Automatic pipe-sticking machine

An automatic and tube machine technology, applied in the field of mechanical equipment, can solve problems such as low production efficiency, waste of manpower, and difficulty in unifying finished products, and achieve the effects of improving production efficiency, reducing labor intensity, and ingenious and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

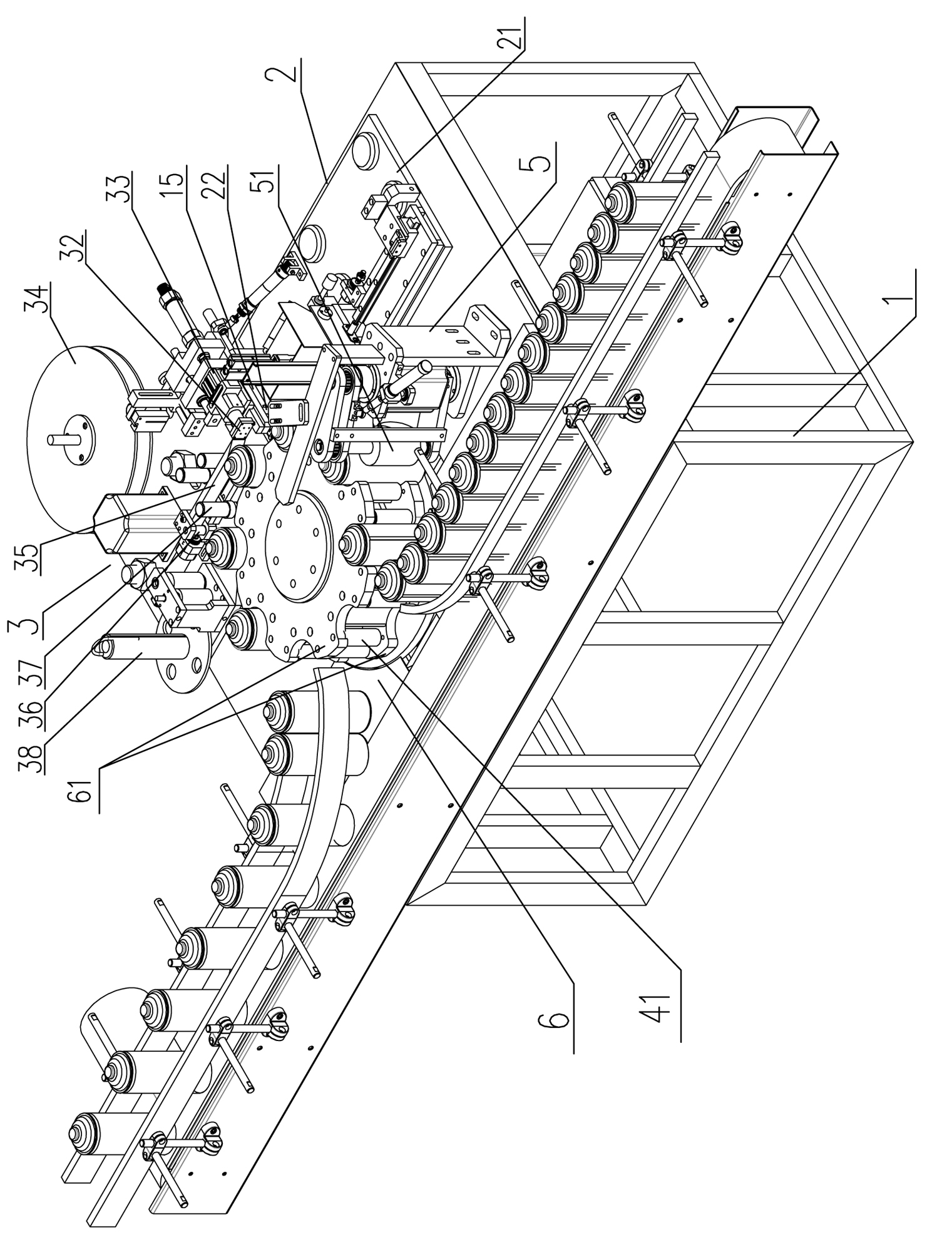

[0022] Taking the product to be attached as a bottled aerosol as an example, an example is given below:

