Bearing-crankshaft intelligent press mounting method and system for scroll air-conditioning compressor

A technology of air-conditioning compressors and crankshafts, which is applied to manipulators, program-controlled manipulators, metal processing, etc., and can solve problems such as low automation, low manual assembly accuracy, and reduced service life of compressors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

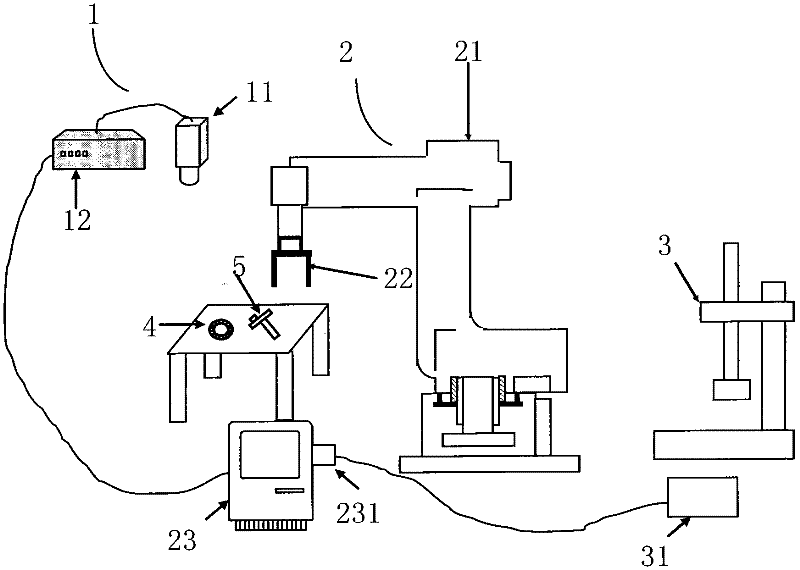

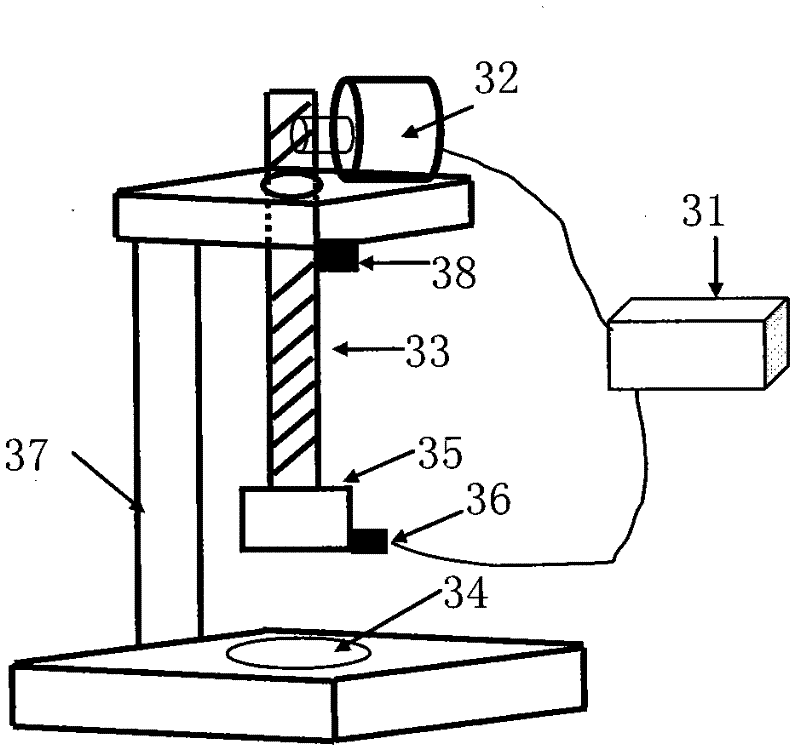

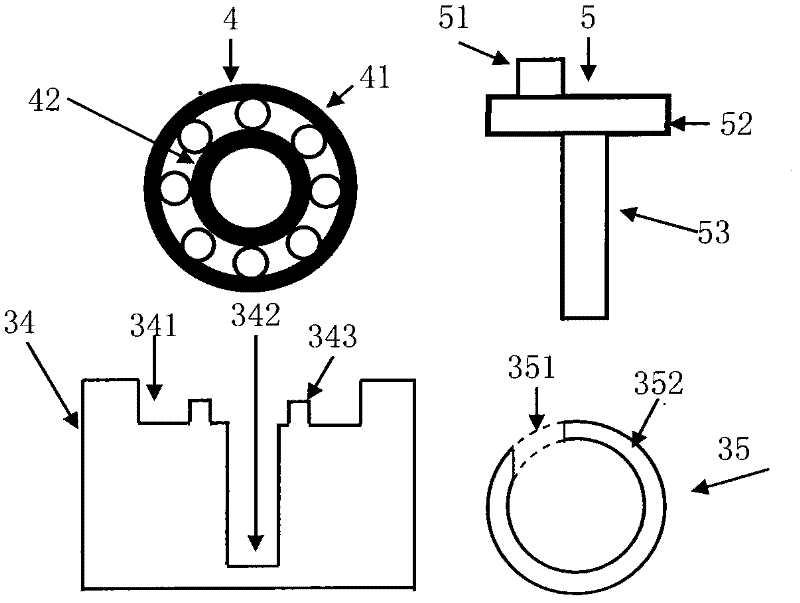

[0059] figure 1 Shown is a schematic diagram of the scroll air conditioner compressor bearing-crankshaft intelligent press-fitting system of the present invention, including a visual device 1, an industrial robot 2, and a press-fitting device 3, wherein:

[0060] The network communication interface of the vision device 1 is connected to the network communication interface of the industrial robot 2, and the industrial robot 2 receives the position signals of the bearing and the crank shaft output by the vision device 1, and processes the output position signals of the bearing and the crank shaft to generate The trajectory of the industrial robot 2; under the control of the generated trajectory, the industrial robot 2 grabs the bearing and places it in the press-fitting device, and grabs the crankshaft and places it in the bearing;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com