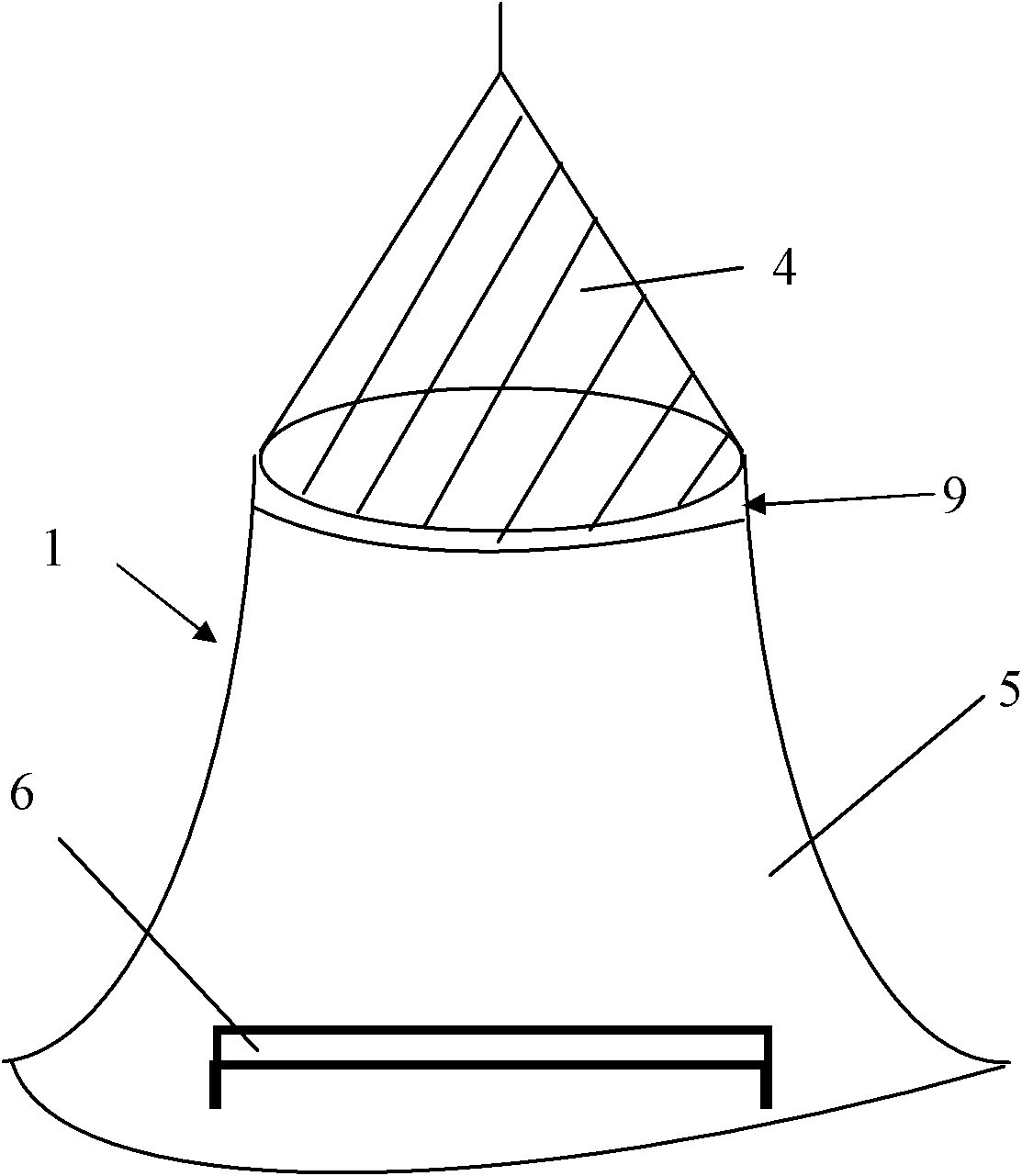

Image

Examples

Embodiment Construction

[0059] In terms of solution, the path to the present invention does involve several intermediate steps, simple but not straightforward.

[0060] In teachings in the field of insecticidal nets, it has currently been assumed that PBO must be pre-delivered to mosquitoes well before exposure to DM, as it is believed that PBO needs to be in the mosquito for a period of time before temporarily disrupting the resistance mechanisms. The aforementioned International Patent Application WO 2006 / 11155 reflects this. Because PBO is degraded by sunlight / visible light to generate free radicals that cause DM degradation, it is currently believed that providing PBO and DM on the net surface at the same time and at the same location is an obstacle to effective insecticidal nets, because mosquitoes must be exposed to DM before DM exposure. The time lapse between exposures to PBO simultaneously resulted in DM degradation. The conclusion implied at this point is that polymers doped with DM and PB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com