Method and device for generating foam in high-speed gas jet

A high-speed gas and high-speed airflow technology, which is applied in fire rescue and other fields, can solve the problems such as the inability to spray foam fire extinguishing agent, and achieve the effect of improving fire extinguishing efficiency and high foam formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

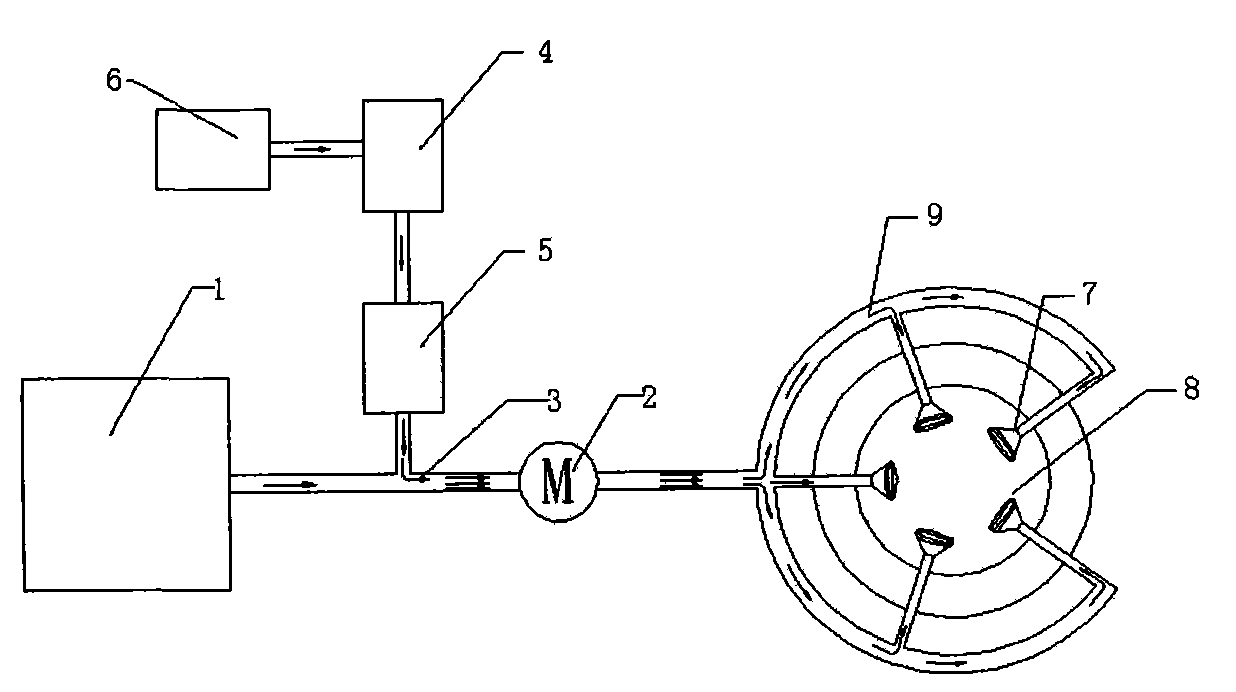

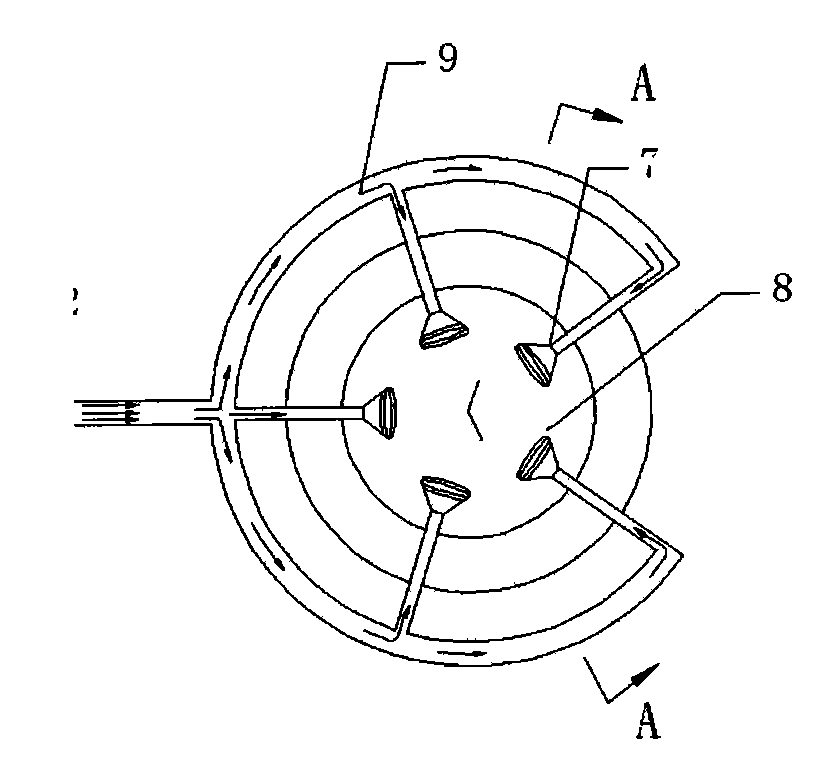

[0017] Example: Combined figure 1 and figure 2 , the water is input into the water pump 2 from the water tank 1 through the conveying pipe 3, and the inlet conveying pipe 3 of the water pump 2 is also connected with the proportional mixer 4; The mixer 4 and the electromagnetic switch 5 enter the inlet