Anti-sediment backwashing back pressure valve

A backwash and back pressure valve technology, applied in valve details, safety valves, balance valves, etc., can solve the problems that the back pressure valve cannot control the pre-valve pressure, cannot control the pre-valve pressure, and the back pressure valve cannot meet the requirements. The effect of eliminating resistance, long service life and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

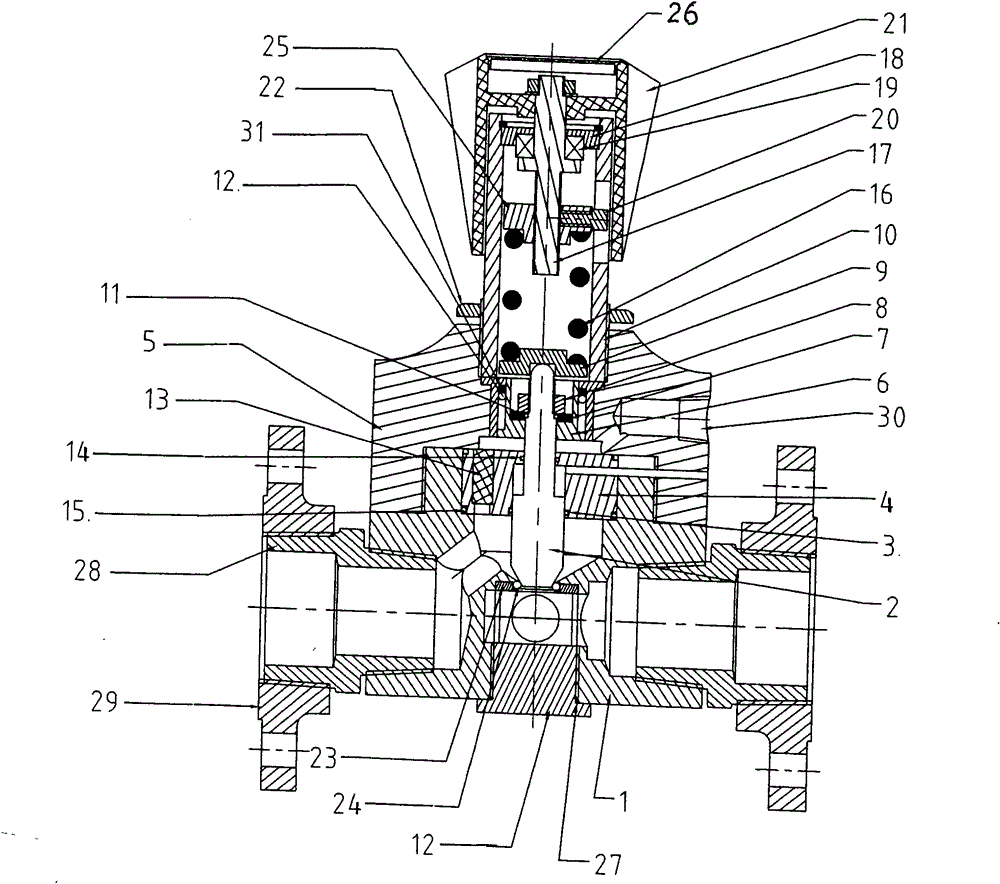

[0014] An anti-sediment type backwashing back pressure valve, comprising: an upper valve body 5, a lower valve body 1, a pressure regulating device, a sealing device, a piston 6, a valve column 2, a sealing seat 24, an adapter 28 and a flange 29 . The cavity composed of upper valve body 5, lower valve body 1, valve column guide sleeve 4, piston 6, and piston guide sleeve 32 is the piston cylinder cavity. Below the piston cylinder cavity, a valve column guide with high-precision filter element 13 is set The sleeve 4 is provided with an exhaust through hole at the upper end of the valve column guide sleeve 4, and is provided with a sweeping ring 3 at the lower part of the inner hole of the valve column guide sleeve 4. The spool 2 is in the shape of an air needle, that is, a vertical hole of appropriate length is drilled from the end face of the spool, and a horizontal hole communicating with the hard hole is drilled from the side of the spool. A backwash passage 30 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com