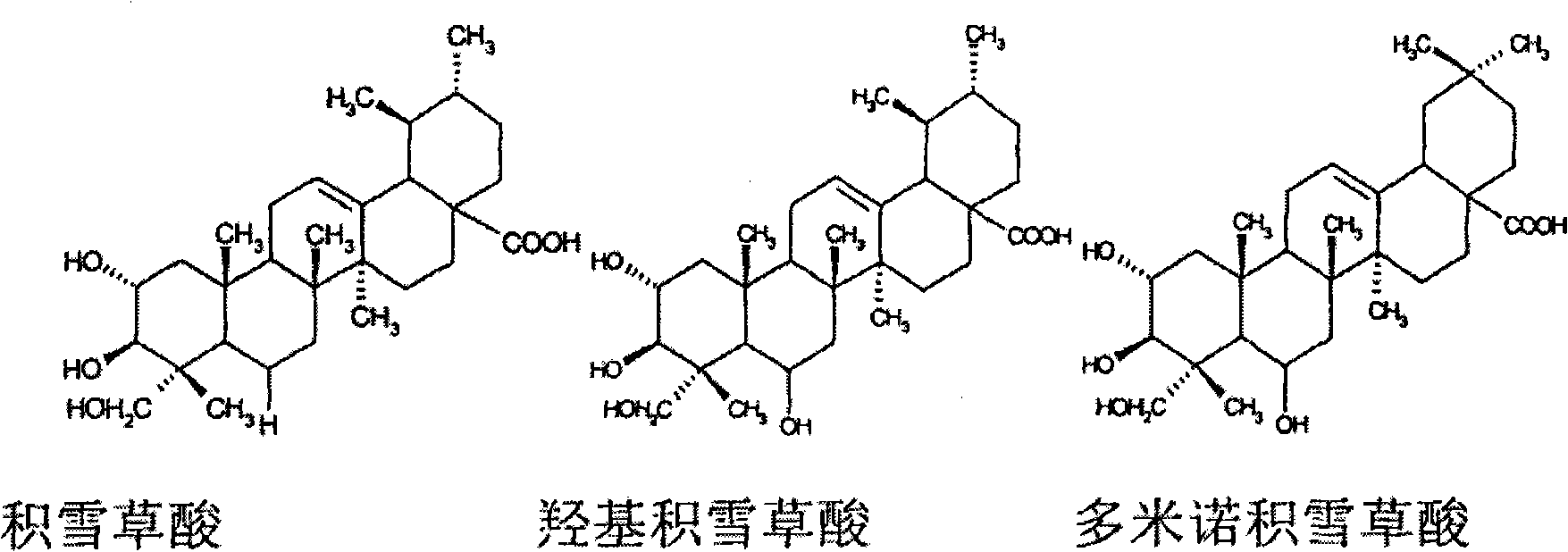

Method for extracting total triterpene of centella asiatica by enzymic process

A technology for extracting total glucosides of Centella asiatica and enzymatic method is applied in the field of medicine, which can solve problems such as increasing equipment investment, and achieve the effects of changing energy consumption, high extraction rate and improving extraction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 50kg of Centella asiatica hay, heat 250L of pure water in the extractor to 100°C, put the centella asiatica hay into the extraction tank after heating to inactivate the endogenous enzymes of Centella asiatica, during the inactivation process, the extraction tank The internal temperature is controlled at 95-100°C, after inactivation for 30 minutes, continue to heat at 100°C for 60 minutes, and collect the extract; then add 750L pure water to the extraction tank, control the water temperature at 40-50°C, adjust the pH to 6.0, add Cellulase, make the enzyme activity in the water reach 20-40u / ml, enzymatically hydrolyze for 1.5 hours, discharge the extract, collect the extract; combine the extract, separate the extract through a membrane with a molecular weight of 1500dalton, and intercept it into the solution Soluble protein and macromolecular organic matter are collected from the filtrate; the filtrate is then separated by a membrane with a molecular weight of 800dal...

Embodiment 2

[0026] Weigh 500kg of Centella asiatica hay, heat 2500L of pure water in the extractor to 100°C, put the centella asiatica hay into the extraction tank after heating to inactivate the endogenous enzymes of Centella asiatica, during the inactivation process, the extraction tank The internal temperature is controlled at 95-100°C, inactivated for 30 minutes, then kept at 100°C for 60 minutes, and the extract is collected; add 7500L of pure water to the extraction tank, control the water temperature at 40-50°C, adjust the pH to 6.0, and add fiber Suzyme, the enzyme activity in the water liquid reaches 20-40u / ml, enzymatic hydrolysis for 1.5 hours, the extract is discharged, and the extract is released; the extract is combined, filtered, the filtrate is first separated by a membrane with a molecular weight of 1500dalton, and retained in the solution Soluble protein and macromolecular organic matter are collected from the filtrate; the filtrate is then separated by a membrane with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com