delivery pipeline 3 of the water pump 2, and the flow ratio of entering the delivery pipeline 3 to be mixed with water is set as 1%, 3%, or 1% when using an aqueous film-forming fire extinguishing agent. 6%; set it to 0.5%, 1%, 3% when using Class A foam fire extinguishing agent, and it can also be set according to needs.

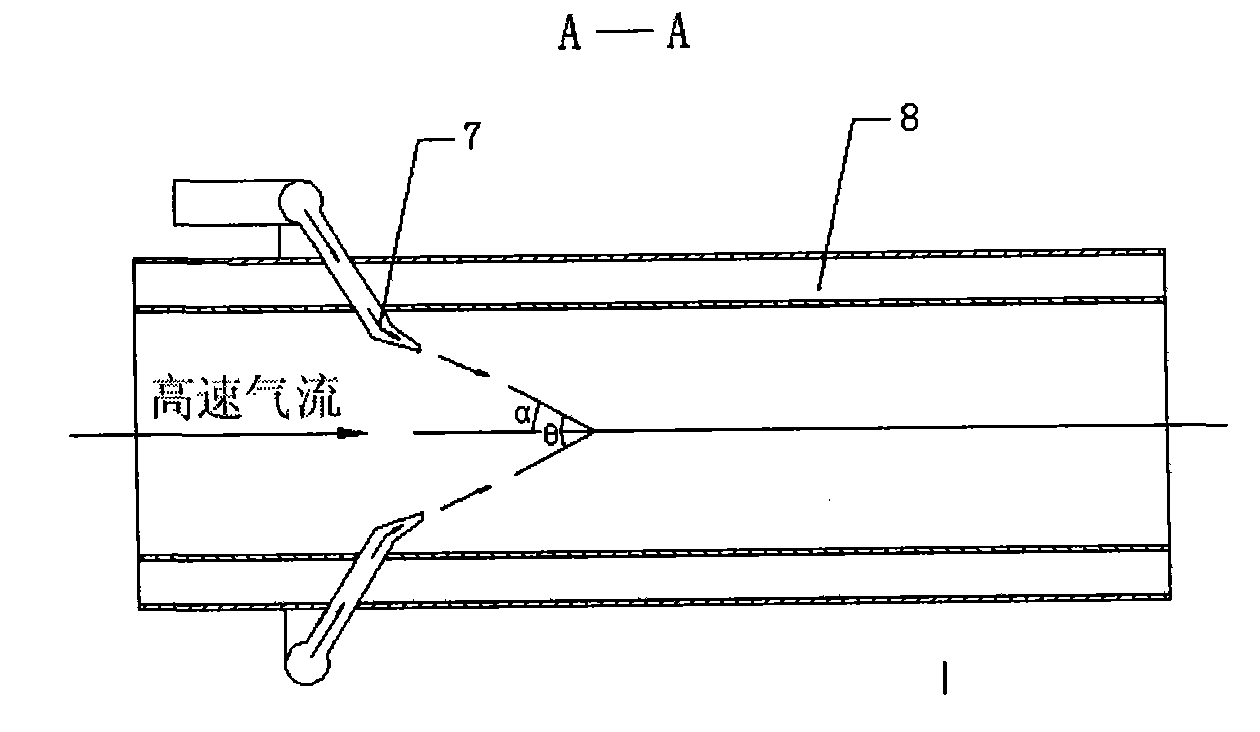

[0018] The water or the mixed liquid of water and foam fire extinguishing agent pressurized by the water pump 2 enters the liquid film nozzle 7 through the annular conveying pipeline 9, and is injected into the air-water energy exchange spray barrel 8 with a liquid film jet, and is connected with the vortex jet. When the high-speed air flow of the engine hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com