Crank rocker type egg poking mechanism

A crank-rocker mechanism and crank-rocker technology are applied in the application, poultry industry, animal husbandry and other directions, which can solve the problems of single efficiency and function, high cost, complex grading actuator, etc., to reduce the cost of packaging equipment, Appropriate force for egg-picking action and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

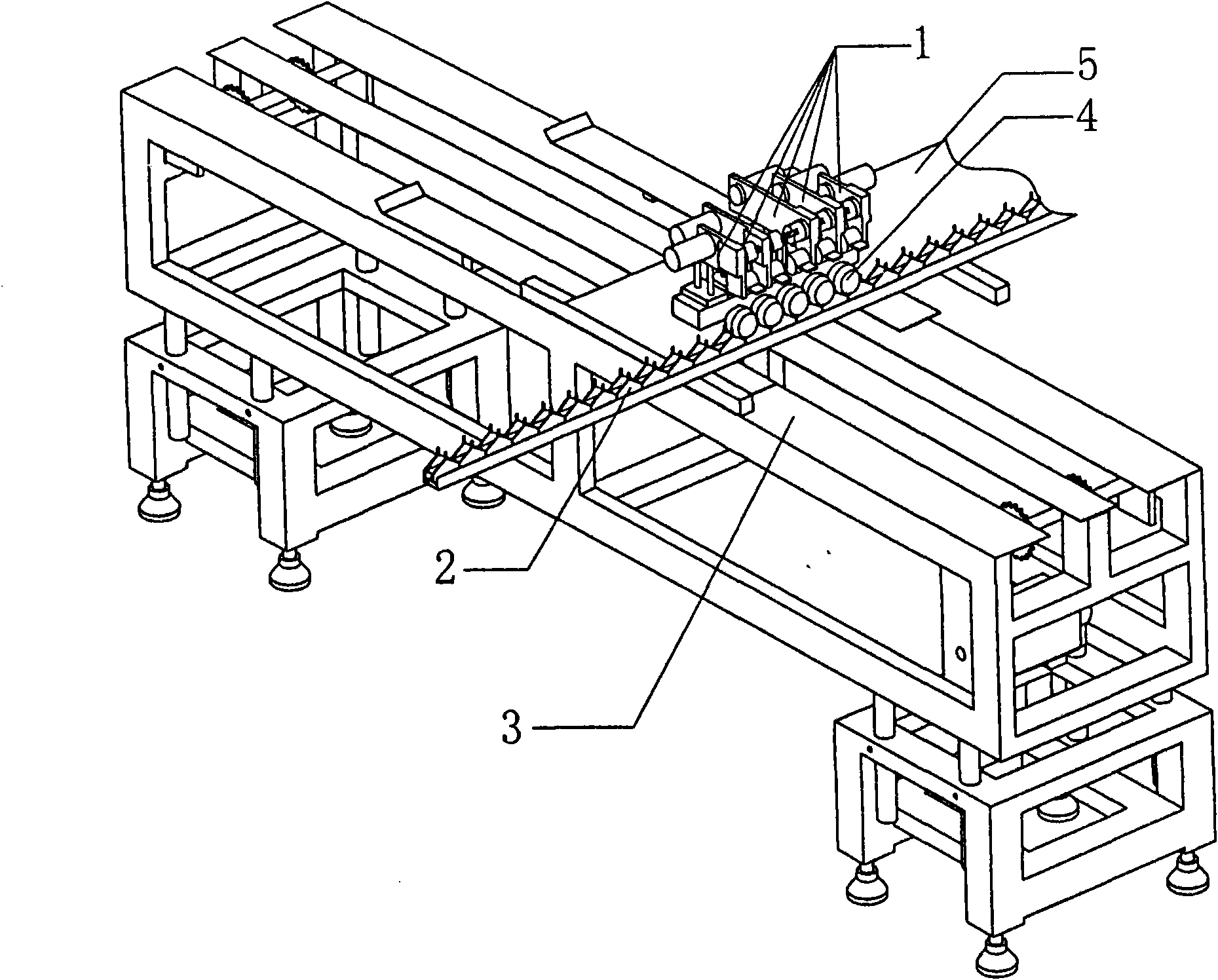

Image

Examples

Embodiment Construction

[0019] exist figure 2 Among them, motor 13 is fixed on the frame 10; Pulley 23 is fixedly connected with the output shaft of motor 13; Crank wheel 18 is also installed on the frame 10; Belt 24 is housed between crank wheel 18 and pulley 23, and crank wheel 18 The axis 18-4 (such as Figure 5 Shown) is connected with frame 10 by bearing 12, thus pulley 23 can drive crank wheel 18 to rotate.

[0020] Such as image 3 and Figure 5 As shown, the outer end surface of the crank wheel 18 is provided with a first chute 18-1, the crank 19 is fixedly installed in the first chute 18-1, and the position of the crank 19 in the first chute 18-1 can be adjust.

[0021] As a preferred embodiment of the present invention, the crank 19 is provided with a second chute 19-2, and the bottom of the first chute 18-1 is provided with a threaded hole 18-2, and the fastening screw 22 passes through the second chute 19. -2 and extend into the threaded hole 18-2, so that the crank 19 is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com