Microwave oven without magnetron

A technology without magnetrons and microwave ovens, applied in the field of microwave ovens, can solve problems that are not conducive to the miniaturization of microwave ovens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

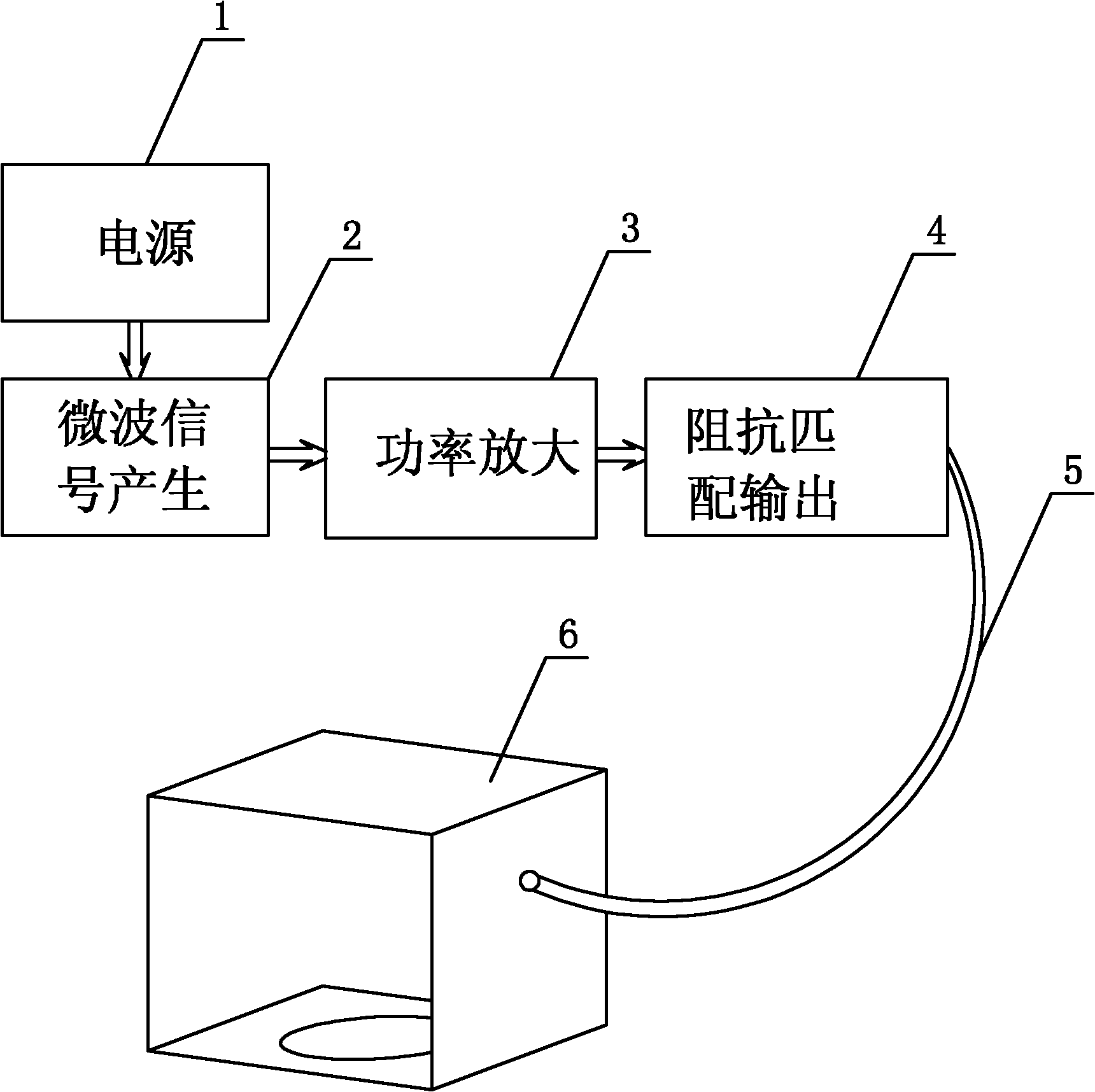

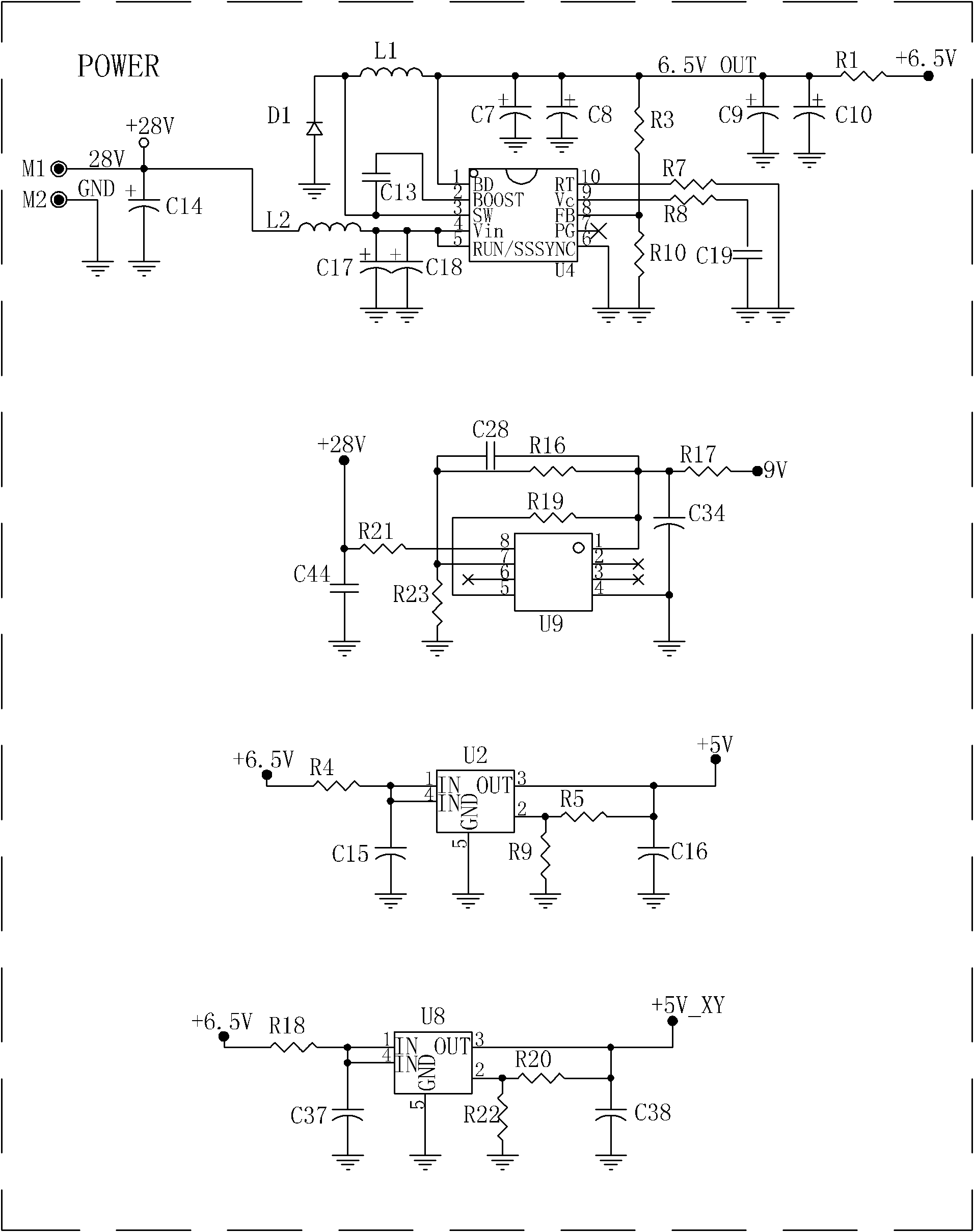

[0022] see figure 1 and figure 2 , the non-magnetron microwave oven, including an oven chamber 6, a control circuit, a microwave signal generating module 9 that replaces the magnetron and generates a microwave signal that meets cooking requirements, a microwave antenna 5 that transmits the microwave signal to the oven chamber, and A power circuit 1 that provides working power for the control circuit and the microwave signal generating module. The microwave signal generation module 9 includes a microwave signal generation circuit 2 and a power amplification circuit 3 .

[0023] The microwave signal generating circuit 2 includes an oscillation circuit for generating microwave signals of 2450 MHz or 900 MHz. The power amplifying circuit 3 includes a microwave signal coupling circuit, an amplifying circuit and an output coupling circuit, wherein the amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com