Double-layer top layer of shunting locomotive

A shunting locomotive, double-deck technology, applied to railway car body parts, railway vehicle traction devices, transportation and packaging, etc., can solve problems such as high temperature, no radiation protection and heat insulation, and insufficient heat dissipation function of locomotives, so as to enhance rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with accompanying drawing, the present invention will be further described:

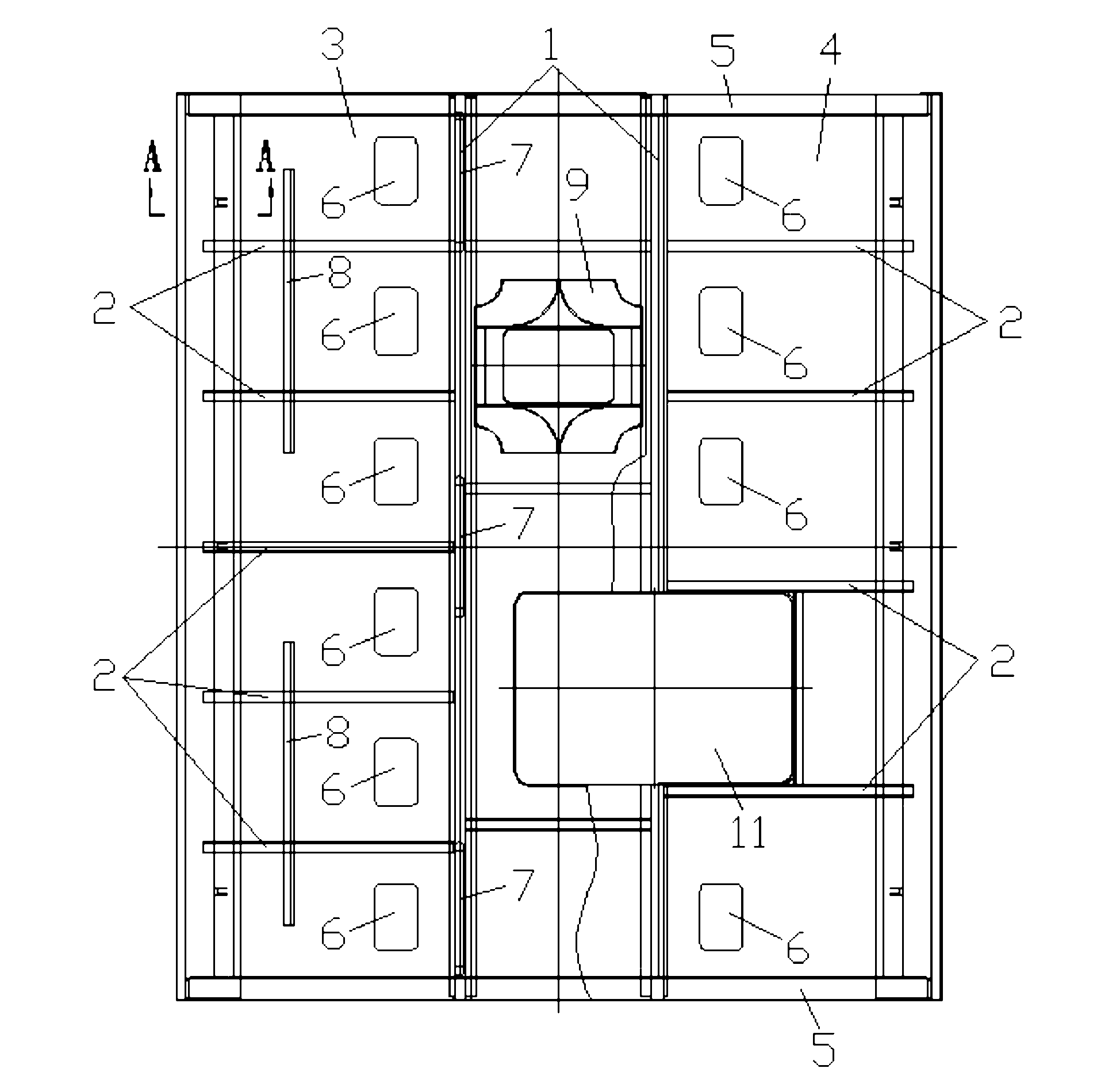

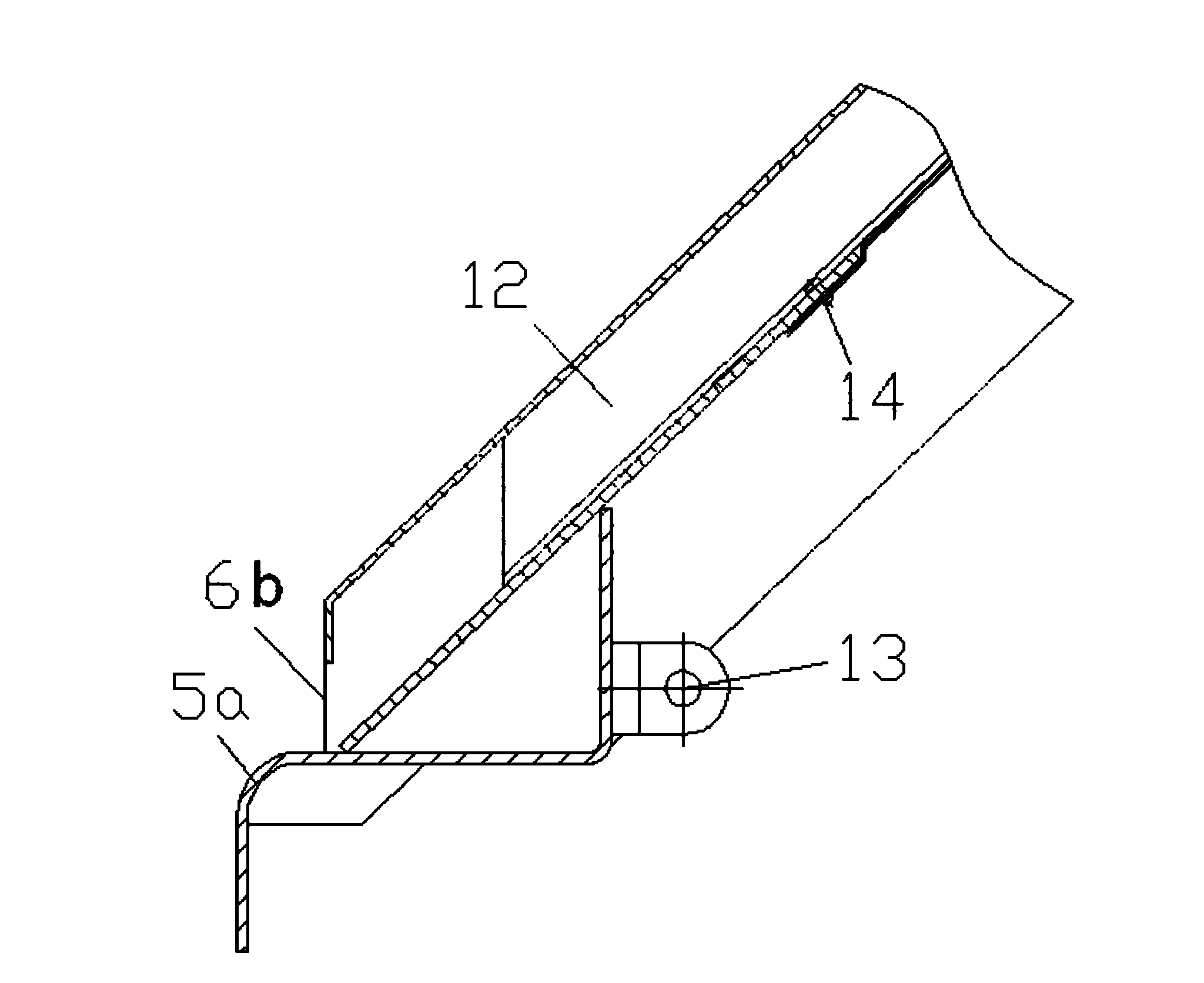

[0020] figure 1 , 2 , 3 shows the frame structure of the double-layer top layer of the shunting locomotive. In the figure, the frame structure of the double-layer top layer of the shunting locomotive is connected together by two pot-shaped longitudinal beams 1 and 12 groove-shaped cross-beams 2 . There is a flat top slab 10, and a downward sloping structure is adopted on both sides of the top slab 10, and a longitudinal waterproof eaves 5a are arranged at the lowest point on both longitudinal sides of the frame structure, and horizontal waterproof eaves 5 are arranged on both lateral sides; the frame structure The outer side of the inclined part is provided with an outer skin 3, and the inner side is provided with an inner skin 4 with an inner air inlet 6 to form a hollow double-layer structure 12, and a side air outlet 6b is provided at the lowest point of the hollow doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com