Intelligent and digital single-roller color code tracking device

A tracking device and color labeling technology, applied in packaging, packaging protection, multiple packages, etc., can solve the problems that the deviation of the color label cannot be displayed quantitatively, the packer is difficult to grasp, and cannot be tracked, etc., to overcome the electromagnetic clutch-type color label. The defect of tracking device, the effect of color mark tracking is good, and the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. These embodiments should be understood as only for illustrating the present invention and not for limiting the protection scope of the present invention. After reading the contents described in the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent changes and modifications also fall within the scope defined by the claims of the present invention.

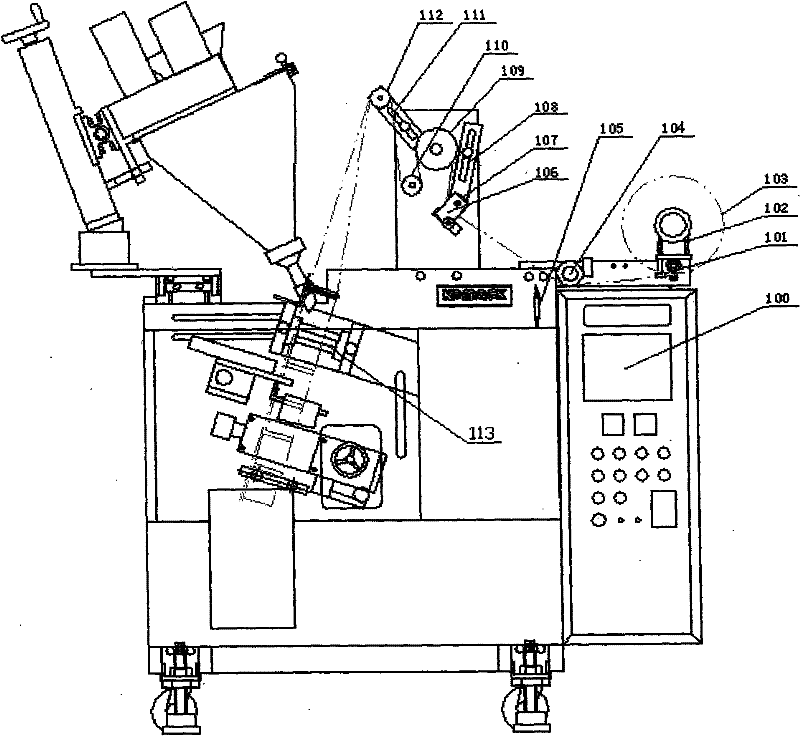

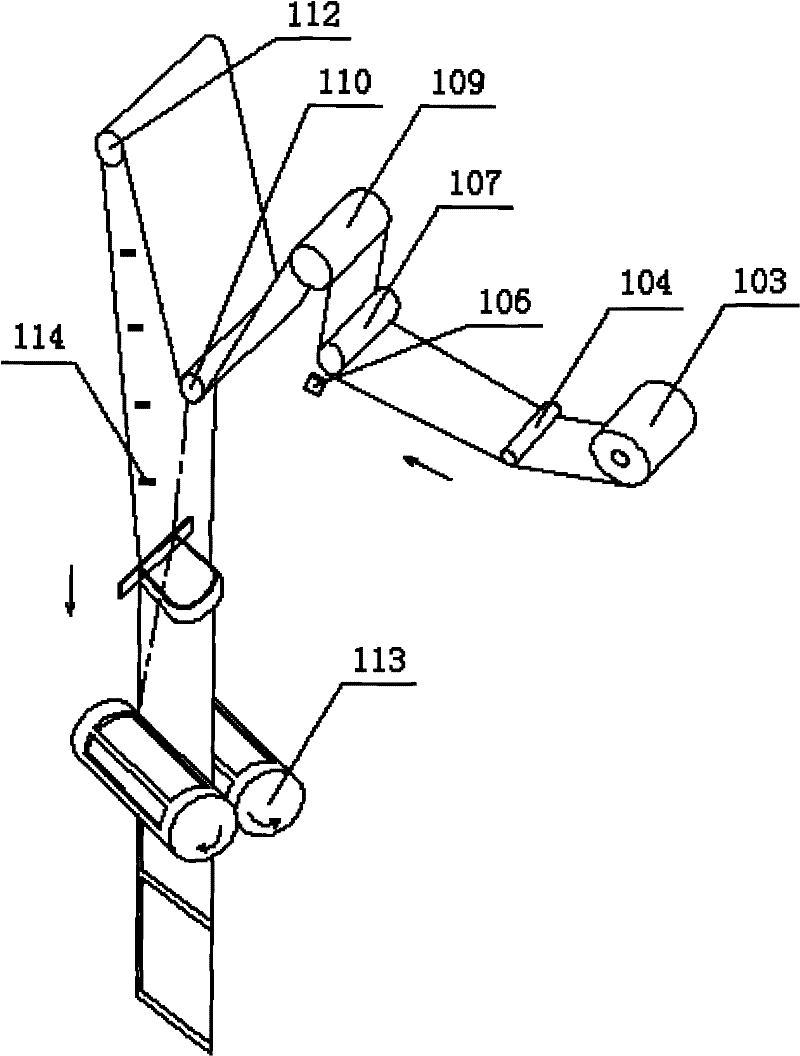

[0038] like Figure 1-2 As shown, in the single-roller intelligent digital color mark tracking device provided by a preferred embodiment of the present invention: the touch screen 100 is used to input data and display information; The adjustment control of the adjustment handle can change the damping of the round belt 102 to the film roll 103; the four film guide rollers 104, 107, 110 and 112 are used for the guide control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com