Prestressing cradle frame of electrolysis bath

A cradle frame and electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve problems such as large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

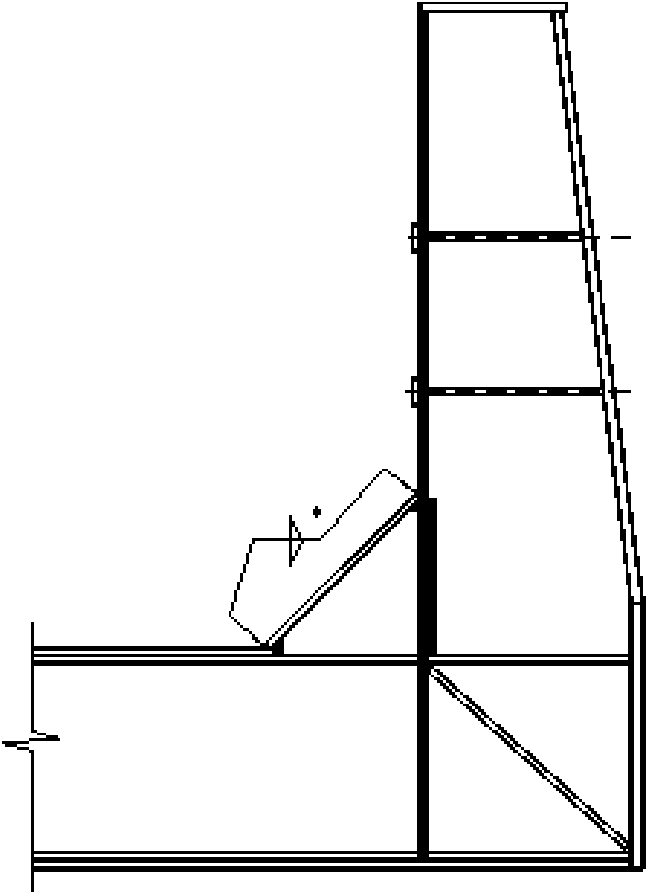

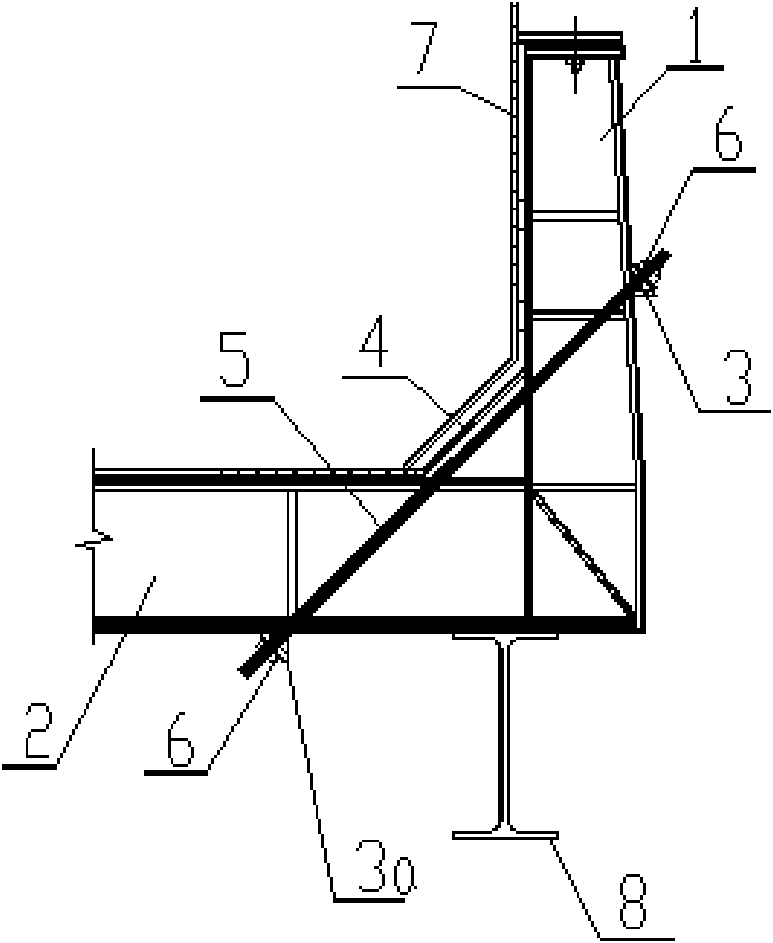

[0015] Embodiments of the invention: as figure 2 As shown, it includes the cantilever end 1 of the cradle frame, the bottom beam 2 of the cradle frame, the electrolytic tank shell 7, the AB beam 8 of the electrolytic cell, the upper end of the prestressed tension rod 5 is connected with the cantilever end 1 of the cradle frame, and the lower end is connected with the bottom of the cradle frame Girder 2 connection.

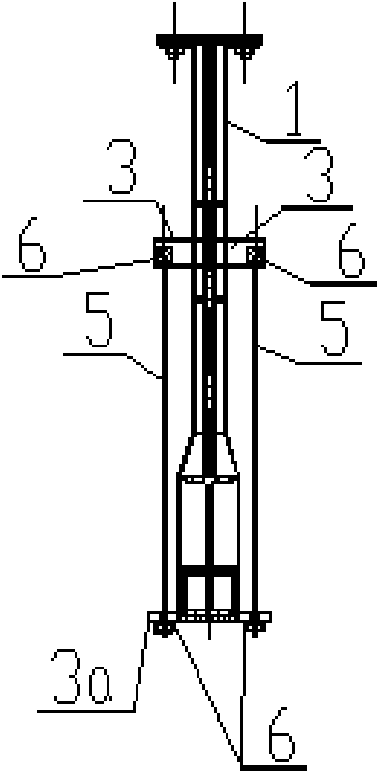

[0016] The number of prestressed tie rods 5 is two, which are respectively connected to both sides of the cantilever end 1 of the cradle frame and the bottom beam 2 of the cradle frame. From figure 2 Look, the two prestressed tie rods 5 are located at the front and rear sides of the cantilever end 1 of the cradle frame and the bottom beam 2 of the cradle frame. image 3 See, 2 prestressed pull rods 5 are located at the left and right sides of the cantilever end 1 of the cradle frame and the bottom beam 2 of the cradle frame.

[0017] On the cantilever end 1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com