Variable control method for one-stage variable oil pump of engine and one-stage variable oil pump of engine

A variable control, oil pump technology, applied in the pressure lubrication of the lubricating pump, controlling the pressure of the lubricant, etc., can solve the problems of high cost, high operating energy consumption, complex structure of the secondary variable oil pump, etc., to achieve cost savings, The effect of suppressing contact shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

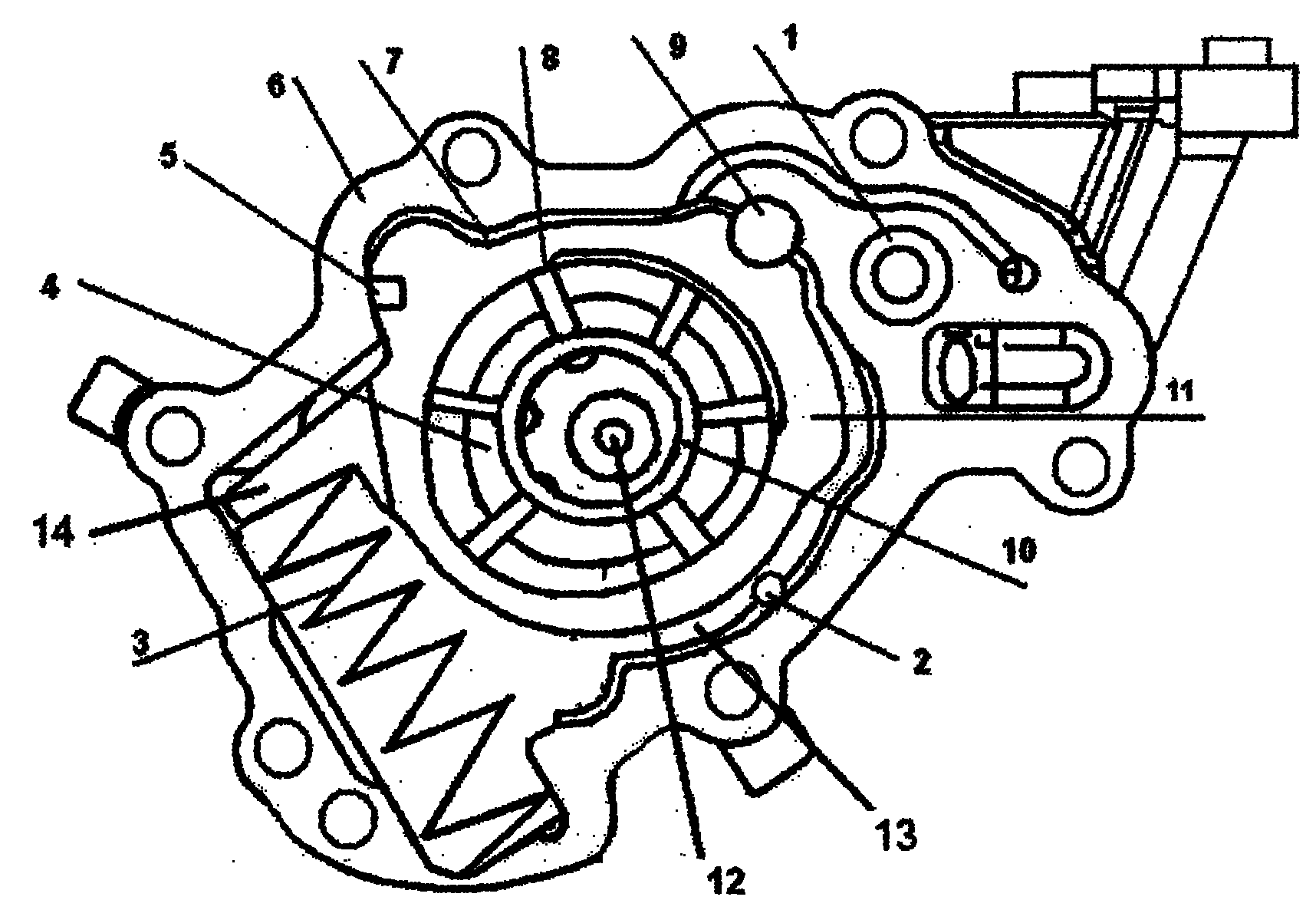

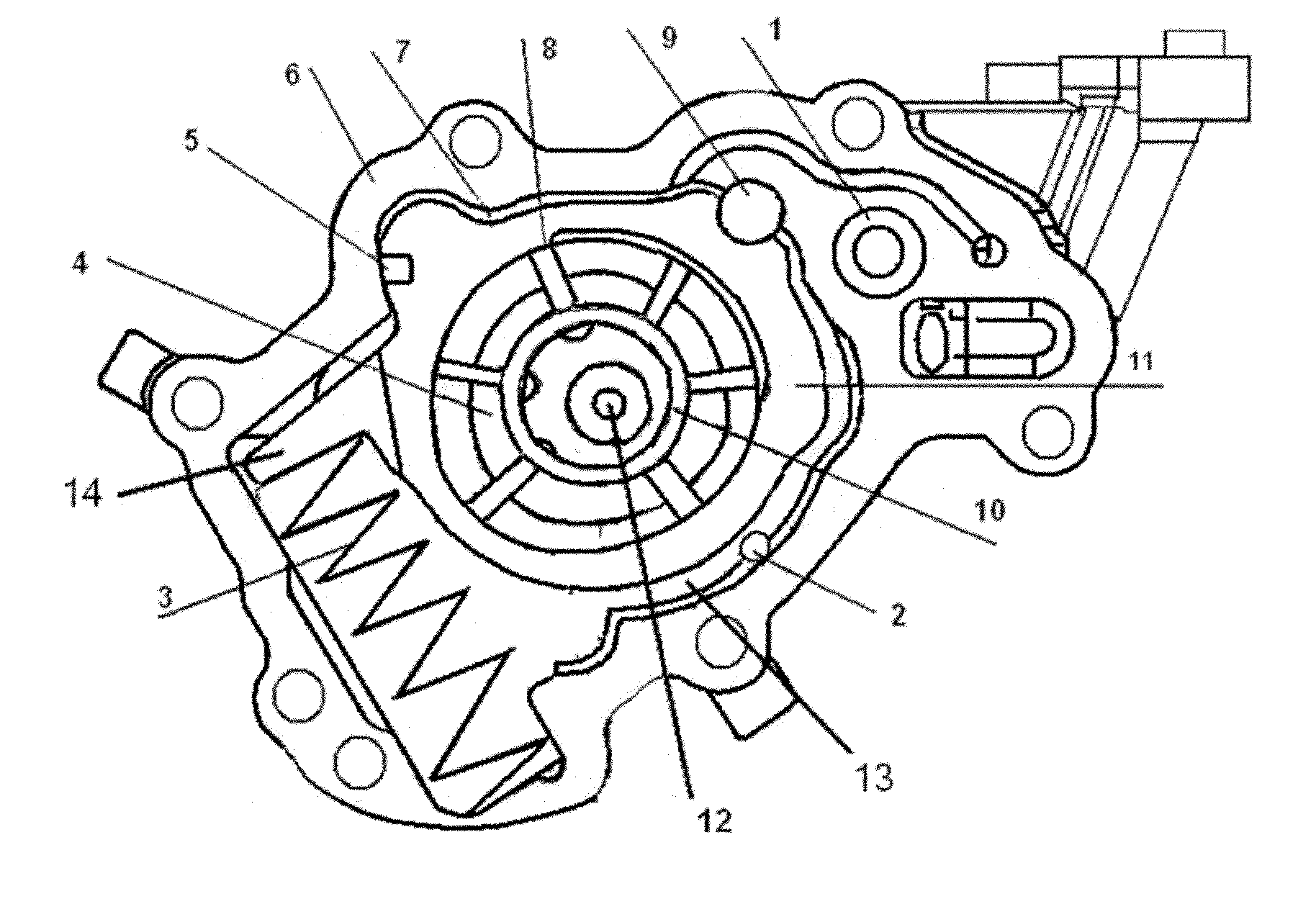

[0027] Such as figure 1 As shown, it is a one-stage variable vane oil pump, which includes a housing 6, a cavity is provided in the housing 6, a rotating shaft 12 passes through the housing 6, a rotor 4 is connected to the rotating shaft 12, and a radial shaft is connected to the rotor 4. The movable blade 8 is also provided with an eccentric blade support ring 10 in the cavity of the housing 6, and the variable slider ring 11 is hingedly connected with the variable slider ring 11 through the pin shaft 9 in the cavity of the housing 1, and the variable slider ring 11 is connected with the housing. A sealing device 5 is provided between the cavities. The variable slider ring 11 divides the cavity of the housing into a feedback pressure oil chamber 7 and an oil return chamber 13 . One side of the housing is provided with a variable spring 3, and the variable slider ring 11 is provided with a variable spring compression flange 14; between the variable spring compression flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com