Concave shuttle wheel and double conical surface orbit structure of circular weaving machine

A double-cone surface and concave shuttle wheel technology is applied to circular looms, looms, textiles, etc., which can solve the problems of many wearing parts, high power consumption, and loud noise, and achieve lower noise, less wearing parts, The effect of improving work efficiency

Inactive Publication Date: 2011-06-15

黄美昌 +2

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, plastic circular looms are manufactured and used at home and abroad. There are four types of shuttle boats and running track structures. One is to rely on 4 shuttle wheels on the shuttle boat to run on the single-cone runway of the upper and lower door rings; The 4 shuttle wheels on the ship run on the plane stepped runway of the upper and lower door rings, and the anti-flying shuttle relies on the shuttle bottom plate to slide and rub on the gate track between the upper and lower door rings; the third type is to use the 4 shuttle wheels on the shuttle boat Run the anti-flying shuttle on the flat ladder runway of the upper and lower door rings, relying on the shuttle bottom plate to run on the roller track between the upper and lower door rings; The anti-flying shuttle runs on the type runway, relying on the 3-4 rollers at the bottom of the shuttle to run on the gate track between the upper and lower door circles by rolling friction; these four types of structures have different degrees of broken wires, flying shuttles, loud noise, Defects such as many wearing parts and high power consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

