Vane pump

A vane pump and vane technology, used in pumps, pump components, rotary piston pumps, etc., can solve the problems of increased cost, difficult vanes to quickly extend, and need to be replaced, and achieve low manufacturing costs, superior performance, and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

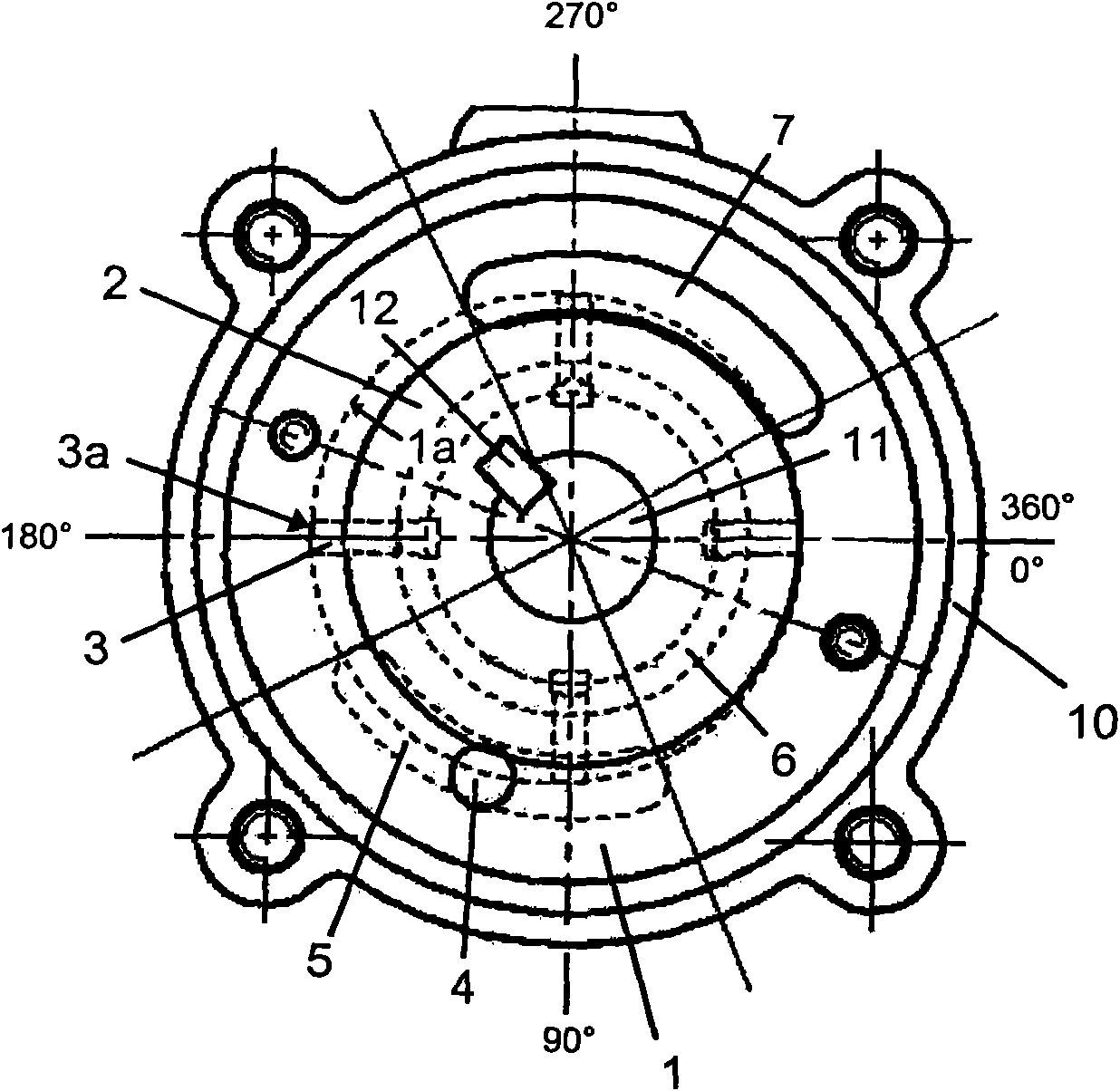

[0026] Preferred embodiments of the vane pump of the present invention are described below with reference to the accompanying drawings. In the example shown in the figure, the vane pump is a fuel pump used in an engine system to supply fuel. Obviously, the application of the present invention is not limited thereto.

