Family of cutting inserts, milling cutting tool, and cutting insert

一种切削刀片、铣削刀具的技术,应用在铣削切削刀片、铣刀、成型刀等方向,能够解决径向切削力震颤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

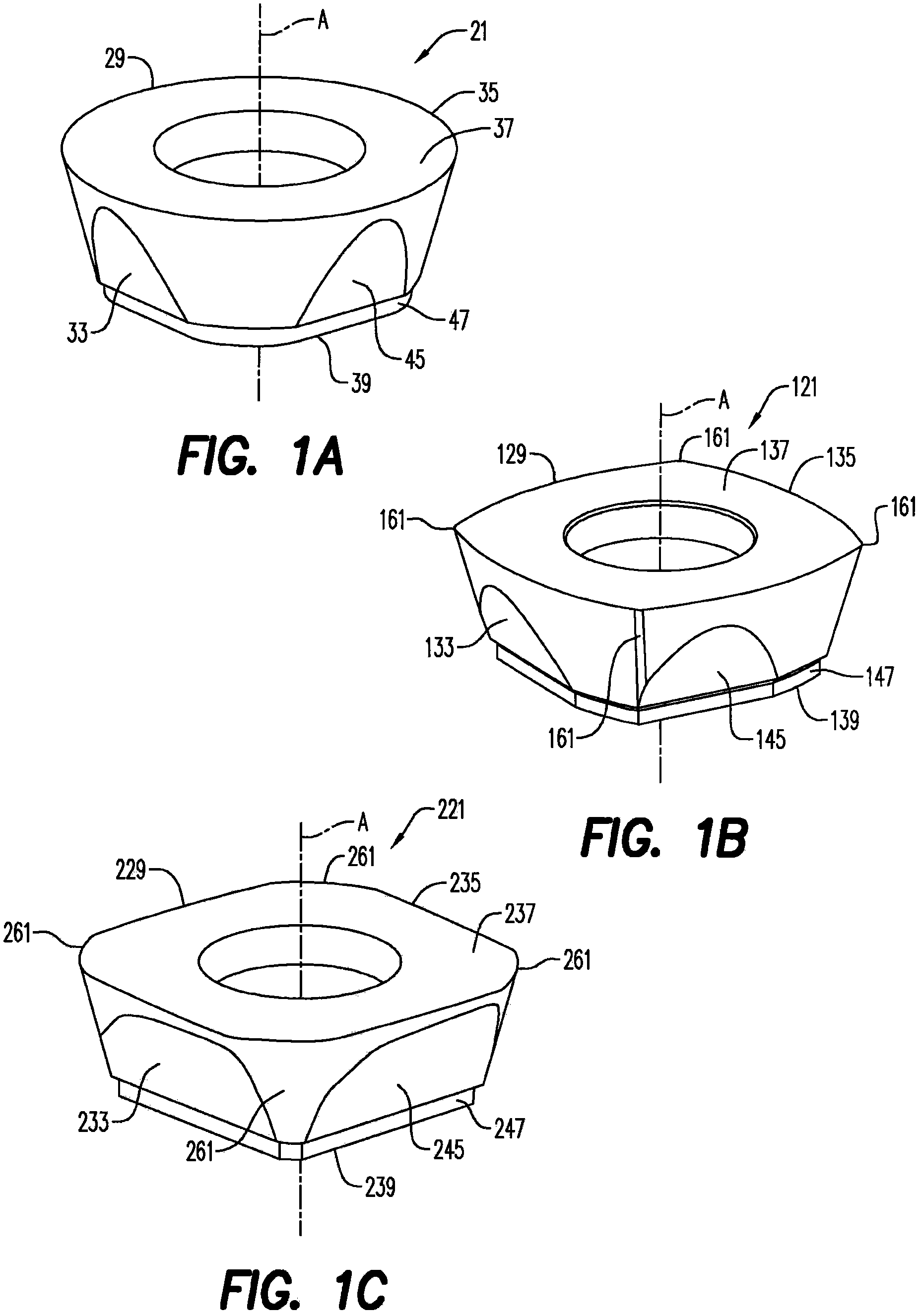

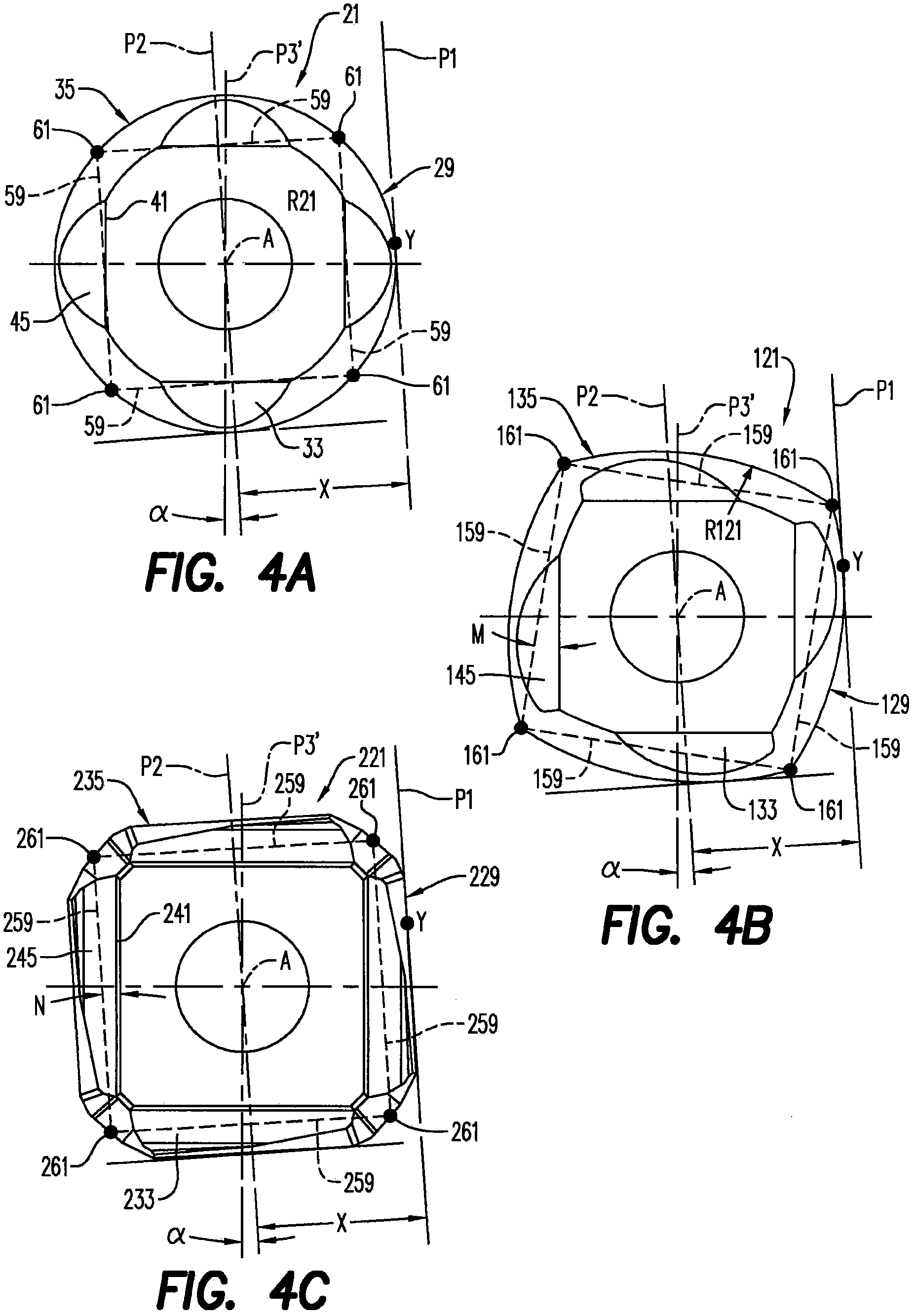

[0021] The different inserts 21, 121, 221 of the cutting insert set are shown in Figures 1A-1C. Each blade 21 , 121 , 221 has a different geometry, for example, but not necessarily, a cutting edge that is differently shaped when viewed in top view. For purposes of illustration, blade 21 has a circular shape when viewed in plan view; The diameter of the circle and the corners between the cutting edges are rounded; the blade 221 has a generally quadrilateral (with four sides) shape when viewed in plan view, the radius of the cutting edge is larger than the diameter of the circle defined in the blade , and have multiple (three) chamfers between the cutting edges. Differences in geometry may involve other features of the insert, either as an alternative or in addition to the cutting edge, such as the presence or absence of chip breakers, flat or curved wiper surfaces, etc.

