Additive-free cold patch asphalt material and preparation method thereof

An additive-free, cold-filling technology, applied in the field of highway engineering construction materials, can solve problems such as grain loss

Inactive Publication Date: 2013-03-06

郭根才 +3

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

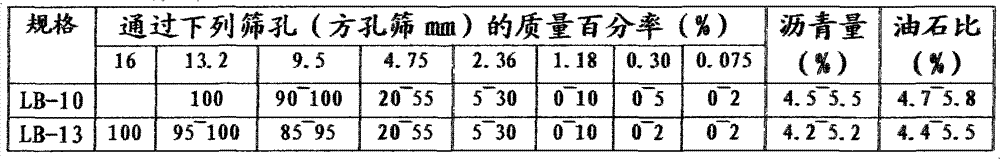

[0020] Cold-patched asphalt is a material used for pavement repair, which requires a wide range of adaptability. It can be used to repair both shallow potholes and deep potholes. For this reason, it is best to have two different grains, coarser and finer. diameter of the mixture, but the maintenance department is only willing to use a material of one specification, and at the same time, the coarser particle size is easy to cause particle drop, so the cold paving material should be designed as a finer graded mixture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

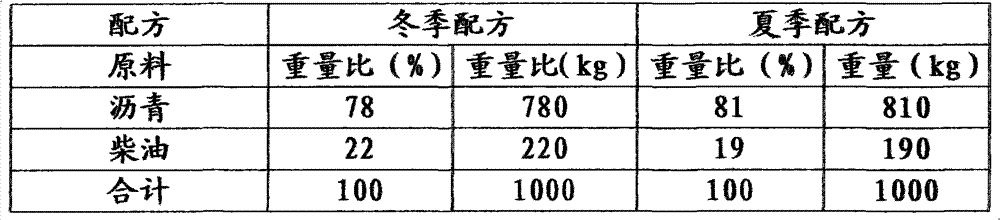

[0055] Proportion of liquid asphalt prepared with 90# asphalt

[0056]

[0057] Proportion of cold-patch asphalt

[0058]

Embodiment 2

[0060] Proportion of liquid asphalt prepared with 90# asphalt

[0061]

[0062] Proportion of cold-patch asphalt

[0063]

Embodiment 3

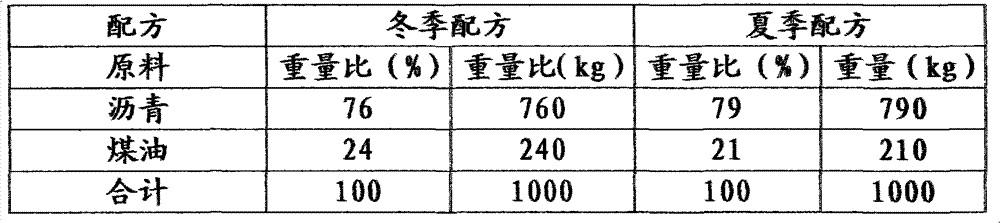

[0065] Proportion of liquid asphalt prepared with 70# asphalt

[0066]

[0067] Proportion of cold-patch asphalt

[0068]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an additive-free cold patch asphalt material and a preparation method thereof. The invention belongs to the technical field of road construction material. The material uses one of kerosene or diesel as solvent.The preparation method comprises the following steps: adding one of No. 90 road asphalt, No. 70 road asphalt and thermoplastic styrene-butadiene rubber (SBS) modified asphalt which are used as binders in one of kerosene or diesel according to a certain ratio to mix and obtain liquid asphalt, using a traditional hot mixture asphalt stirring device to mix the liquid asphalt with aggregate through a certain technology and prepare the cold patch asphalt material, cooling the cold patch asphalt material to the room temperature, and packaging with a sealed container for standby.

Description

1. Technical field [0001] The invention belongs to the category of road construction and belongs to the technical field of road engineering construction materials. 2. Background technology [0002] During the long-term use of asphalt pavement, there will be loose, potholes, peeling and other diseases. Pavement diseases not only reduce the service capacity of the pavement, but also affect the normal traffic of the road, and the potholes on the expressway may even cause traffic accidents. Therefore, the potholes and damages on the road surface need to be repaired in time. [0003] At present, hot-mix asphalt mixture is mostly used for repairing potholes on the road surface. It is feasible for road surface maintenance with concentrated locations and large engineering quantities, but for road surface maintenance with scattered locations and small engineering quantities, it is not only difficult to mix asphalt due to too little quantity. It is difficult for the plant to produce...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B26/26

Inventor 郭根才柯重基吴海虹俞兴祥赵友三庄泽堂林海陈为荣谢昌凯白永龙王鸽李菁

Owner 郭根才

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com