New bunker device

A new type of silo technology, used in packaging, large containers, transportation and packaging, etc., can solve problems such as increasing labor intensity and achieve the effect of good connection status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

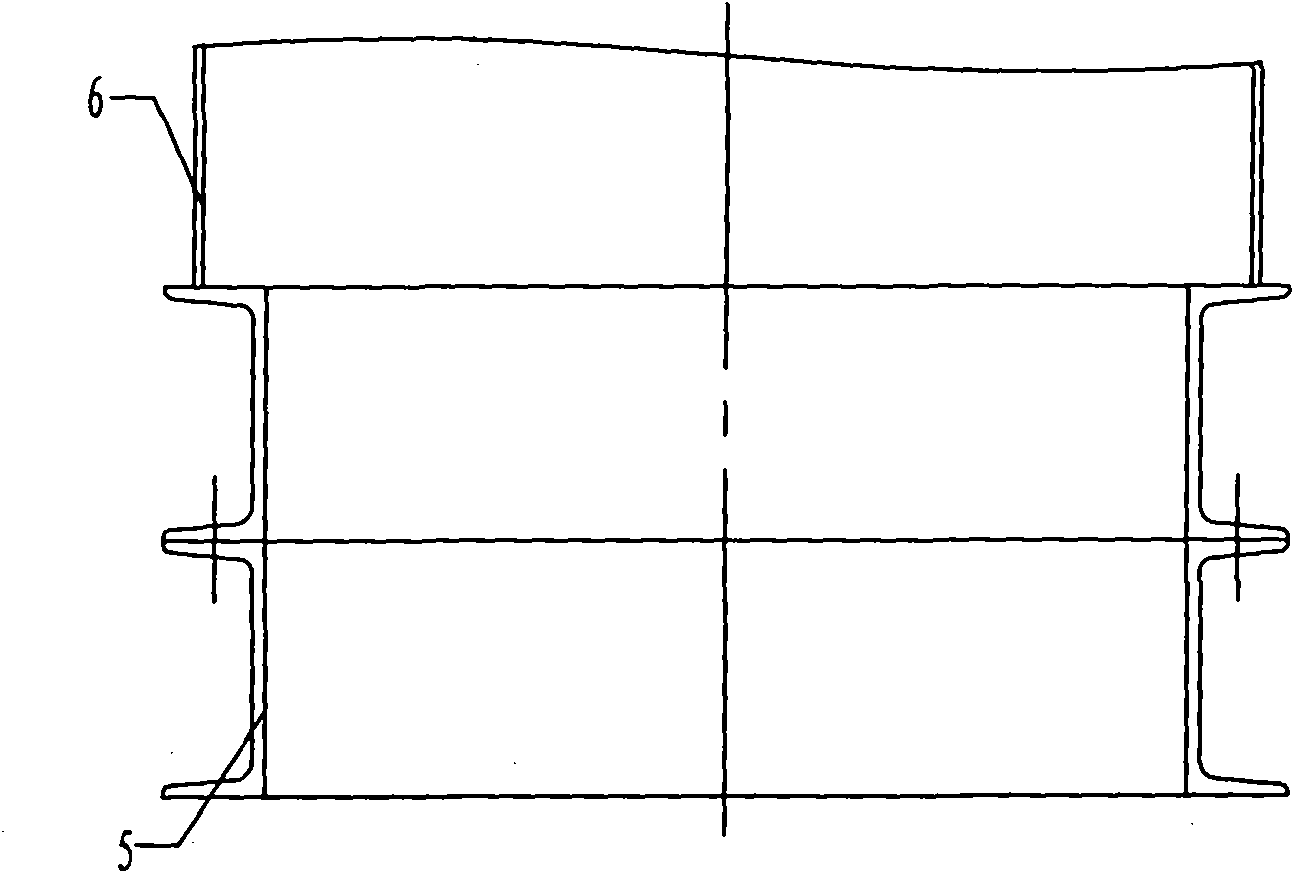

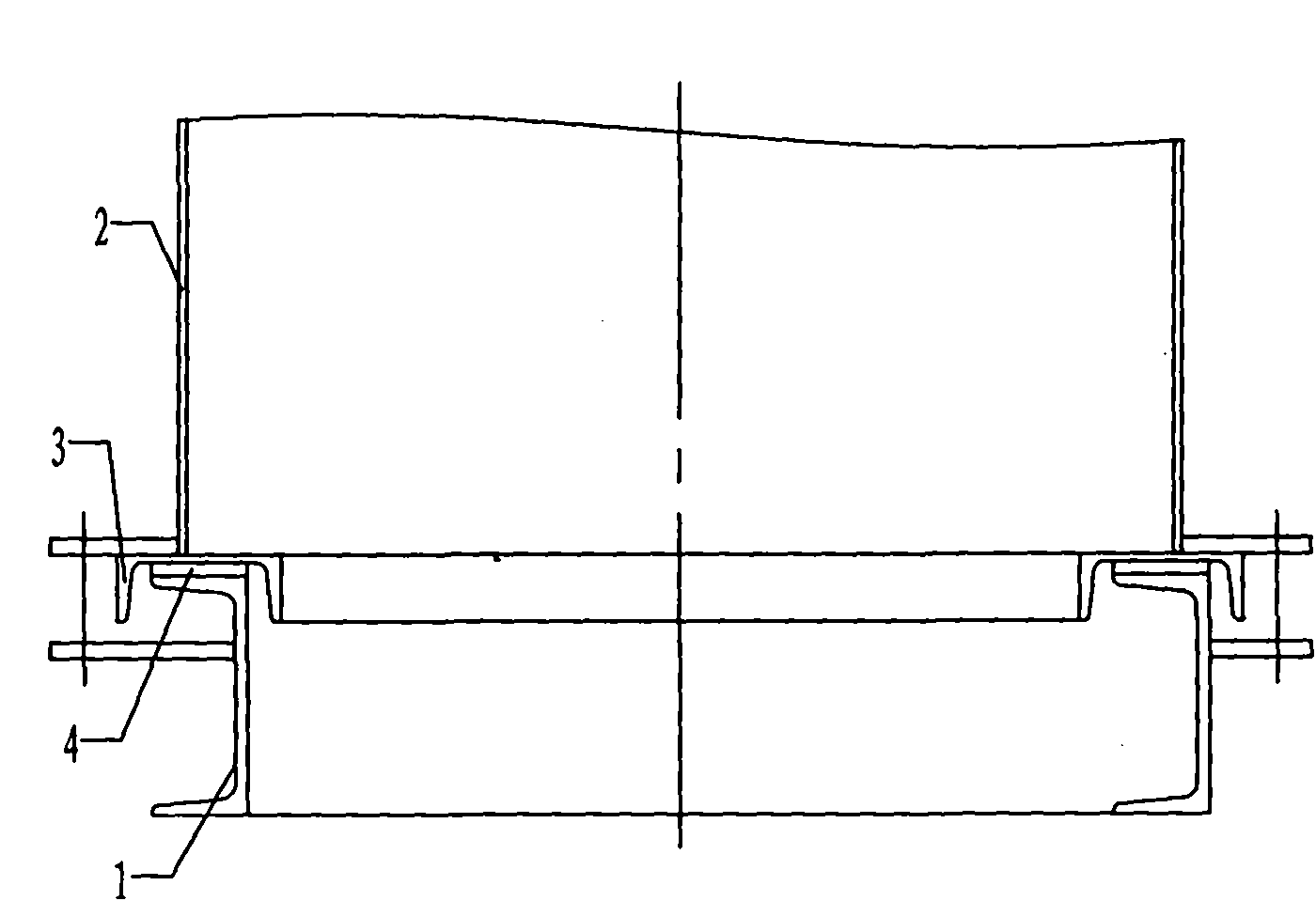

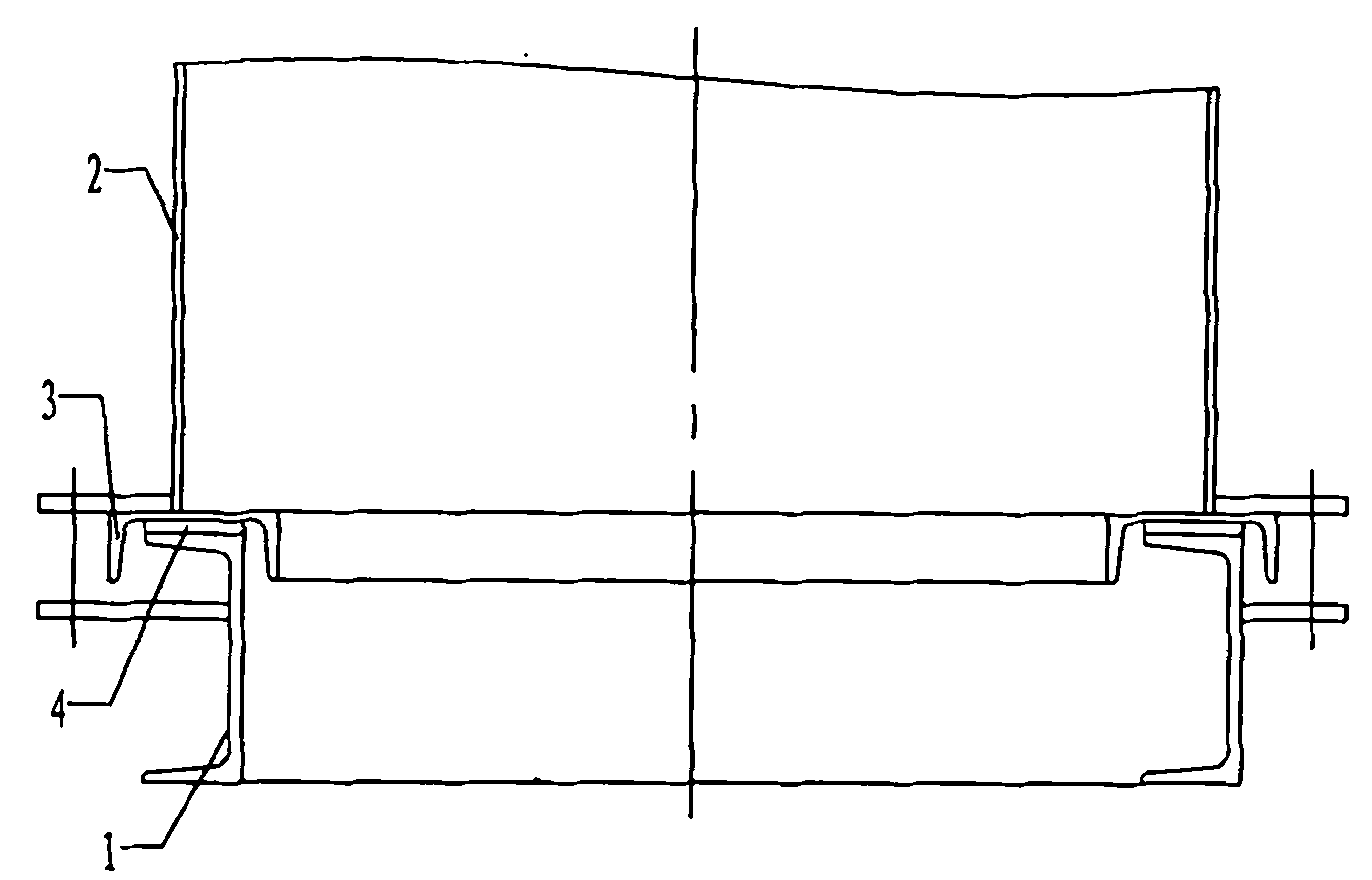

[0014] Such as figure 2 As shown, the embodiment of the silo device of the present invention includes a base 1, which is a cavity with an upper opening and a lower opening, and the base 1 is welded end to end by channel steel in sequence. The upper opening of the base 1 is fixedly connected with a silo 2 communicating with the cavity, and a week of channel steel 3 is welded at the bottom of the silo. 1 on the upper opening. A gasket 4 is pressed between the bottom of the draw-in groove and the upper opening of the base, and the feed bin presses down the gasket by gravity, so that the gasket 4 has the function of shock absorption and can well prevent dust from spilling out. In addition, horizontal connecting plates are respectively directly welded on the base and the silo, and the upper and lower opposite connecting plates are connected by bolts, which are not shown in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com