Method for recycling waste water of lead-acid storage battery

A lead-acid battery, waste water technology, applied in separation methods, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as waste of resources, and achieve the effects of reducing burden, improving water quality, and reducing lead ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

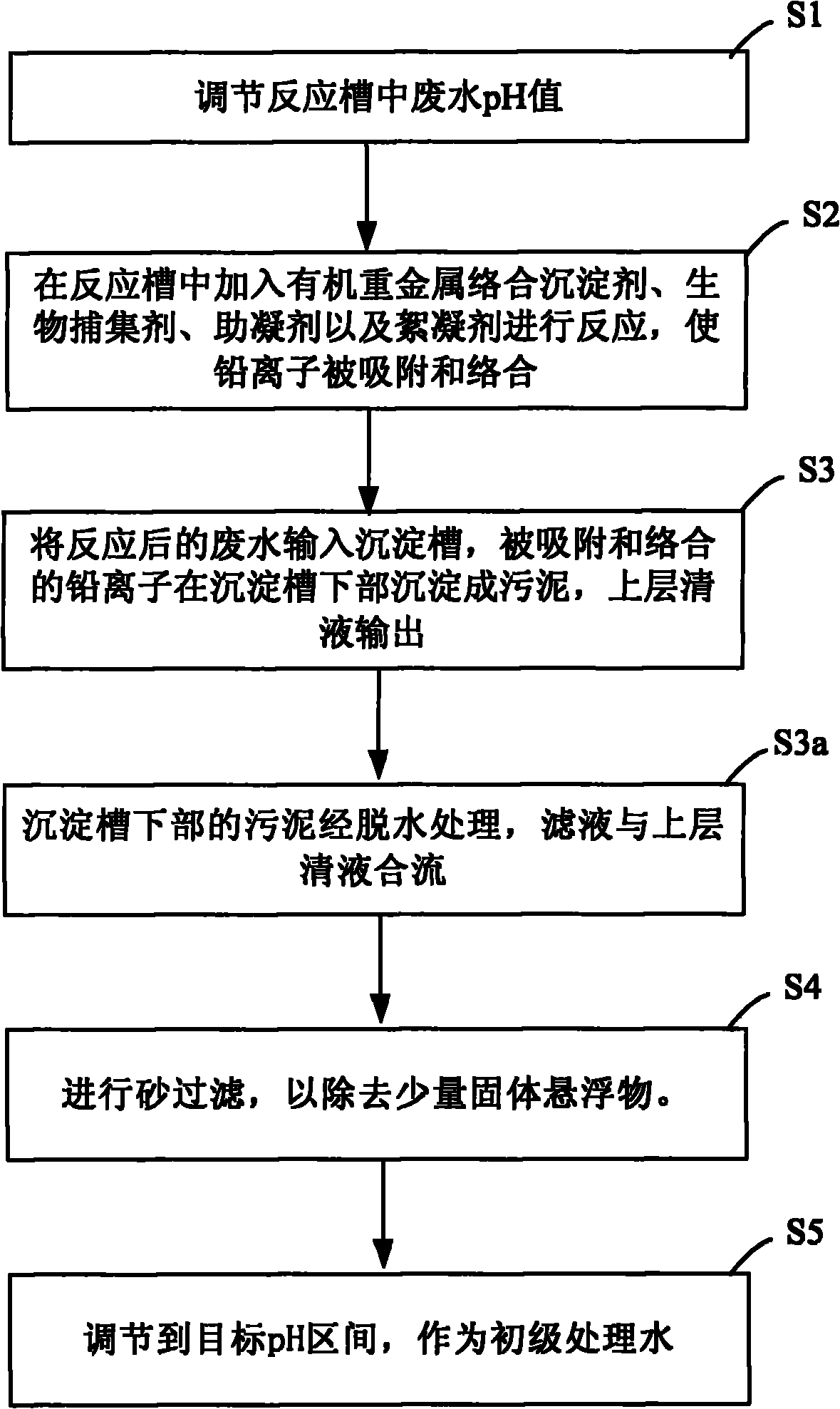

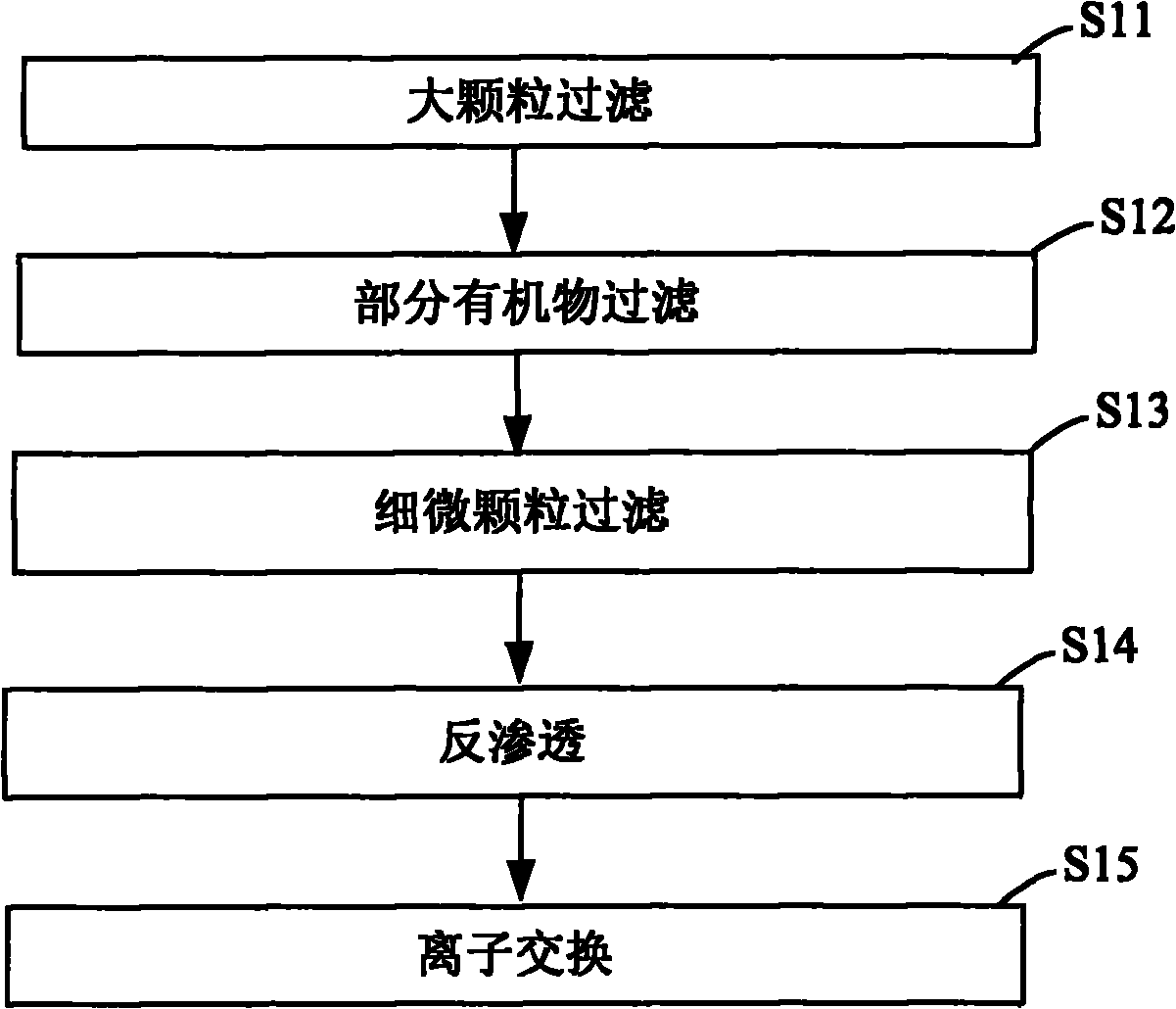

[0034] The method for recycling lead-acid battery wastewater according to the embodiment of the present invention includes two parts: a pre-treatment process and a post-treatment process. The pre-treatment process is mainly to enable the treated wastewater to be discharged or reused up to the standard, and the post-treatment process is mainly to perform advanced treatment to produce pure water that is directly used in production.

