Fuel supply device

A fuel supply device and fuel technology, which are applied to liquid fuel feeders, charging systems, combustion engines, etc., can solve the problems of fuel supply failure and engine restart, and achieve the effect of reducing fuel supply failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

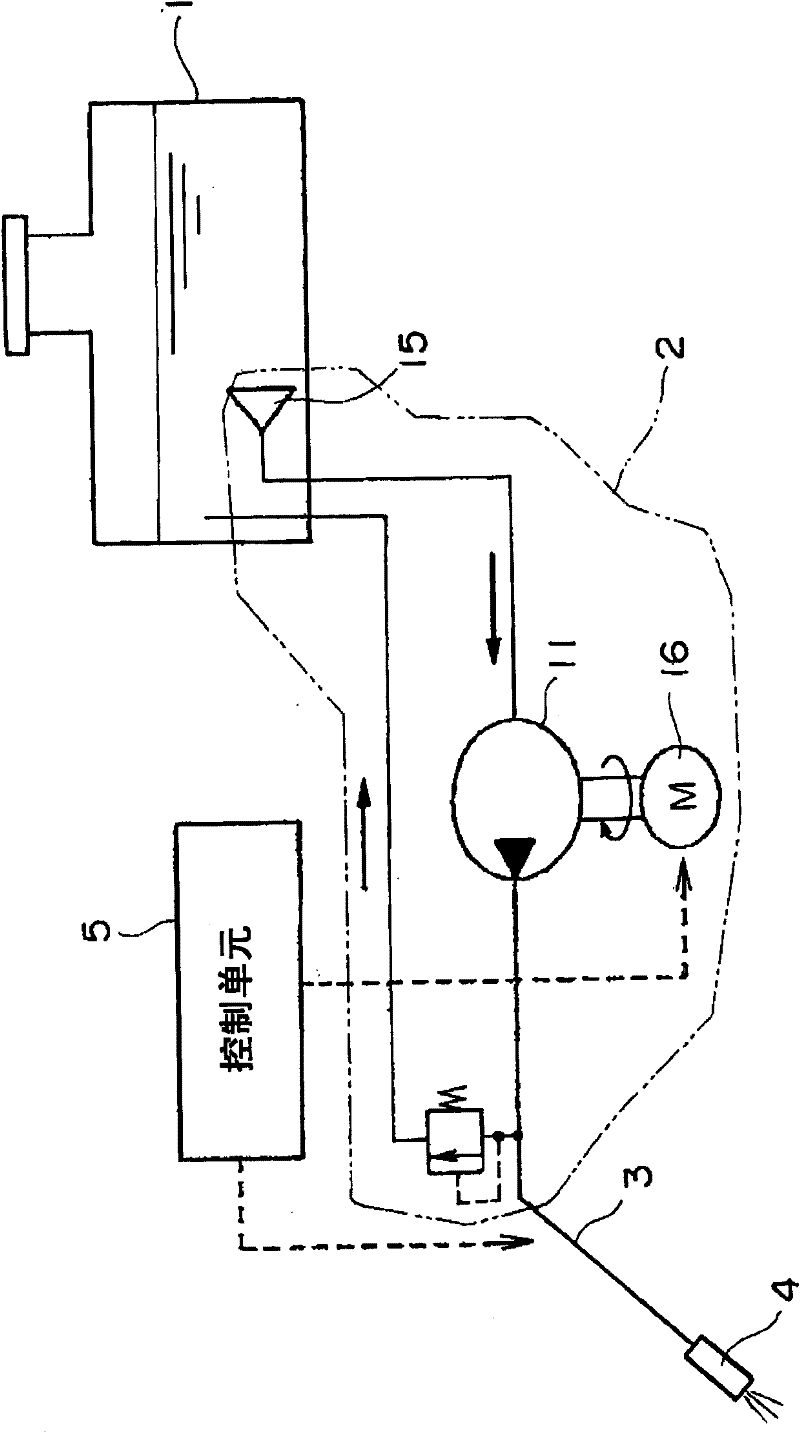

[0019] figure 1 It is a configuration diagram showing a fuel supply system incorporating the fuel supply device according to Embodiment 1 of the present invention.