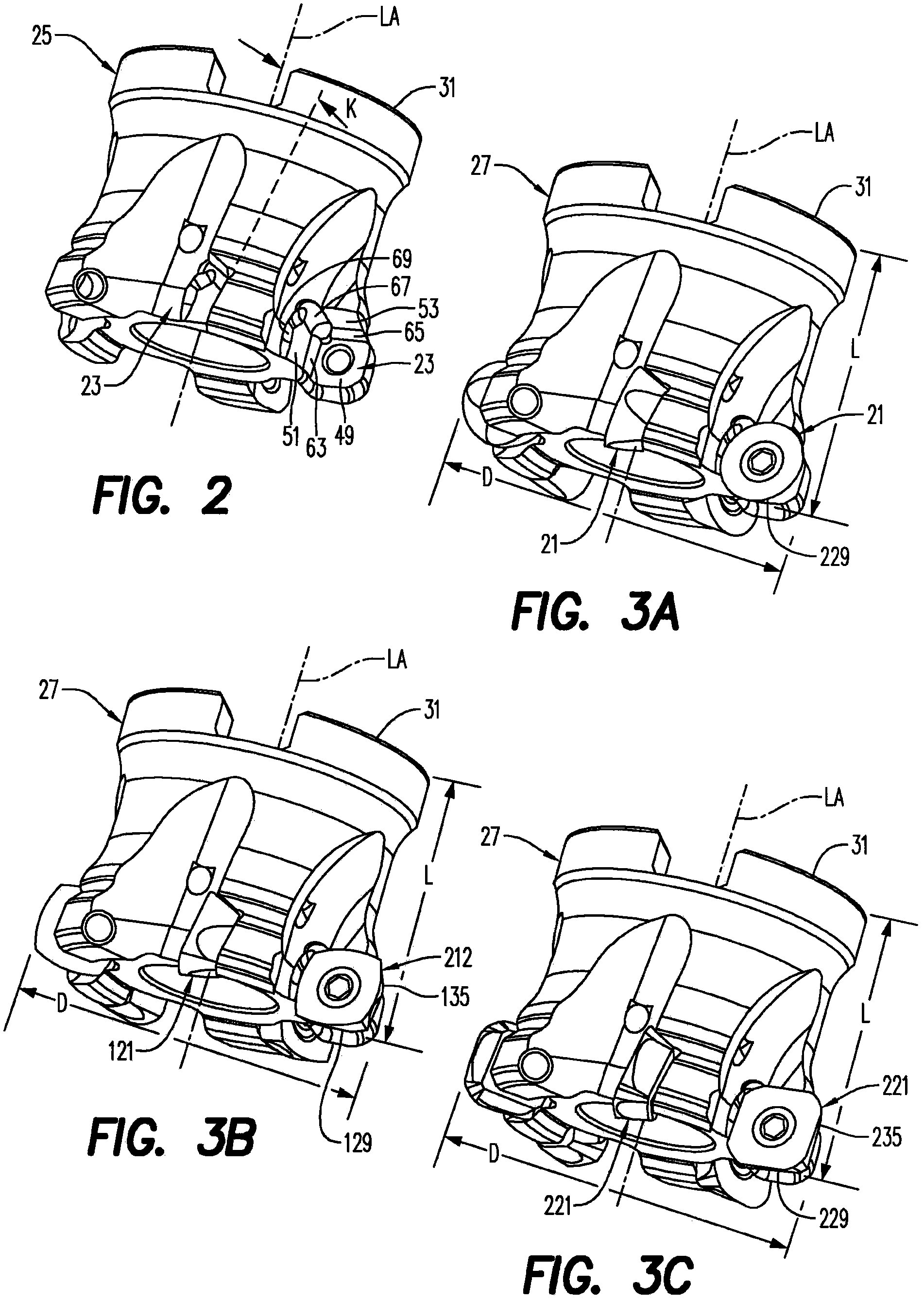

[0022] Each of the plurality of different inserts 21, 121, 221 is configured to be adapted to be mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com