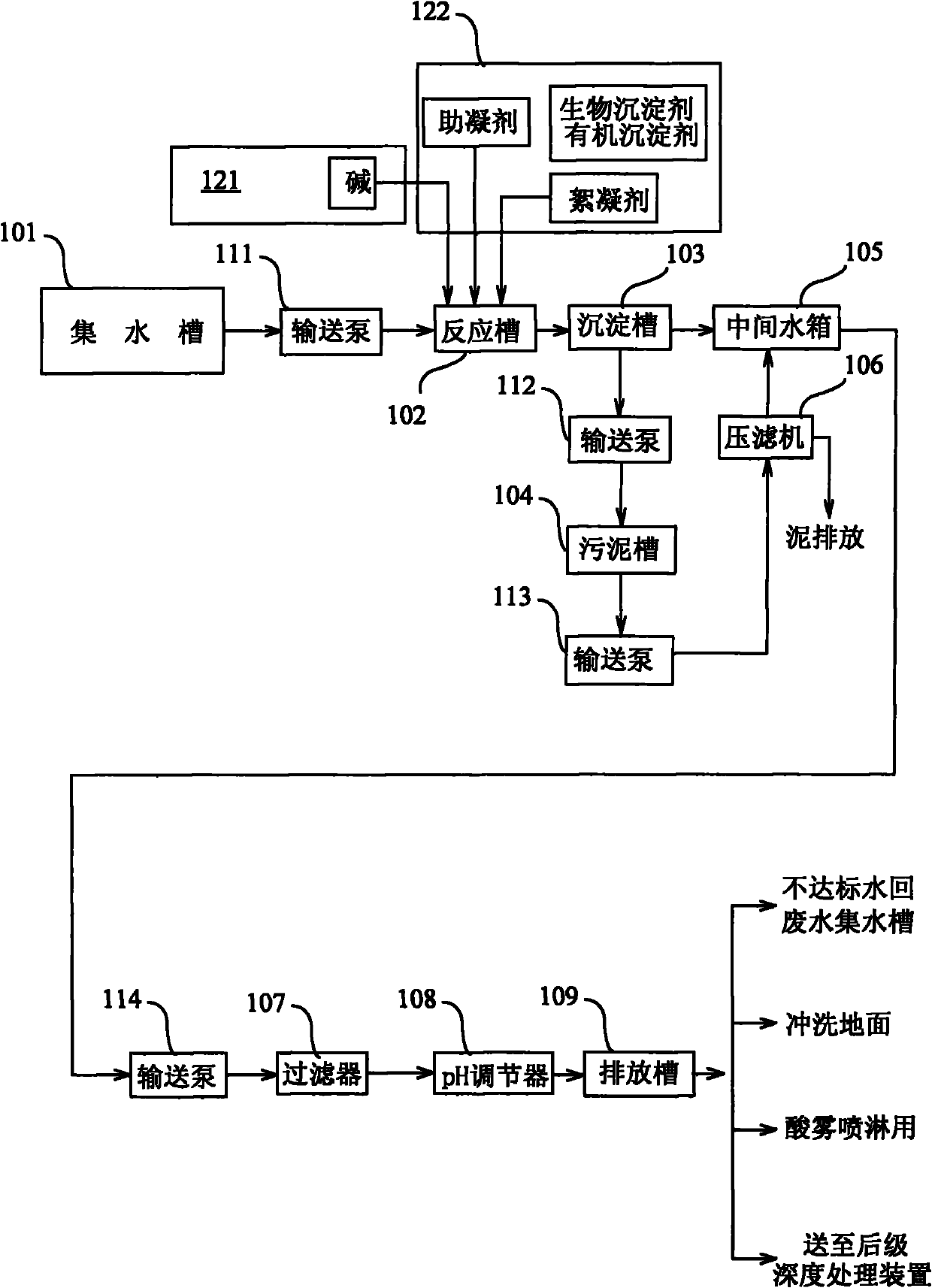

[0035] figure 1 It shows the pre-treatment process flow in the lead-acid battery wastewater reuse method according to an embodiment of the present invention. image 3 It shows the pre-processing equipment in the lead-acid battery wastewater recycling method according to an embodiment of the present invention. Refer below figure 1 and image 3 Shown describes the pre-treatment process.

[0036] refer to figure 1 As shown, the equipment 100 used in the pre-treatment process includes a water collection tank 101, a reaction tank 102, a sedimentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com