Multipoint temperature measuring device for thermoelectric refrigerating assembly

A technology of thermoelectric refrigeration and multi-point temperature, which is applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat. Solder joints, weak galvanic couples, etc., to save manpower, facilitate heat collection, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

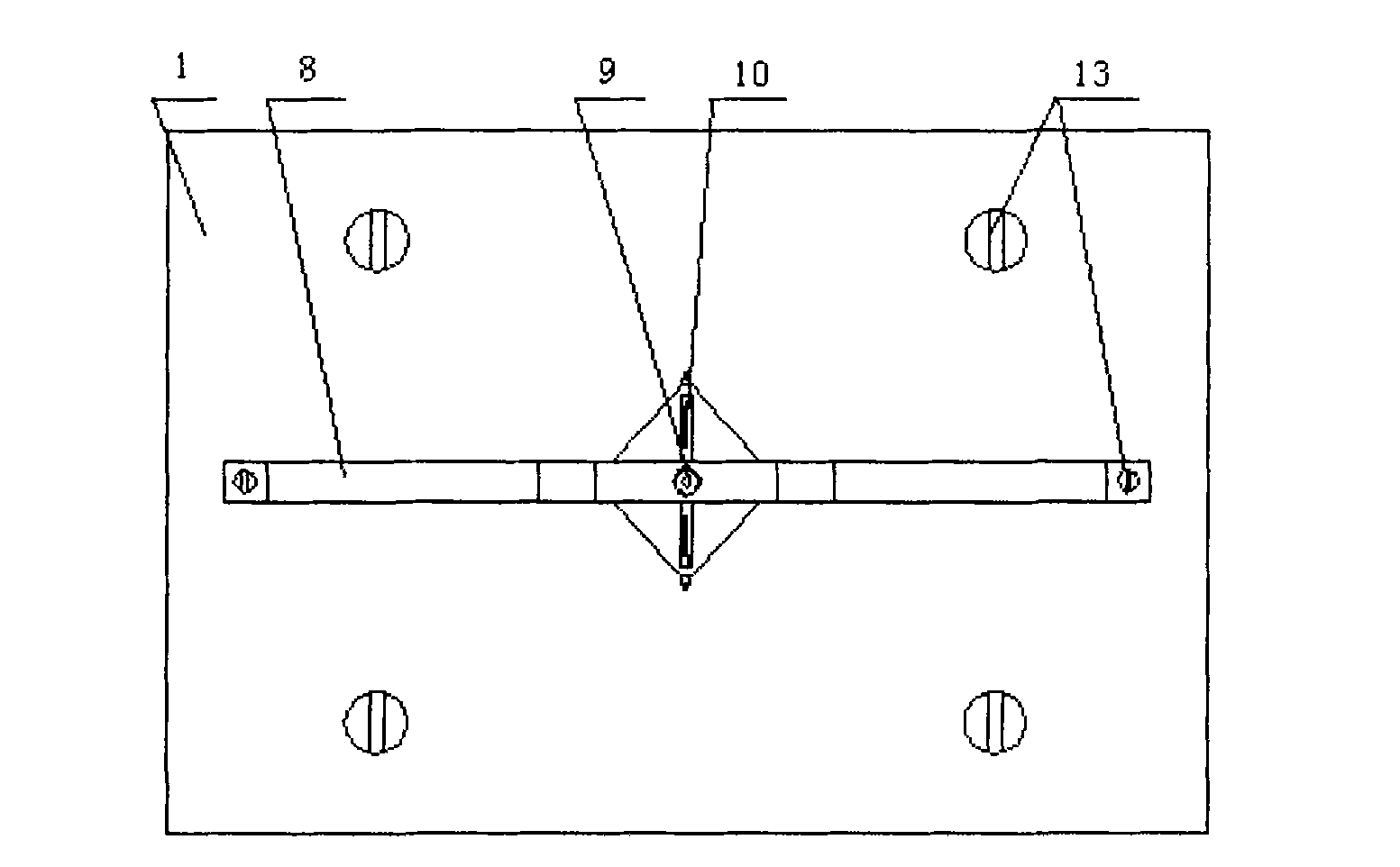

[0021] The multi-point temperature test device for thermoelectric refrigeration components is innovative in that it includes a housing 1, a positioning plate 2 fixed on the housing by fastening bolts 13, a boss-shaped temperature control platform 6 and a bracket 8, the positioning board and the convex There is a water jacket 3 and a temperature control refrigeration assembly 5 between the temperature control platforms from bottom to top; the top of the water jacket is close to the hot surface of the temperature control refrigeration assembly, and the cold surface of the temperature control refrigeration assembly is close to the temperature control platform. Below; there is a threaded support 9 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com