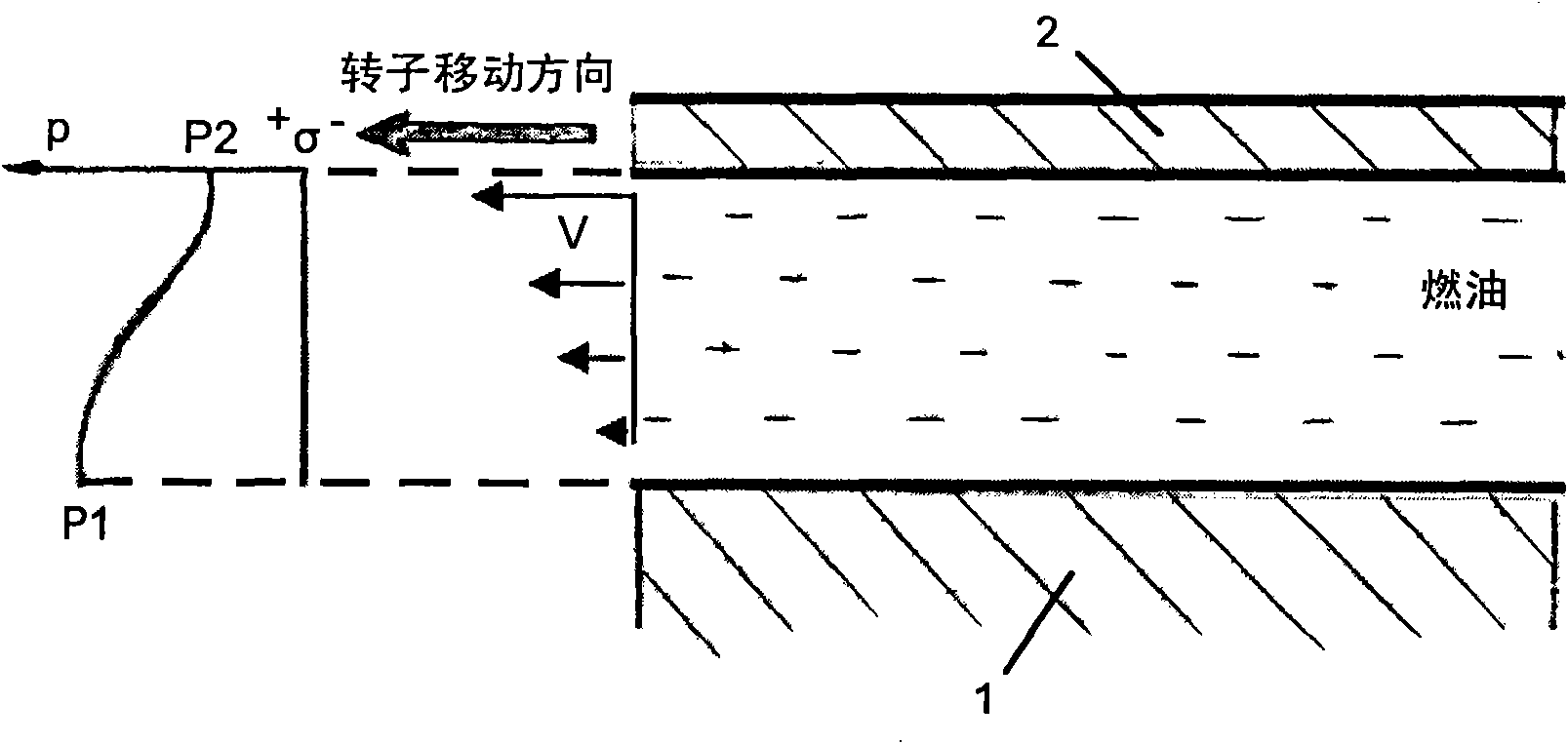

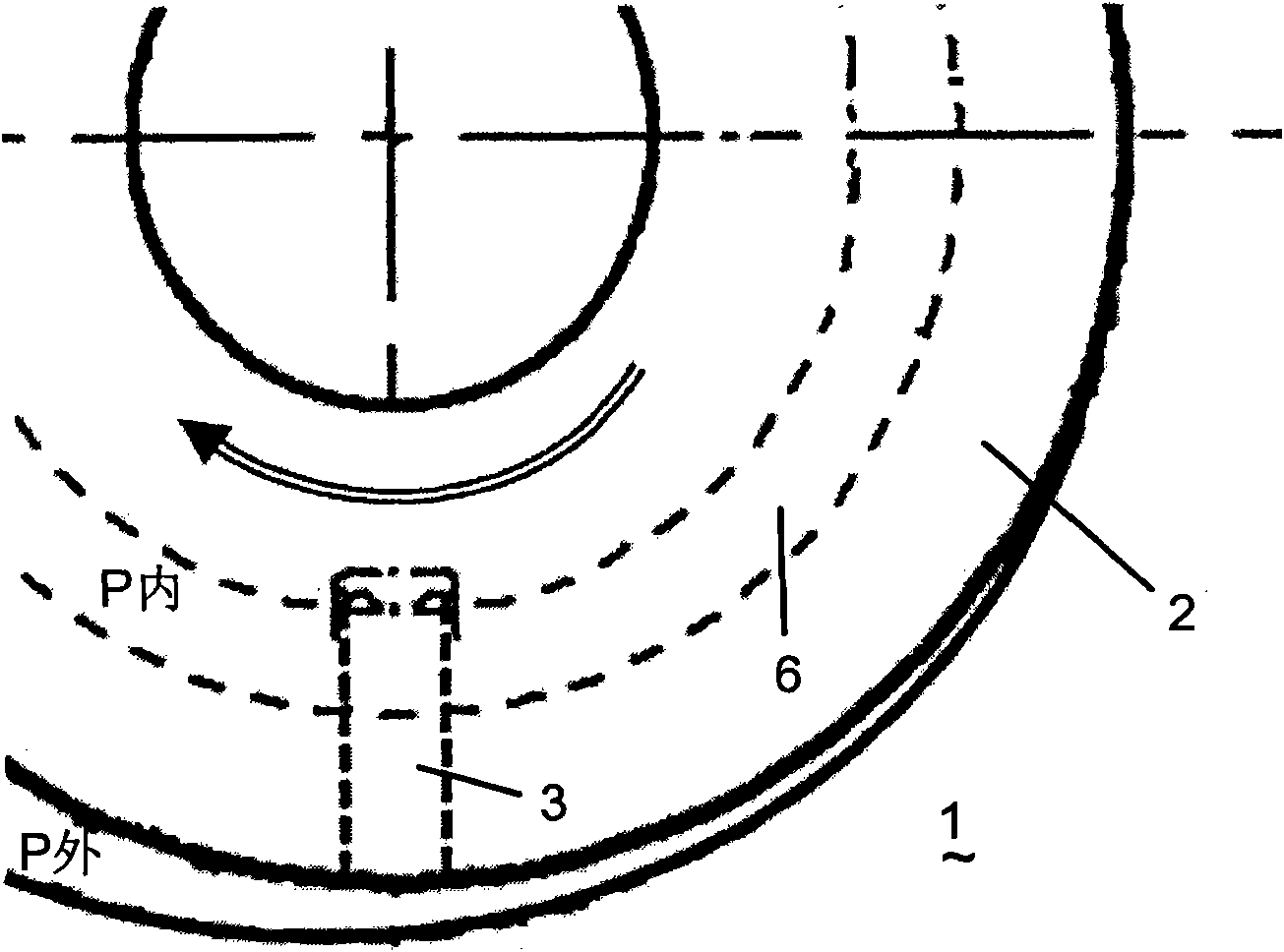

[0027] like figure 1 As shown, a vane pump according to the invention comprises a housing 10, a stator 1 fixed in the housing and a rotor 2 eccentrically accommodated in the stator. A plurality of vane slots are radially formed in the rotor 2, and the vanes 3 can reciprocally protrude and retract in the respective vane slots. An oil inlet 4 is formed in the stator 1, an oil inlet arc groove 5 communicated with the oil inlet 4, an oil discharge arc groove 7 set as a mirror image of the oil inlet arc groove 5, and an oil discharge arc groove 7 Connected oil outlet (not shown in the figure). The oil inlet arc groove 5 and the oil discharge arc groove 7 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com