Combing device for combing fibrous material

A fiber material and combing technology, which is applied in the direction of combing machines, fiber processing, textiles and papermaking, etc., can solve the problems of increased noise, high vibration of loading device, and limitation of pressure load adjustability, etc., to reduce noise level and vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

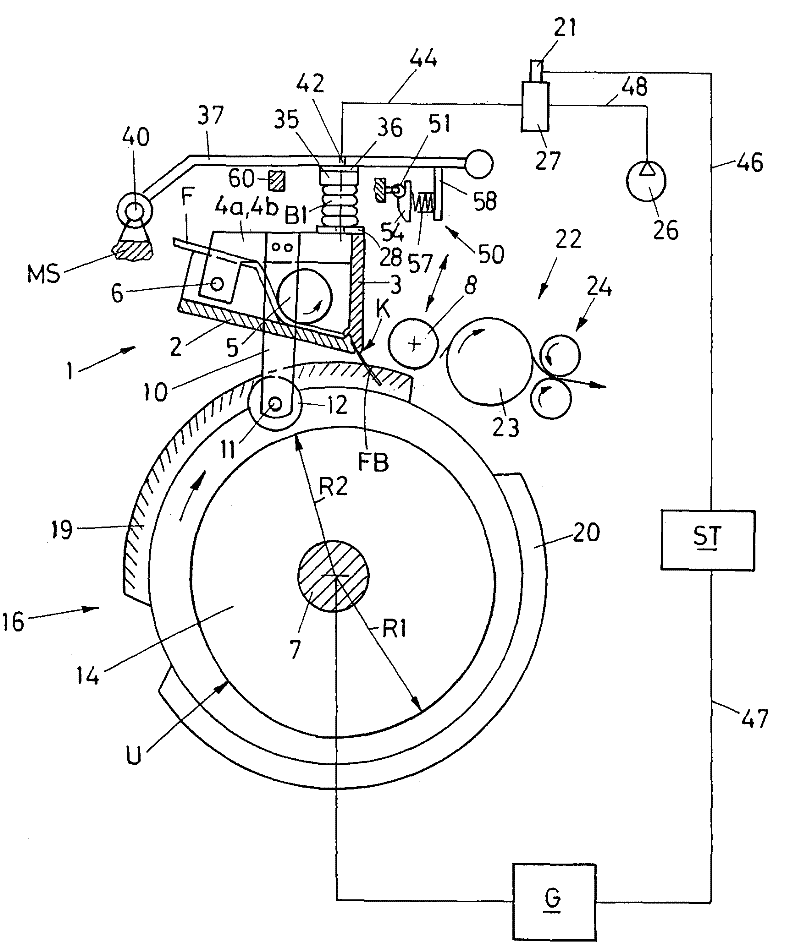

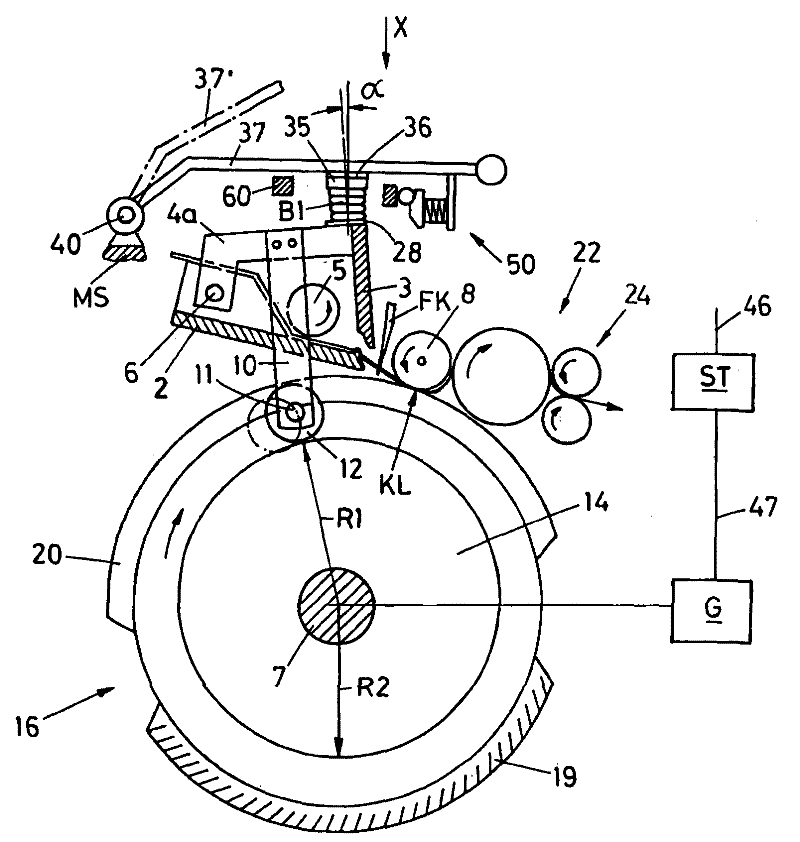

[0030] exist figure 1 A schematic diagram of a combing head of a combing machine is shown in . Usually a large number (for example eight) of such combing heads are arranged next to each other and are drive-connected to one another via continuous drive elements (longitudinal shafts). However, it is also possible to equip the combing heads each with a single drive.

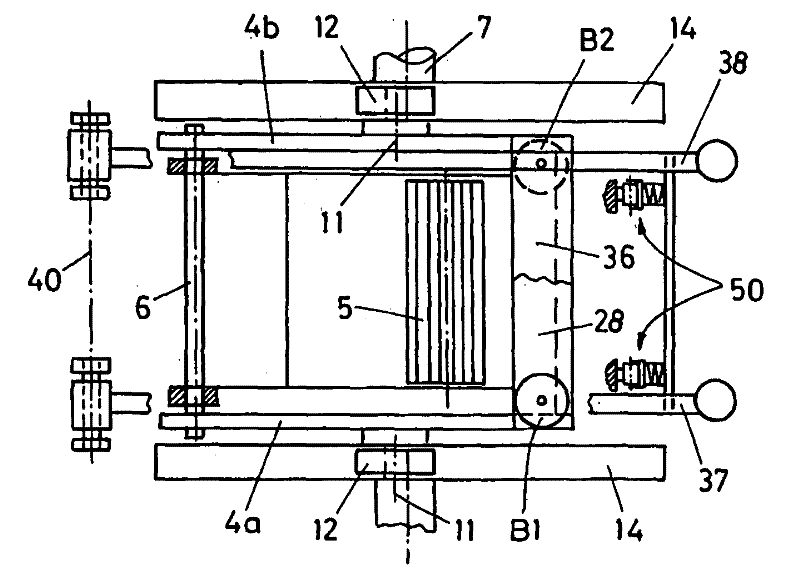

[0031] A nipper unit 1 (referred to as nipper 1 ) is arranged above the combing cylinder 16 connected to the driven shaft 7 , and the nipper unit is provided with a lower nipper 2 and an upper nipper 3 . The upper nipper 3 is connected to the lateral arms 4a, 4b (see also image 3 ), the arm is swingably supported on the lower nipper around the swing axis 6 . Since the lower nipper 2 assumes a stationary position in the present exemplary embodiment (that is, it cannot move during the combing cycle), the pivot axis 6 can also be accommodated directly in the frame MS. On the arms 4a, 4b are each fastened a clip 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com