[0023] refer to figure 1 , an automatic pipe sticking machine, which includes a frame 1, and the frame 1 is provided with a pipe discharge mechanism 2 and a glue paper mechanism 3. After the peripheral catheter is output from the pipe discharge mechanism 2, it can be removed from the glue paper mechanism The adhesive tape output in step 3 is pasted and pasted on the tube product to be pasted. Generally, the pipe outlet mechanism 2 is a mechanism for outputting the catheters of the peripheral devices. In addition to the implementation methods disclosed in this embodiment, it can also be implemented by manipulator clamping, high-pressure air spraying catheters, etc.; In addition to the implementations disclosed in this embodiment, the tape mechanism 3 can also be directly used by refitting an existing labeling machine.

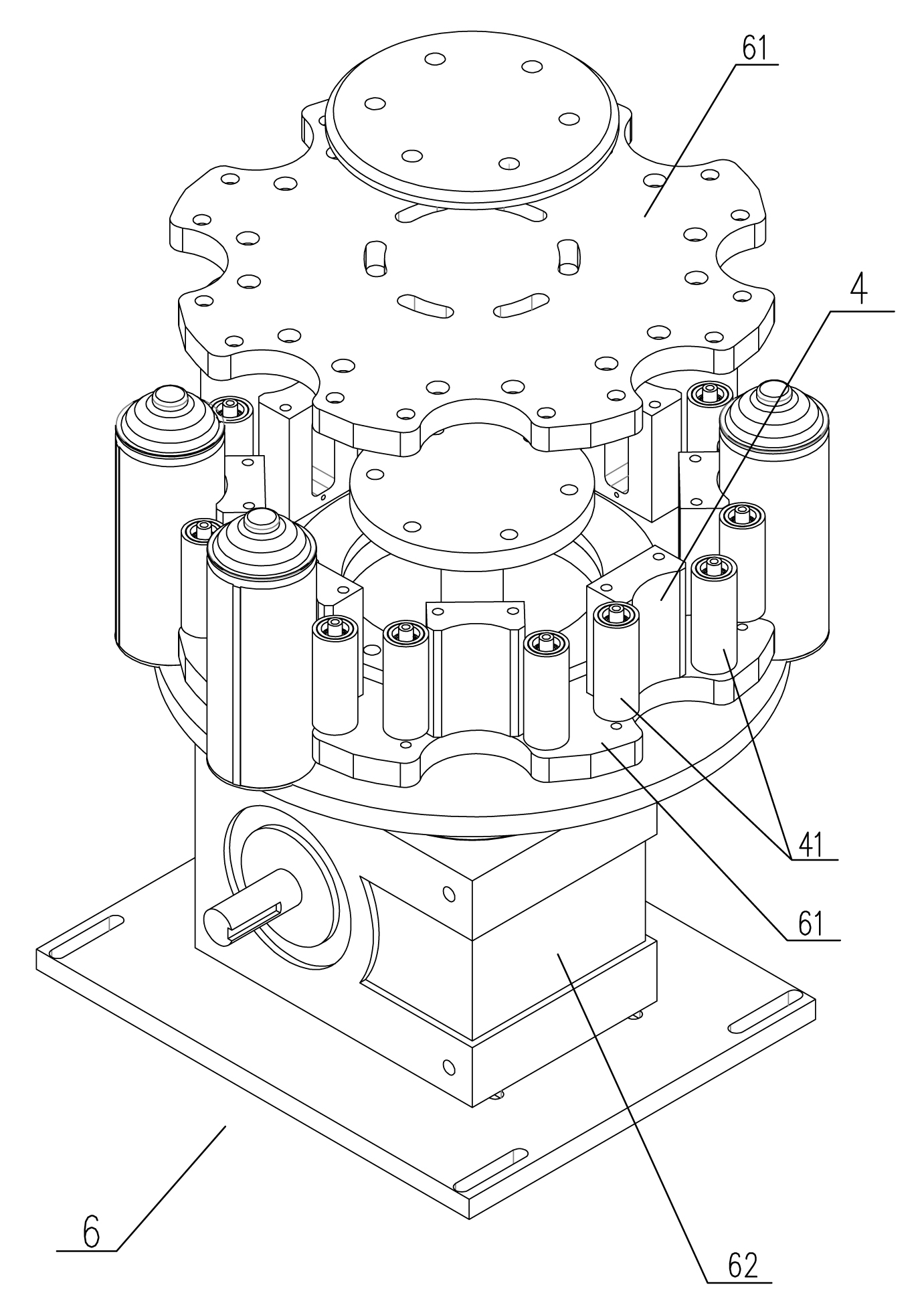

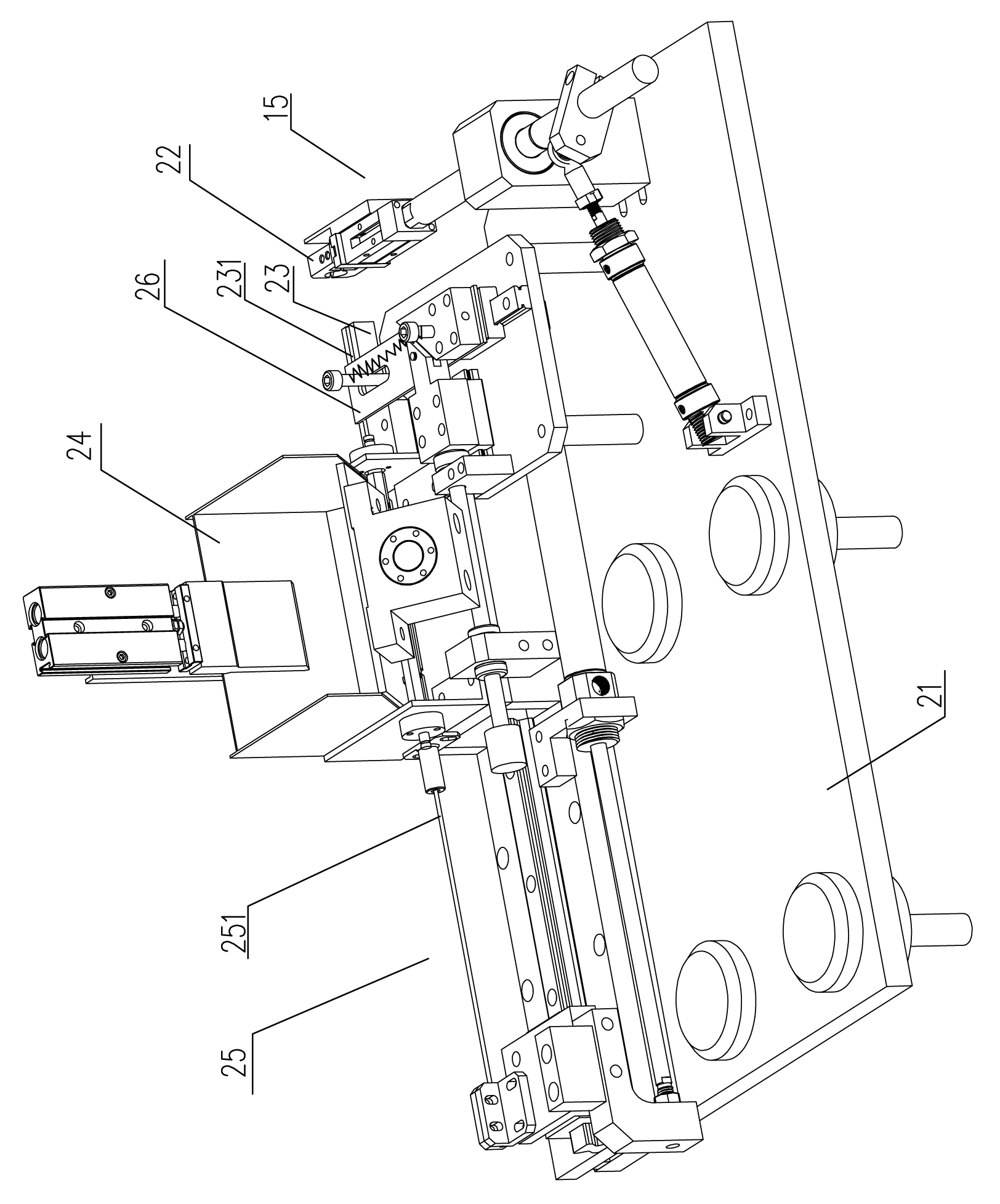

[0024] refer to figure 1 with figure 2 , further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com