Transport device for conveying printed products

一种传输机构、印刷品的技术,应用在输送机、运输和包装、物件供给等方向,达到安装简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

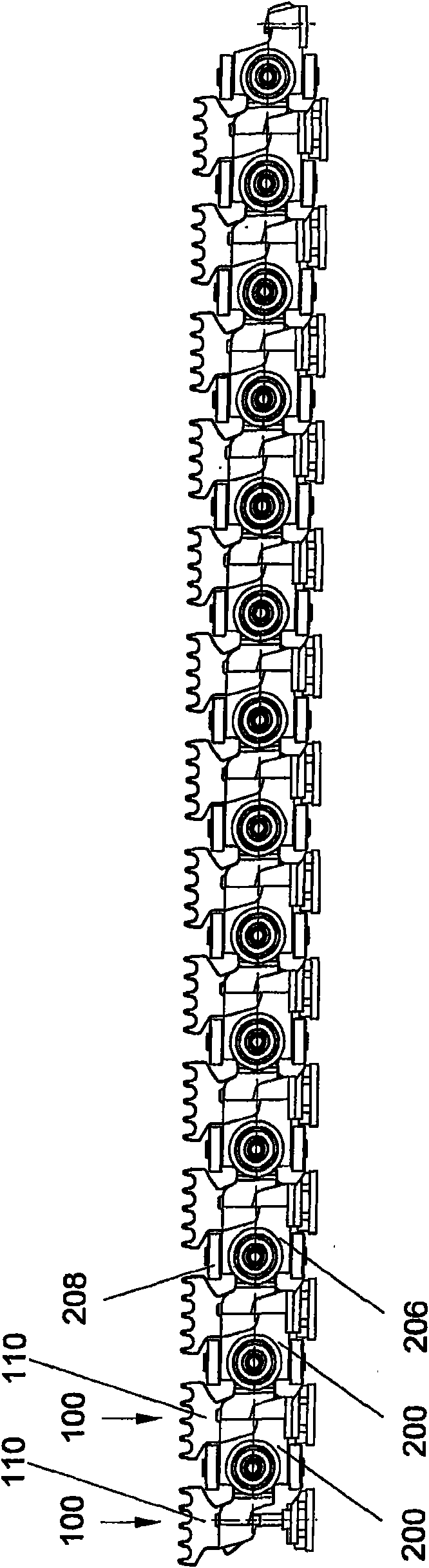

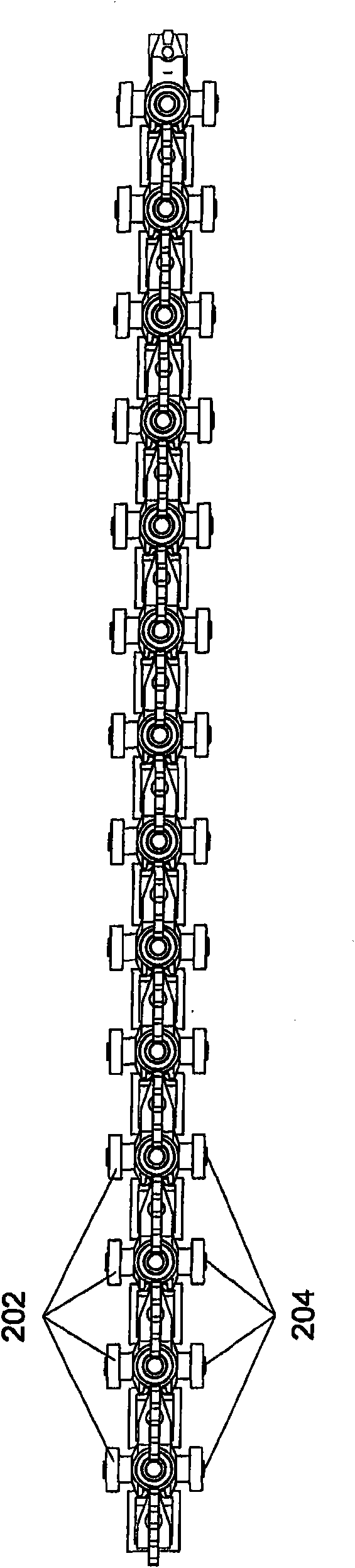

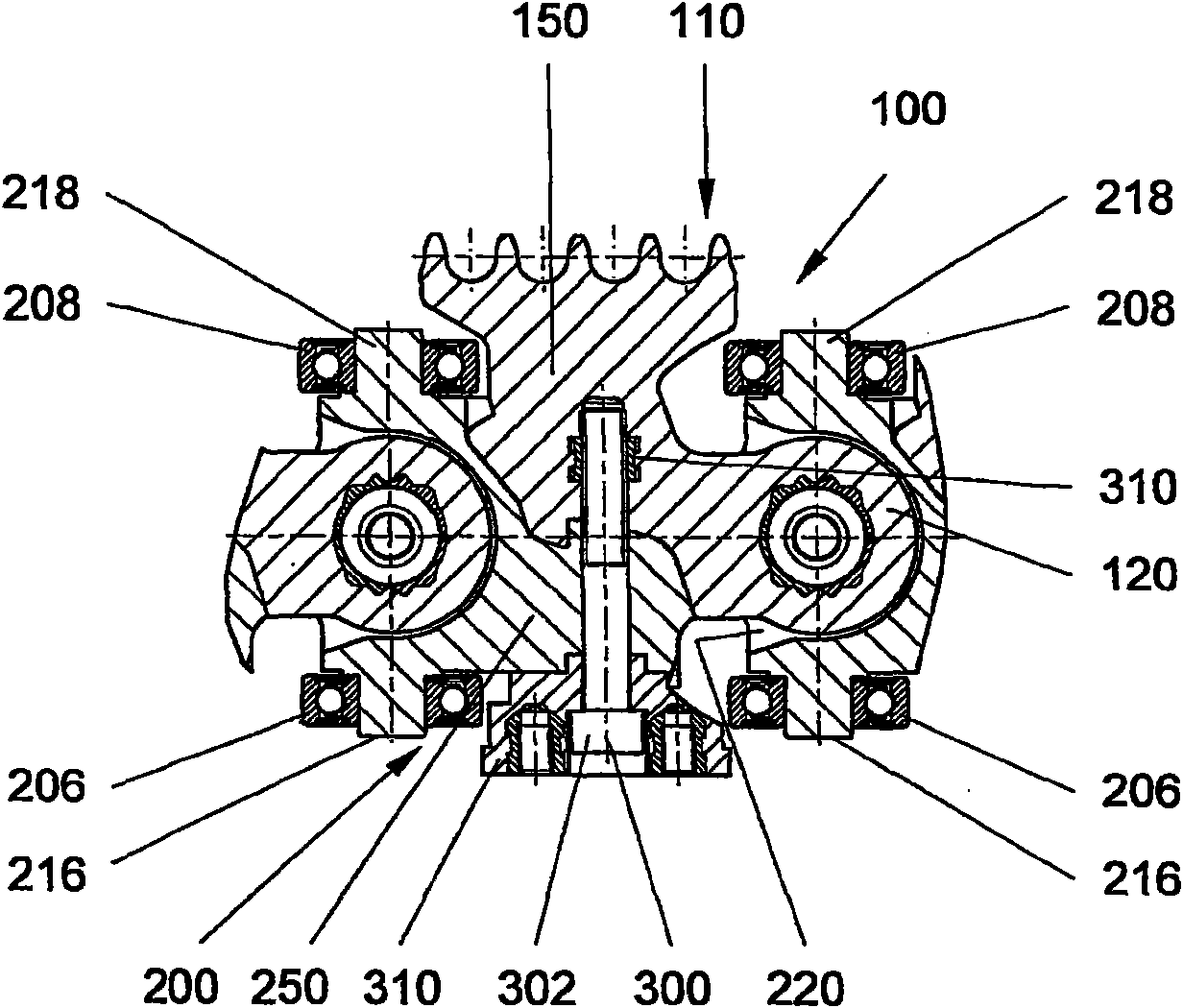

[0041] The conveyor chain shown in the drawing comprises a functional part in the form of a first chain link 100 and a second chain link 200 . Each first link 100 has a comb-shaped coupling zone 110 for coupling the conveyor chain to the drive chain 530 (see Figure 11 )superior. Each second chain link 200 has a total of four guide rollers 202, 204, 206, 208, wherein the guide rollers 206 and 208 are mounted rotatably about a first common roller axis and the guide rollers 202, 204 are rotatably arranged about a second common roller axis. The shaft is rotationally positioned. The first and second rollers extend perpendicular to each other and are arranged in one plane. Each first chain link 100 is arranged between two second chain links 200 . In this case, each first chain link 100 is rigidly connected on the one hand to a second chain link 200 to form a functional device and on the other hand is connected to another second chain link 200 to form a joint arrangement.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com