[0020] The fuel supply system includes: a fuel tank 1; a fuel supply device 2 according to Embodiment 1 of the present invention, which is directly installed on the bottom surface of the above-mentioned fuel tank 1; A fuel supply device 2 is connected to inject fuel supplied from the fuel supply device 2 into a fuel chamber (not shown); and a control unit 5 that controls the fuel supply from the fuel supply device 2 to the fuel injection valve 4 and the fuel Injection time of injection valve 4.

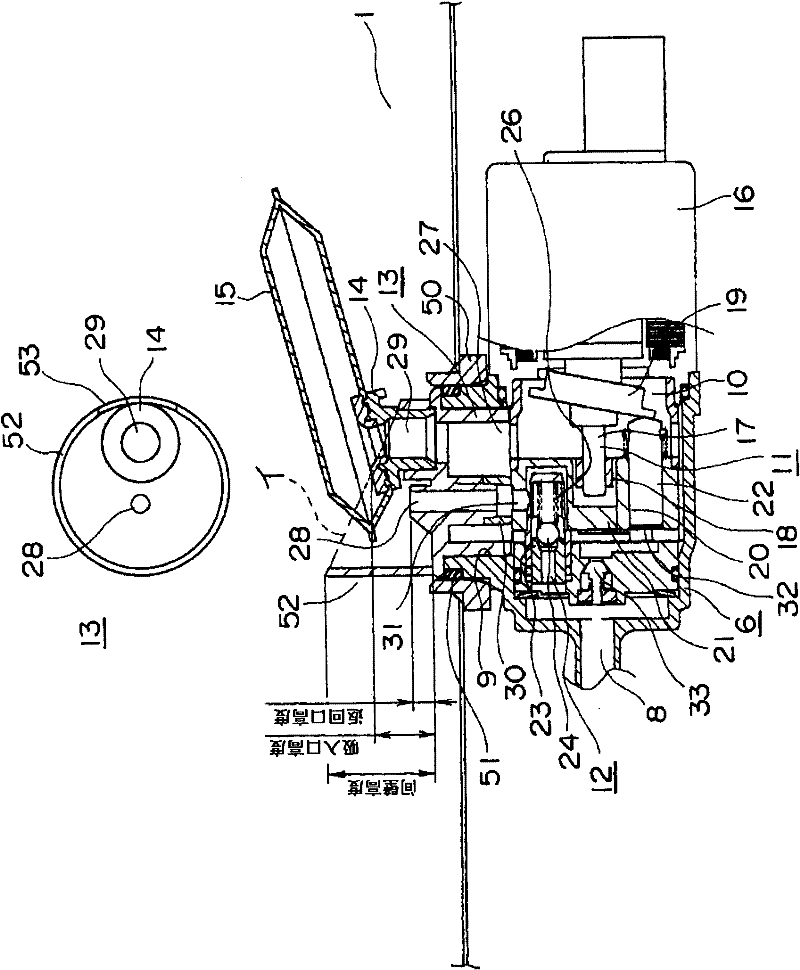

[0021] figure 2 It is a partially cutaway sectional view of the fuel supply device 2 . In addition, a plan view of the adapter 13 is also shown in the figure.

[0022] The fuel supply device 2 includes: a casing 6 having a high-pressure fuel passage 8 and an opening 9 on the side of the fuel tank 1; The fuel is pres...

