Shaft coupling device in pump body

A technology of coupling device and pump shaft, which is applied to components, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problems of high maintenance cost, troublesome maintenance, waste of motor shafts, etc., and achieve low maintenance cost , Time-saving and labor-saving disassembly, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

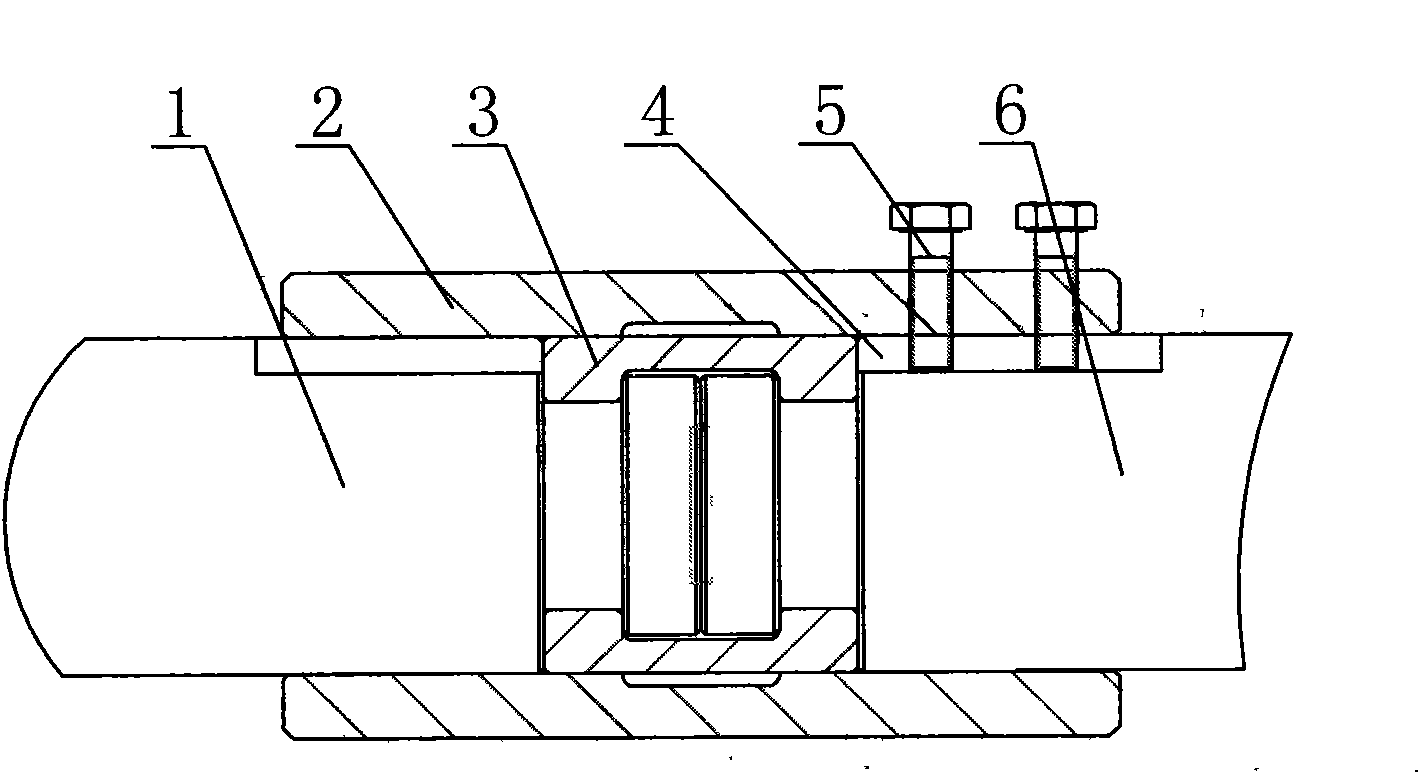

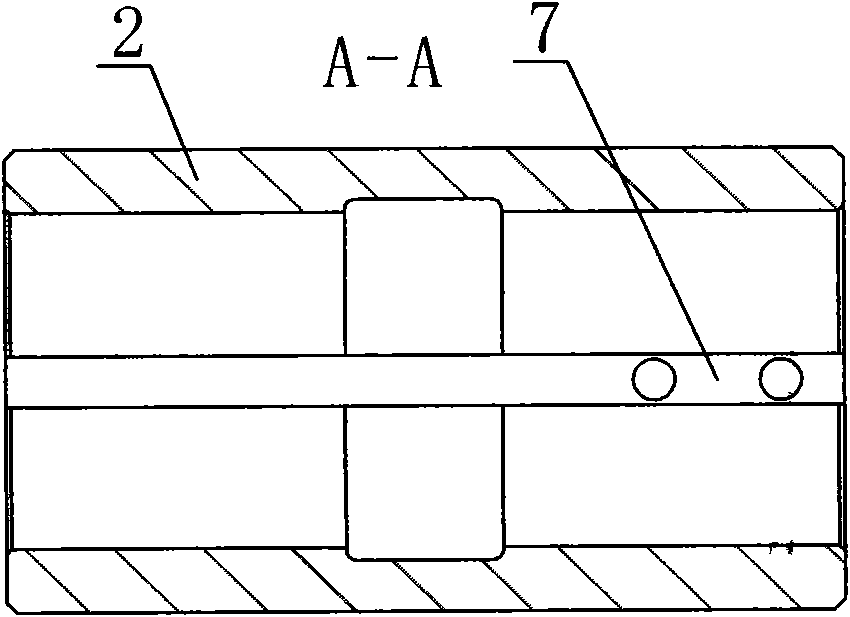

[0010] As shown in the figure, the internal coupling device of the pump body, the front end of the pump shaft 1 and the motor shaft 6 is provided with a card slot, and the card slot is provided with a connecting ferrule 3, and the outer diameter of the connecting ferrule 3, pump shaft 1 and motor shaft 6 There is a fixed sleeve 2, and the fixed sleeve 2 is provided with a keyway corresponding to the pump shaft 1 and the motor shaft 6, from figure 2 , image 3 It can be seen from the figure that the fixed sleeve 2 is provided with a keyway 7 . There is a fixed key 4 in the keyway, the pump shaft 1 and the motor shaft 6 are positioned through the connecting ferrule 3, and then the torque is transmitted between the motor shaft 6 and the pump shaft 1 through the connection between the fixed key 4 and the fixed sleeve 2, which avoids the two shafts passing through the thread In the case of locking due to connection, the coupling is easy to disassemble during maintenance, avoiding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com