Chassis structure of a motor vehicle body

An automobile body and automobile technology, which is applied in the direction of load-bearing body structure, substructure, superstructure, etc., can solve the problems of high production consumption and production cost, and achieve the effect of increasing torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

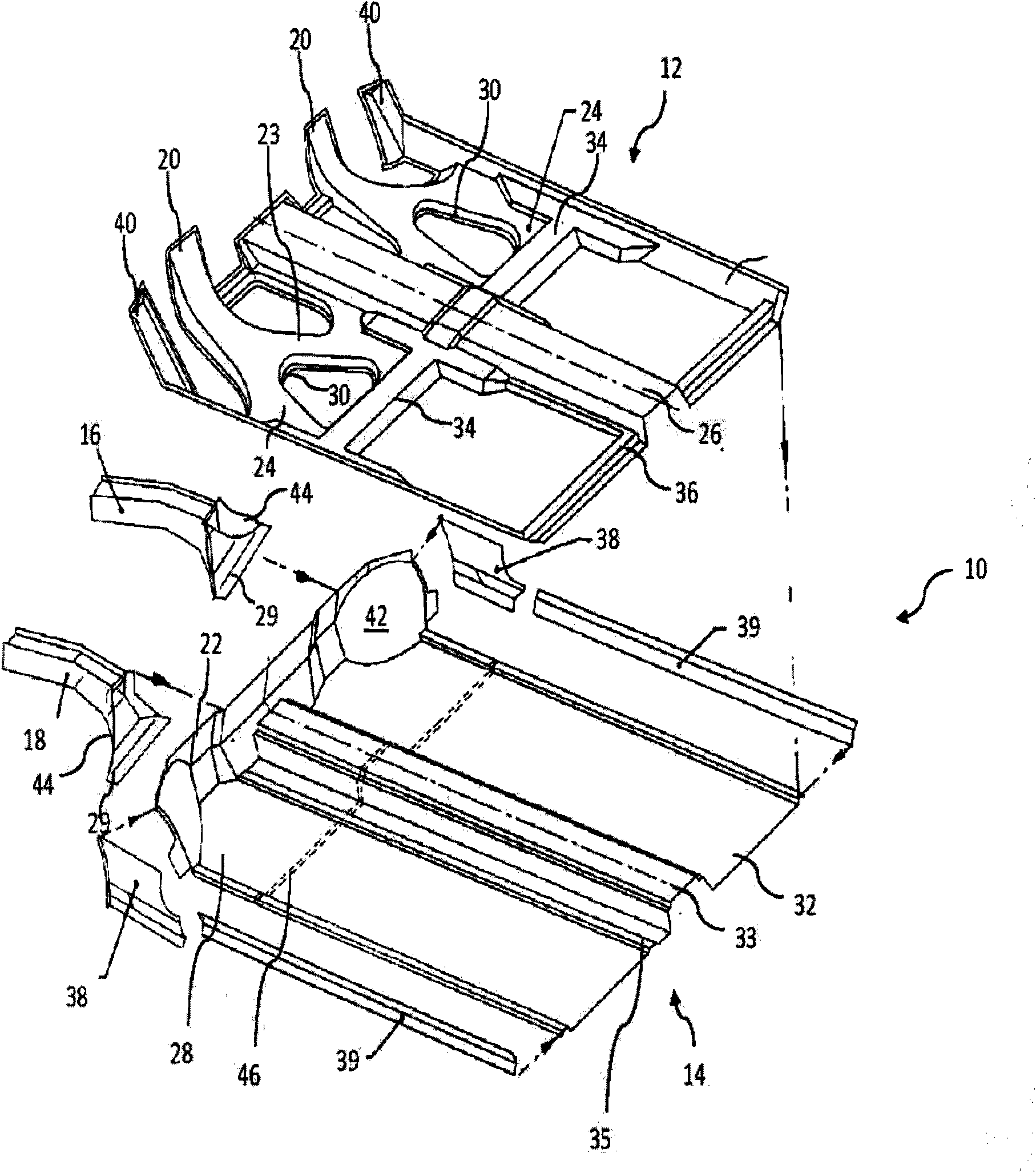

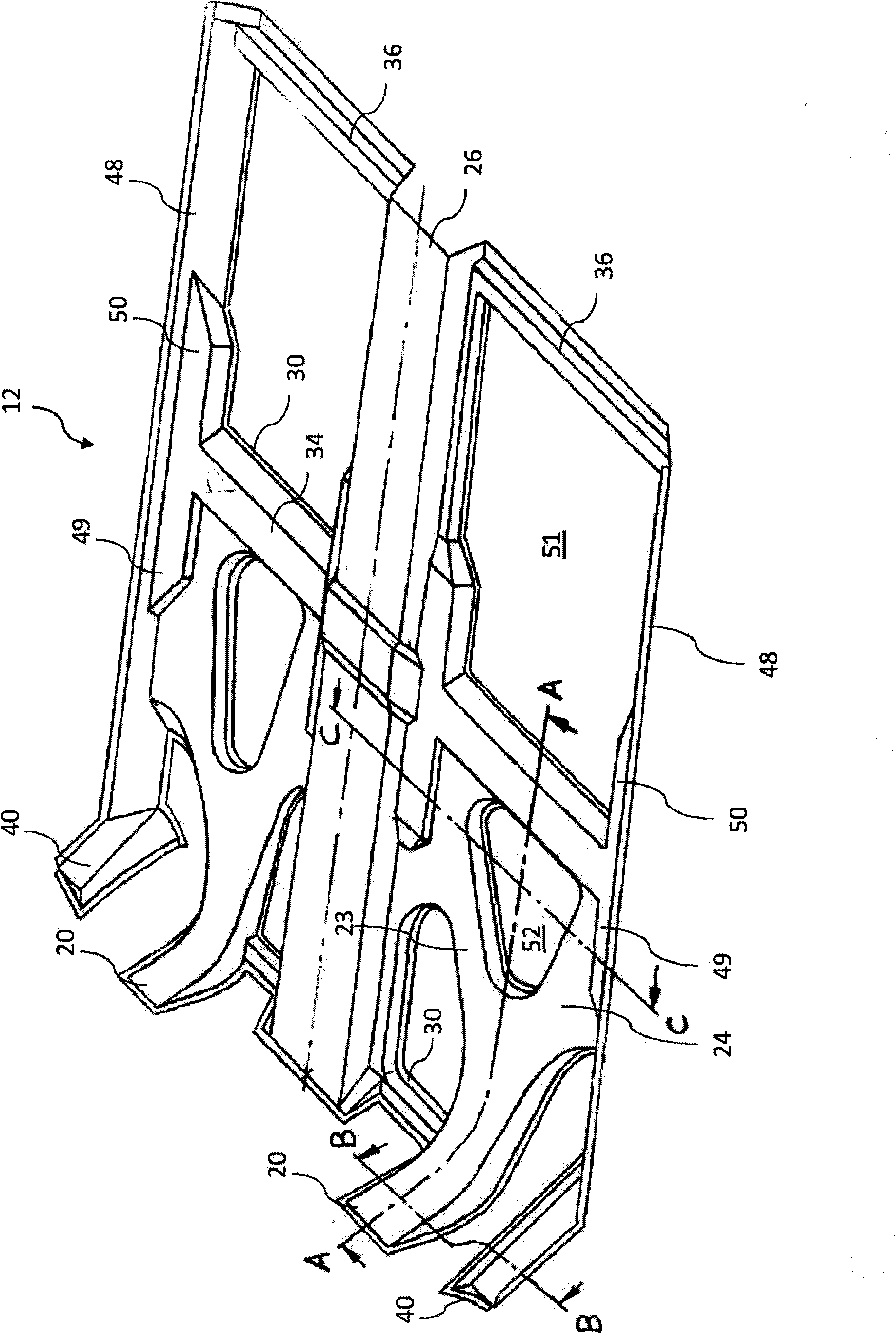

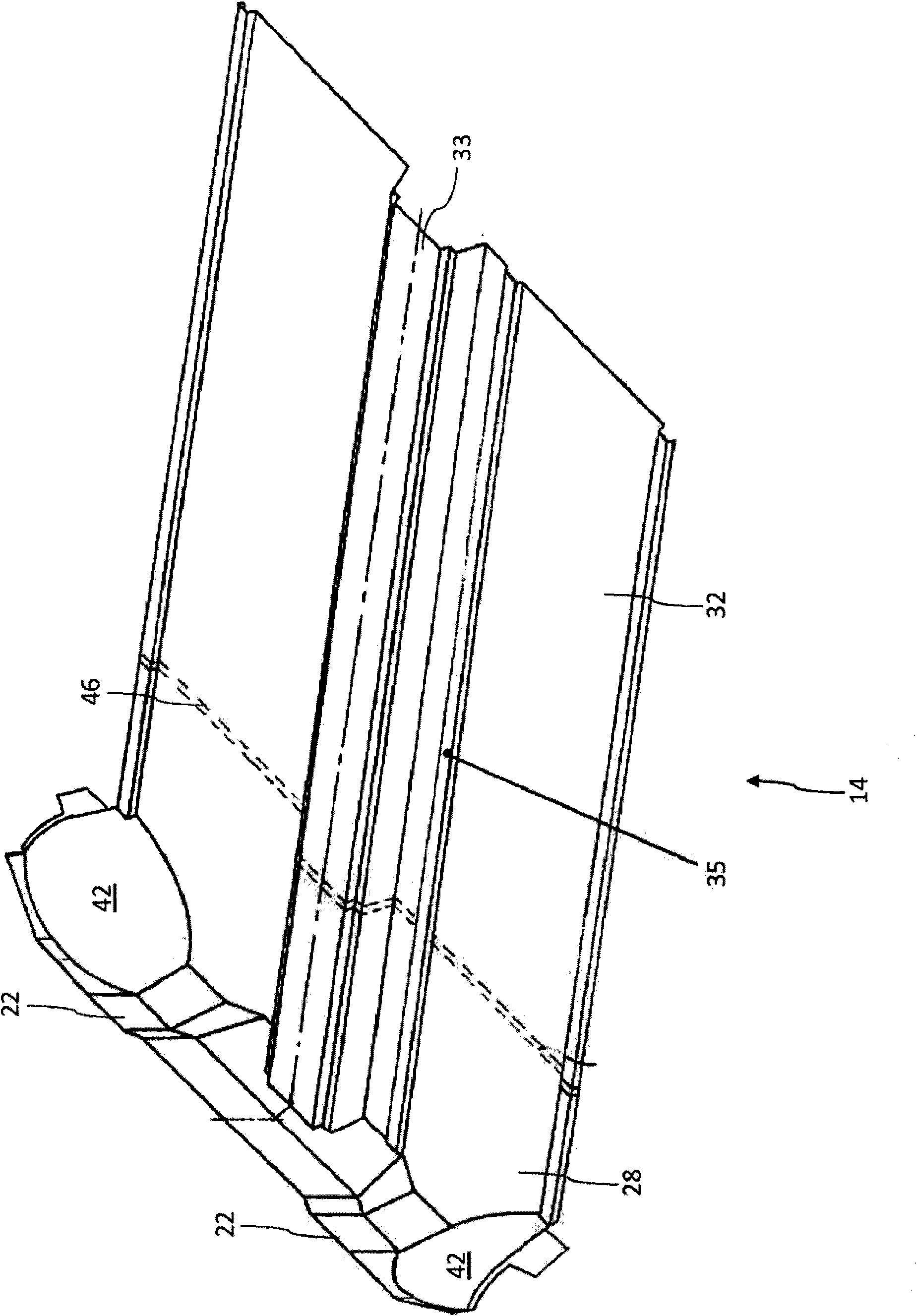

[0053] exist figure 1 Shown in the floor structure 10 of automobile body, this floor structure is at the front end, namely in press figure 1 In the illustration shown on the left, it adjoins the front frame 16 , 18 and at the rear end, that is to say on the right, adjoins the rear frame, usually a floor panel or a rear frame connection of the vehicle body. In this case, the floor structure 10 essentially consists of an inner load-bearing structure 12 , that is to say arranged in the dry area of the vehicle body, and a floor 14 below which is connected to the load-bearing structure 12 .

[0054] The inner carrier structure 12 has a plurality of interconnected or branched profile sections 20 , 23 , 24 , 26 , 34 , 40 . Almost all profile sections 20 , 23 , 24 , 26 , 34 , 40 are designed U-shaped in cross section and open downwards. The individual profile sections 20 , 23 , 24 , 26 , 34 , 40 are each welded to a flat section 28 , 32 of the base plate 14 lying below them with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com