Floor keel

A keel and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of easy loosening, difficult handling, time-consuming and labor-intensive, etc., and achieves good firmness, convenient operation, and small wood loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

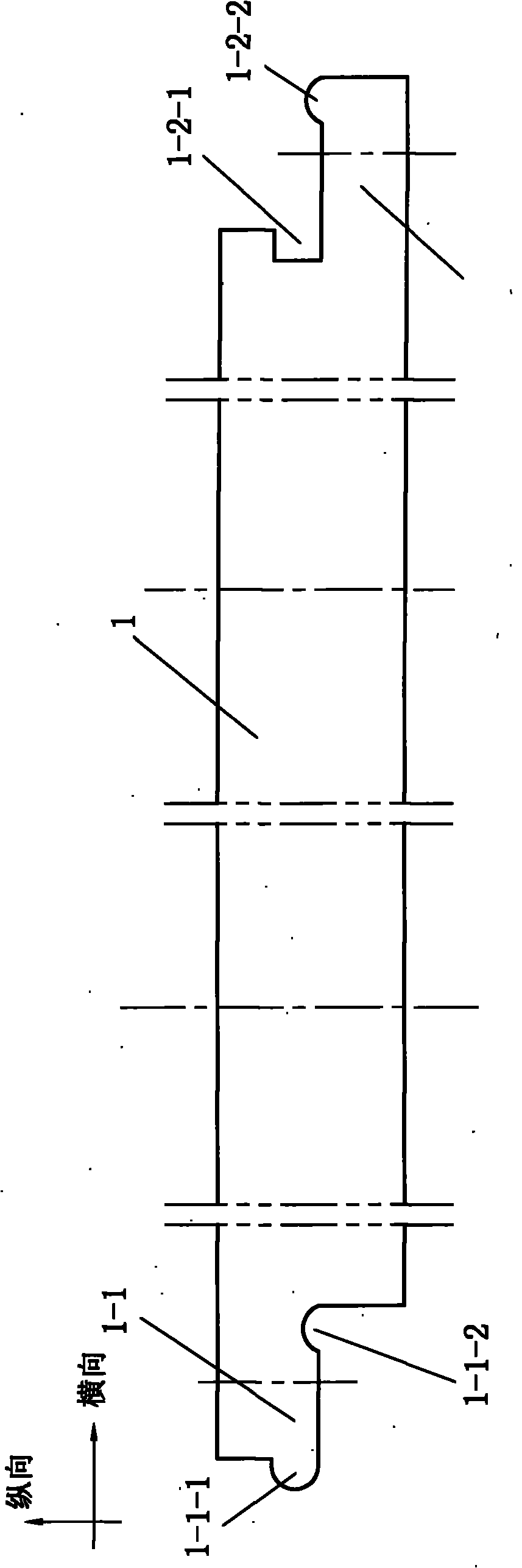

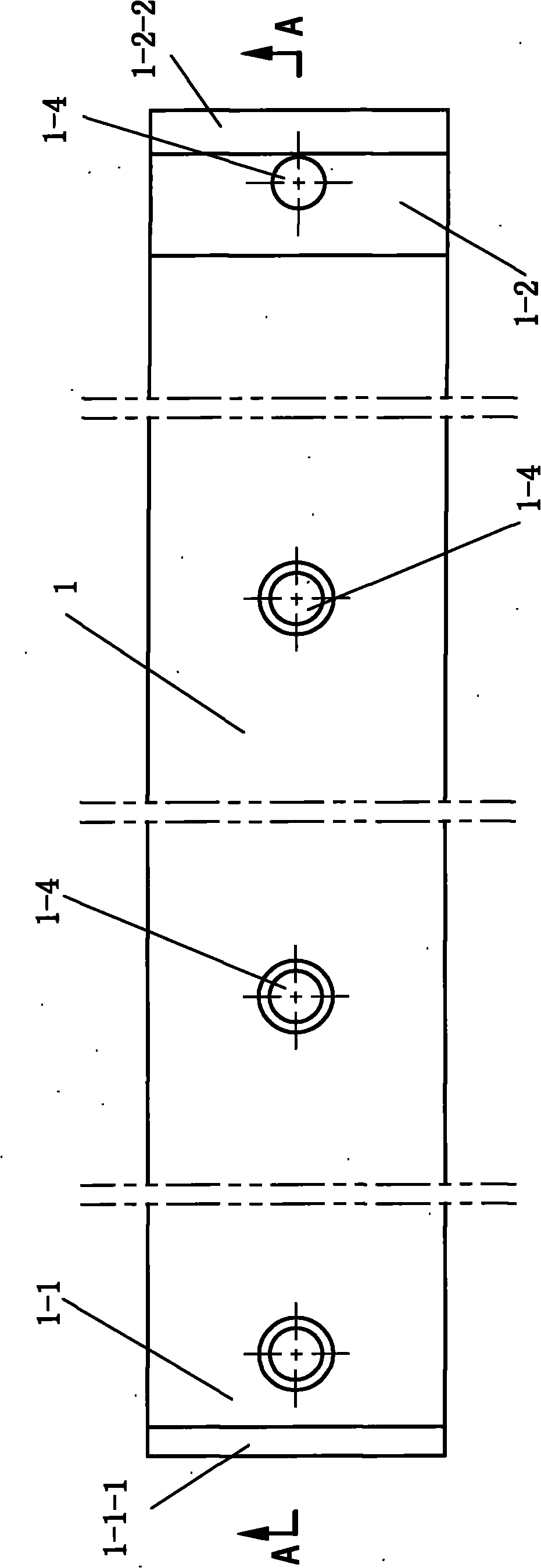

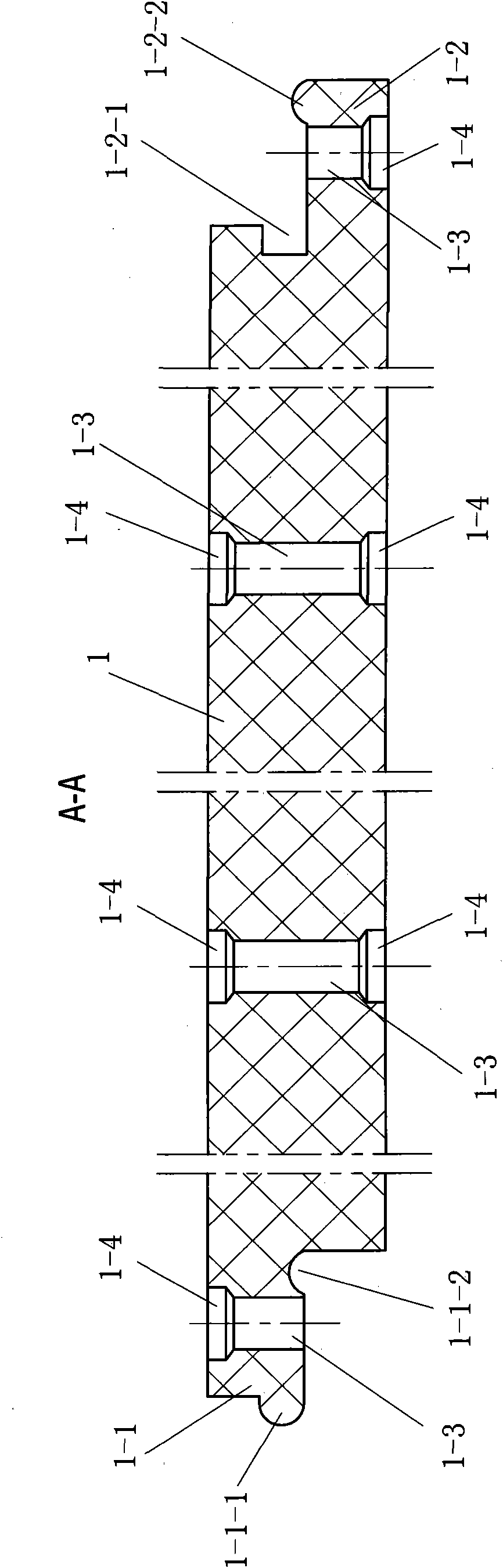

[0025] Such as figure 1 , 2 , 3, 4, 5, and 6, a floor keel, comprising a strip keel body 1 with a rectangular cross section, one end of the keel body 1 has an upper lock head 1-1, and the other end has a lower lock head 1 -2, two adjacent keel bodies 1 can be fastened and connected with the lower lock head 1-2 of the other keel body 1 through the upper lock head 1-1 of one of the keel body 1; the upper lock head 1 The sum of -1 and the longitudinal thickness of the lower lock head 1-2 is equal to the longitudinal thickness of the keel body 1.

[0026] Such as figure 1 , 3 , 4, 5, and 6, in order to ensure that two adjacent keel bodies 1 are fastened together without gaps and firm, the upper locking head 1-1 of the keel body 1 has a transverse protrusion 1-1-1 and The longitudinal notch 1-1-2, the lower lock head 1-2 of the keel body 2 has a transverse notch 1-2-1 and a longitudinal protrusion 1-2-2; the transverse protrusion of the upper lock head 1-1 1-1-1 is fastened wi...

Embodiment 2

[0032] Such as Figure 7 , 8 As shown in , 9 and 10, a floor keel includes a strip keel body 1 with a rectangular cross section, one end of the keel body 1 has an upper lock head 1-1, and the other end has a lower lock head 1-2. The two adjacent keel bodies 1 can be fastened and connected with the lower lock head 1-2 of the other keel body 1 through the upper lock head 1-1 of one of the keel body 1; The sum of the longitudinal thicknesses of the lock heads 1-2 is equal to the longitudinal thickness of the keel body 1 .

[0033] Such as Figure 7 , 9 , 10, in order to ensure the fastness of the adjacent keel main bodies, the upper lock head 1-1 of the keel body 1 has a longitudinal notch 1-1-3, and the lower lock head 1-2 of the keel body 1 It has a longitudinal protrusion 1-2-3; the longitudinal notch 1-1-3 of the upper lock head 1-1 is engaged with the longitudinal protrusion 1-2-3 of the lower lock head 1-2.

[0034] Such as Figure 7 , 9 , 10, in order to further imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com