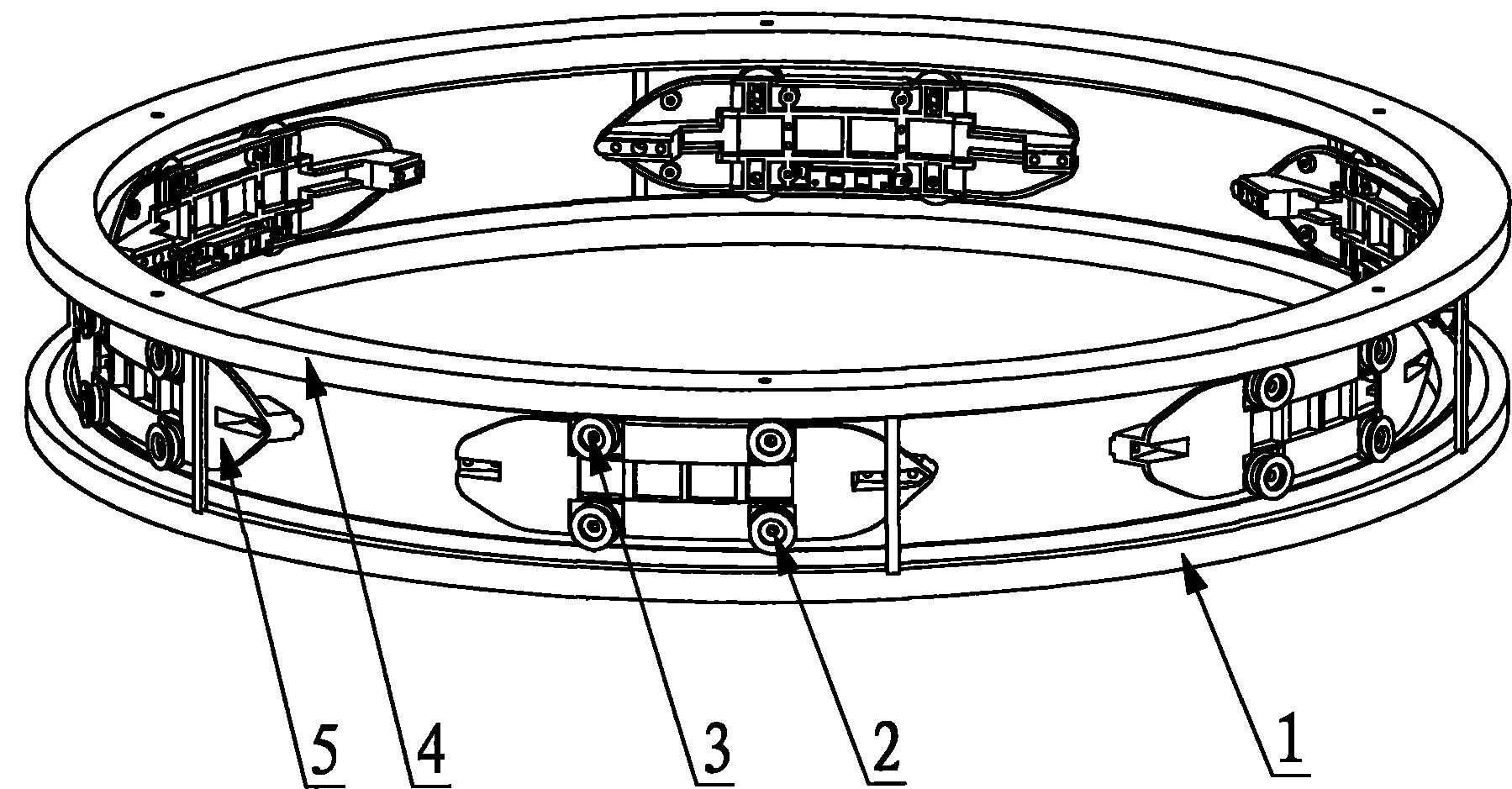

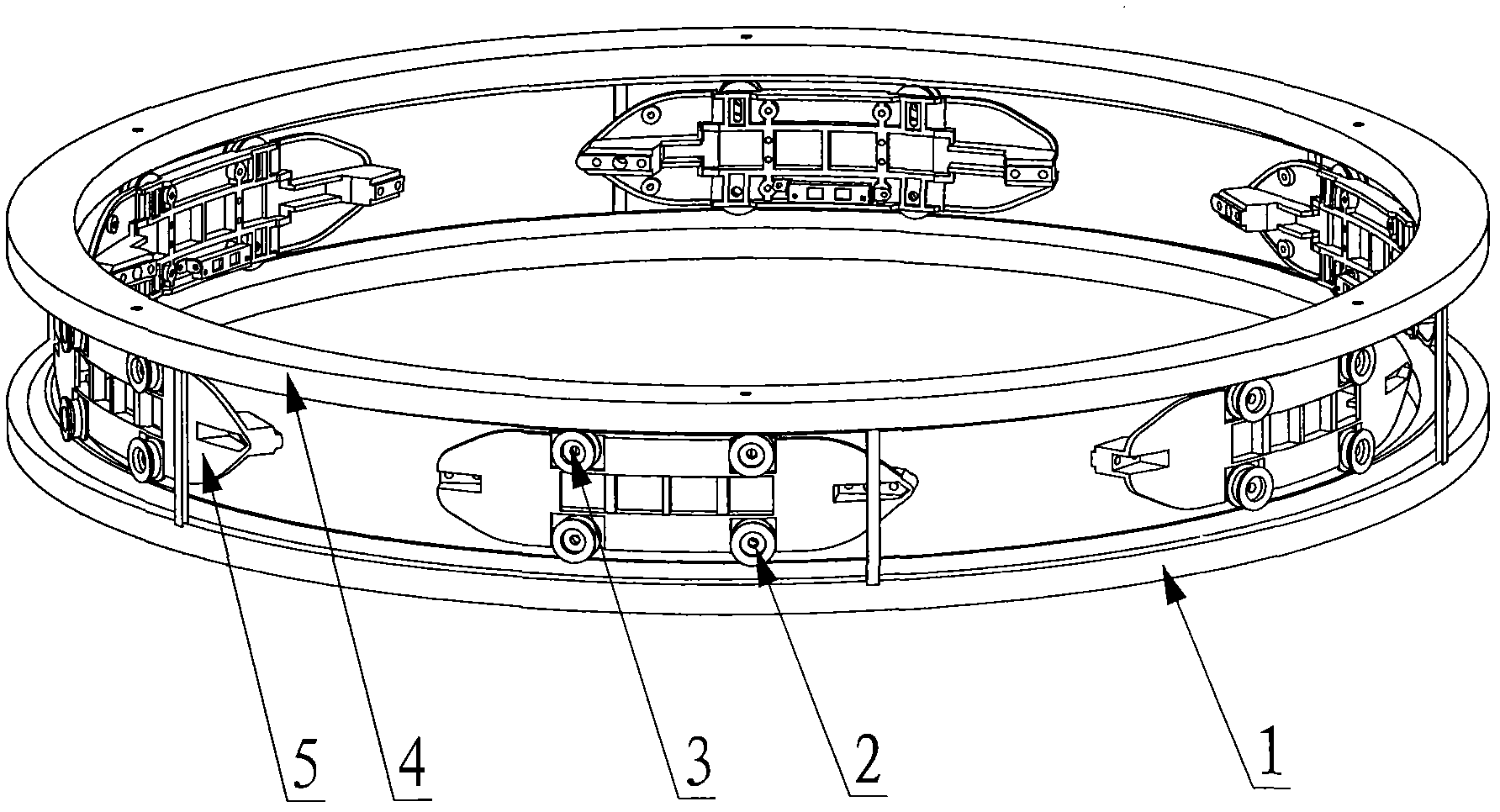

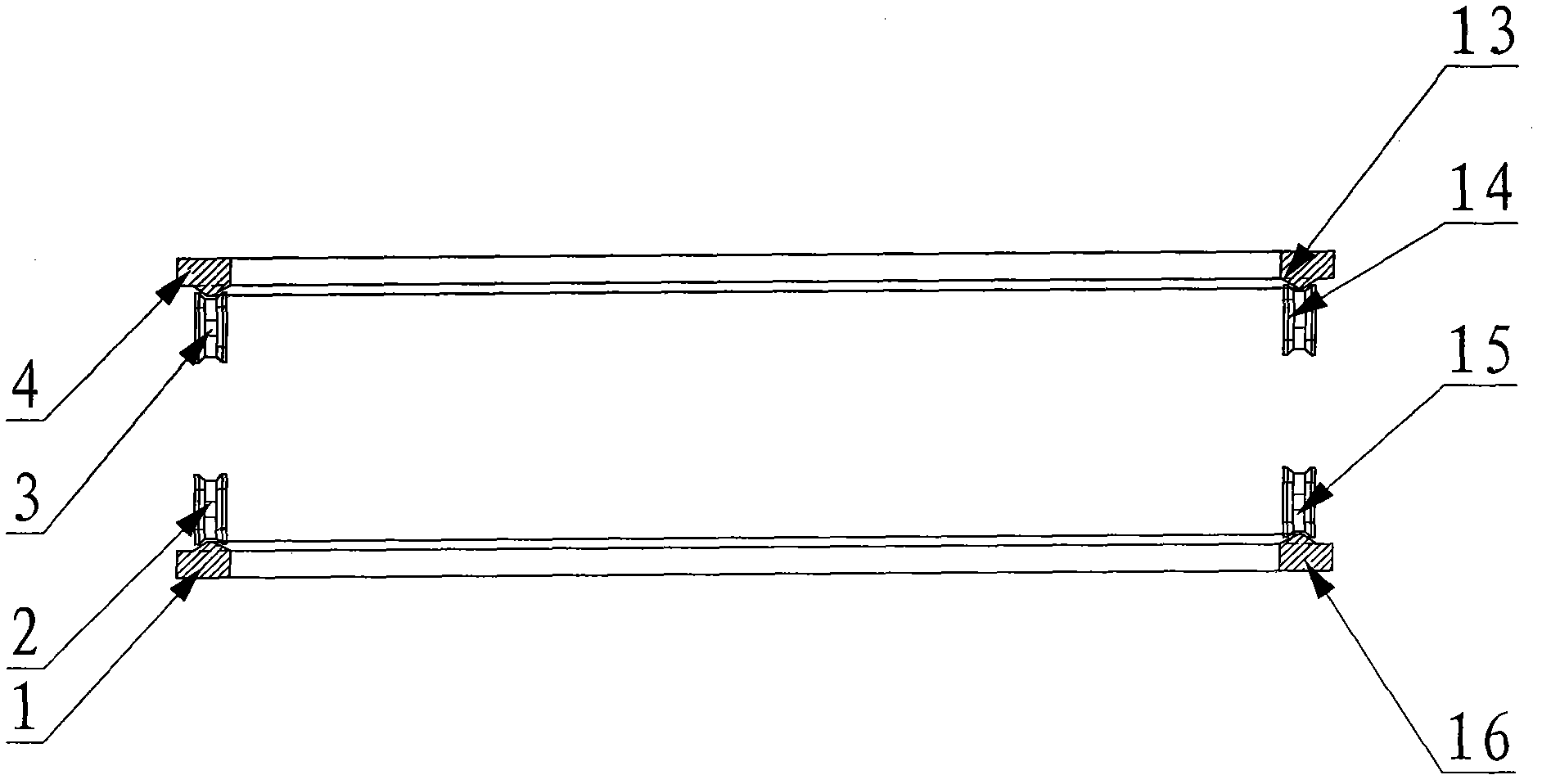

The invention relates to the field of plastic machinery, in particular to a concave shuttle wheel and double conical surface orbit structure of a circular weaving machine. The structure comprises a lower door ring, lower concave shuttle wheels, upper concave shuttle wheels, an upper door ring and a shuttle boat body, and the structure is characterized in that the lower edge of the upper door ring is designed into a double conical surface, the upper edge of the lower door ring is designed into a double conical surface, the shuttle boat body is arranged between the upper door ring and the lower door ring, the shuttle boat body is provided with four concave shuttle wheels, the two lower concave shuttle wheels and the double conical surface of the lower door ring are in rolling contact, the two upper concave shuttle wheels and the double conical surface of the upper door ring are in the rolling contact, and the concave shuttle wheels bear the centrifugal force of a whole shuttle when in operation to prevent shuttle flying. According to the invention, the defects of the shuttle boat and orbit structure on the circular weaving machine adopted at present are overcome, the operation is stable, the fault is less, the noise is low, quick-wear parts are less, the cost is low, and the electricity can be saved.

Description

A concave shuttle wheel and double-cone running track structure of a circular loom technical field The invention relates to the field of plastic circular looms, in particular to a concave shuttle wheel and a double-cone running track structure of a circular loom. Background technique At present, plastic circular looms are manufactured and used at home and abroad. There are four types of shuttle boats and running track structures. One is to rely on 4 shuttle wheels on the shuttle boat to run on the single-cone runway of the upper and lower door rings; The 4 shuttle wheels on the ship run on the plane stepped runway of the upper and lower door rings, and the anti-flying shuttle relies on the shuttle bottom plate to slide and rub on the gate track between the upper and lower door rings; the third type is to use the 4 shuttle wheels on the shuttle boat Run the anti-flying shuttle on the flat ladder runway of the upper and lower door rings, relying on the shuttle bottom plate t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D03D37/00

Inventor 黄美昌陈崇锡周传对

Owner 黄美昌

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com