Embodiment approach 2

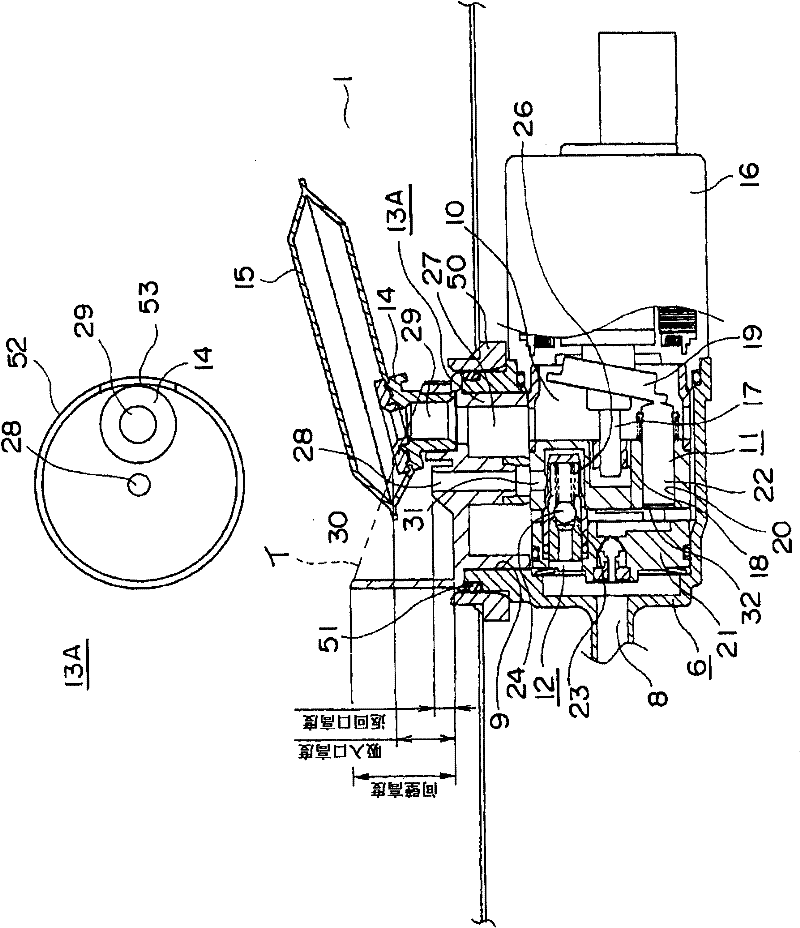

[0053] image 3 is a partial sectional view of the fuel supply device 2 . In addition, a plan view of the adapter 13A is also shown in the figure.

[0054] In the adapter 13A of the present embodiment, the return port of the return passage 28 is formed at the center of the circular partition wall 52 as viewed in the axial direction.

[0055] Other configurations are the same as those of the fuel supply device in Embodiment 1.

[0056] In this fuel supply device 2, since the return port of the return passage 28 is formed at the center of the adapter 13A, the circumferential direction of the adapter 13A can be changed around the return port without changing the installation position of the fuel supply device 2 on the fuel tank 1 . The position, that is, the position of the filter 15 connected to the suction passage 27 through the mounting member 14 can be changed.

[0057] Furthermore, since the filter 15 can be arranged arbitrarily in the circumferential direction with respe...

Embodiment approach 3

[0060] Figure 4 is a partial sectional view of the fuel supply device 2 . In addition, a plan view of the adapter 13B is also shown in the figure.

[0061] In this embodiment, the main body of the adapter 13B fitted into the opening 9 of the housing 6 is made of hard resin, and only the partition wall 52A is made of an elastic member such as rubber.

[0062] Other configurations are the same as those of the fuel supply device in Embodiment 1.

[0063] When the fuel supply device 2 is attached to the device attachment hole of the fuel tank 1, the filter 15 is attached to the adapter 13B via the attachment member 14 before attachment.

[0064] At this time, when the filter 15 faces upward, the partition wall of the adapter will not become an obstacle to installation, but if the filter 15 is substantially parallel to the bottom surface of the fuel tank 1, the partition wall will become an obstacle to installation.

[0065] In contrast, in this embodiment, since the partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com