Novel energy collecting primer

A detonator and energy-gathering technology, which is applied in blasting and other directions, can solve the problems of rising production cost of the detonator, large charge of the detonator, and difficulty in ensuring the detonation sensitivity of the detonator, so as to achieve the effect of reducing cost and reducing the amount of charge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

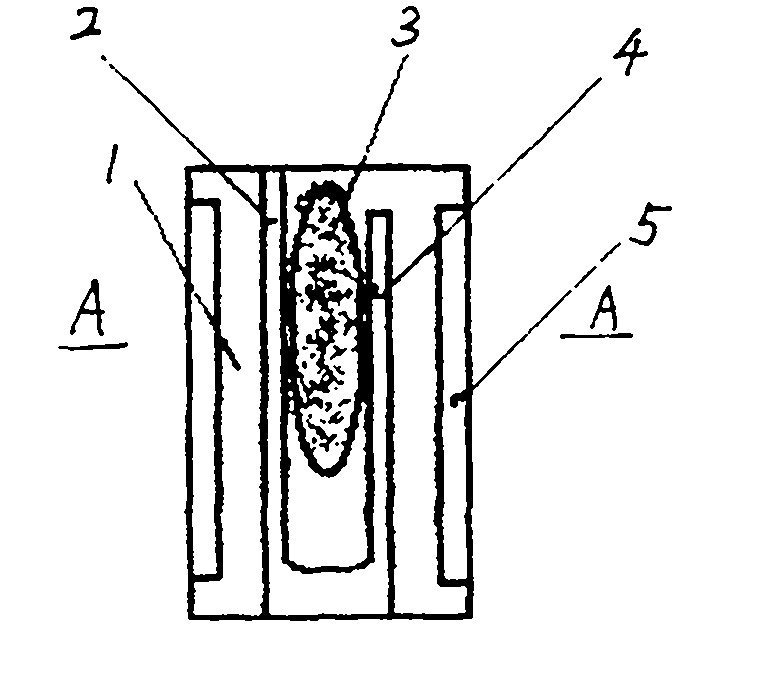

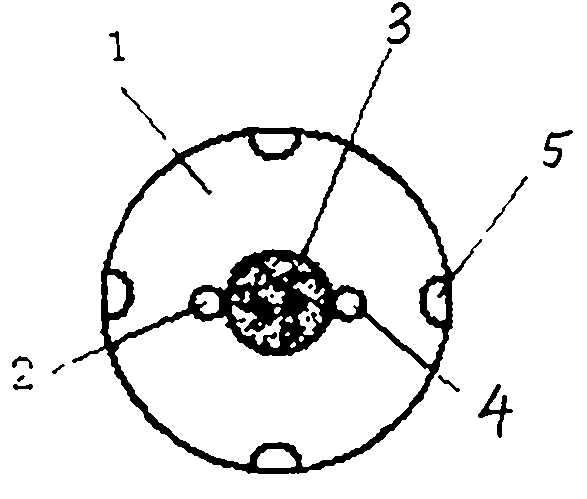

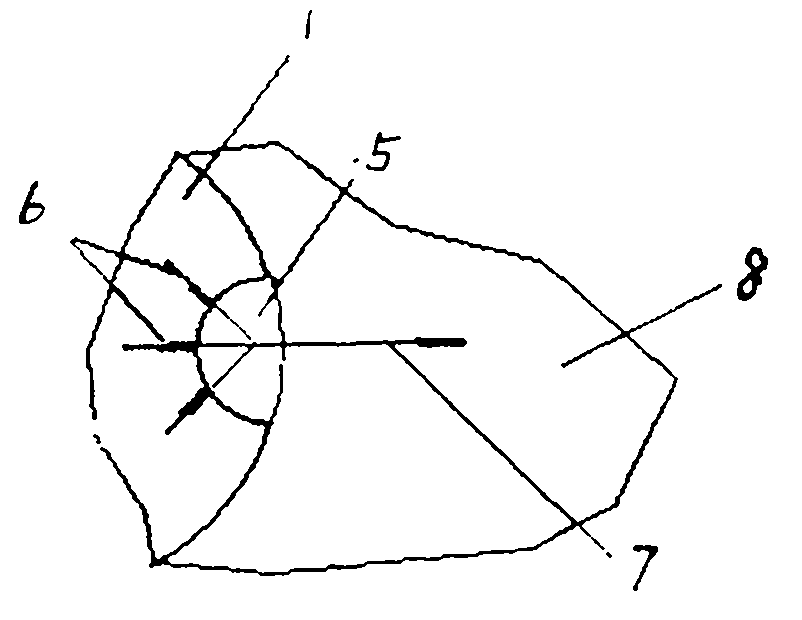

[0011] A new type of energy-concentrating detonator, which is provided with a detonator 3 on the central axis near the detonation point of the through hole 2 of the detonator detonator; the detonator is an independent explosive unit, which is installed in the In a capsule and sealed; the charge of the detonator is not less than 10g / piece; 3 to 8 arc-shaped closed energy-gathering semicircular grooves 5 are evenly distributed on the outer wall of the detonator, and the grooves are closed In the outer wall of the packaging tube, the groove is filled with air, which is the growth space for the detonation wave generated during the detonation of the detonator and the energy-gathering jet 7 of the reaction product 6 .

[0012] Such as figure 1 , the detonator is inserted into the detonator from the through hole 2, pierced through the other end, and then inserted back into the detonator hole 4, and the detonator can be put into the detonated blast hole by tightening the detonating wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com