High-fat Chlorella culture solution for promoting rapid growth and preparation method thereof

A technology for promoting growth and chlorella, applied in the biological field, can solve the problems of limiting chlorella photosynthesis and low chlorella biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

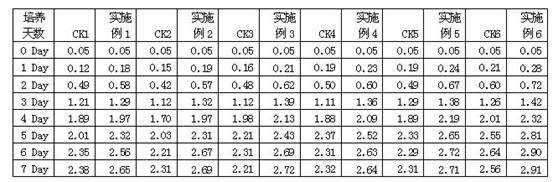

Examples

Embodiment 1

[0022] Put 30kg of bamboo vinegar into a 1000L stirred tank, then add 15kg of sodium nitrate, 20kg of potassium nitrate, 15kg of potassium dihydrogen phosphate and 15kg of sodium chloride, then add 1kg of ferric chloride, 1kg of boric acid, 1kg of copper sulfate, 1kg of manganese sulfate, 0.5kg of zinc sulfate and 0.5kg of ammonium molybdate, stir evenly, then add 900kg of water, stir until all substances are dissolved, and the final product is obtained.

Embodiment 2

[0024] Put 50kg of bamboo vinegar into a 1000L stirred tank, then add 25kg of potassium nitrate, 25kg of magnesium sulfate, 25kg of calcium chloride and 25kg of sodium chloride, then add 10kg of ferric chloride, 5kg of boric acid and 5kg of copper sulfate, stir evenly, and add 10kg of Add 820kg of water to the soil extract and stir until all substances are dissolved to form the final product.

Embodiment 3

[0026] Put 38kg of bamboo vinegar into the 1000L stirred tank, then add 17kg of sodium nitrate, 17kg of dipotassium hydrogen phosphate, 17kg of calcium chloride, 17kg of potassium dihydrogen phosphate and 17kg of sodium chloride, then add 2kg of copper sulfate, 2kg of manganese sulfate, 2kg of Zinc sulfate and 2kg ammonium molybdate, stir evenly, add 2kg soil extract, then add 867kg water, stir until all substances are dissolved, and the final product is served.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com