Method and system for controlling fuel pressure

A fuel supply system and fuel technology, applied in the direction of charging system, electrical control, engine control, etc., can solve problems such as multi-working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

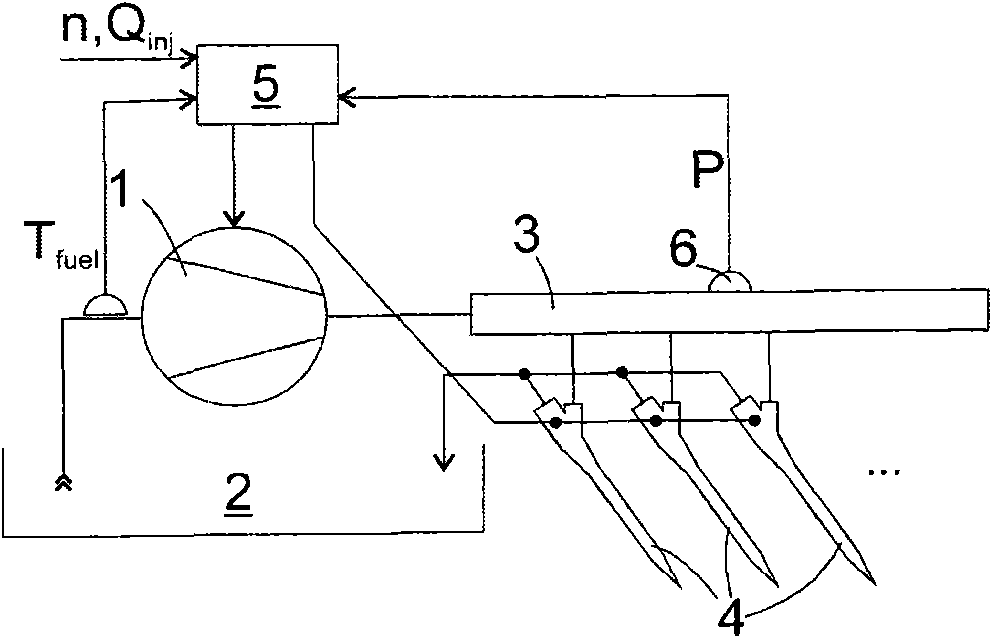

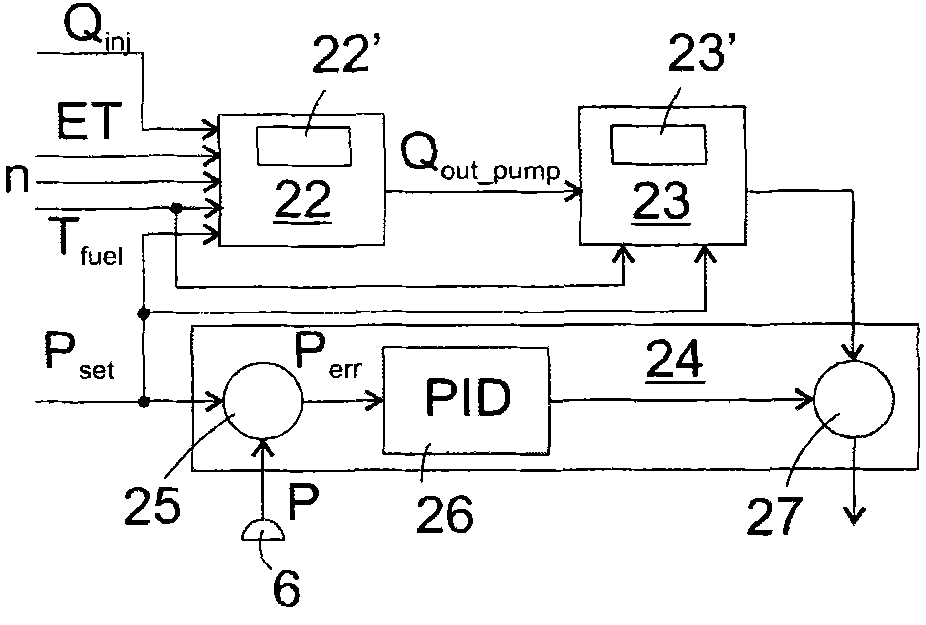

[0071] figure 1 It is a schematic outline of a fuel supply system of a diesel engine to which the present invention is applicable. A fuel pump 1, such as a gear pump or a pump having multiple pistons driven by the same rotating eccentric device, draws fuel from the tank 2 and supplies it to the rail 3 under high pressure. The rail 3 connects any number of injectors 4 to the rail to inject fuel from the rail into a cylinder (not shown) of the diesel engine. Based on rail pressure P and fuel temperature T detected by sensors 6 and 7 at rail 3 fuel , The rotational speed n of the diesel engine and the fuel injection quantity Q to be injected per cylinder per stroke inj (Set by a higher-level controller (not shown)), the electronic controller 5 controls the rotation speed of the pump 1 and the activation time of the ejector 4.

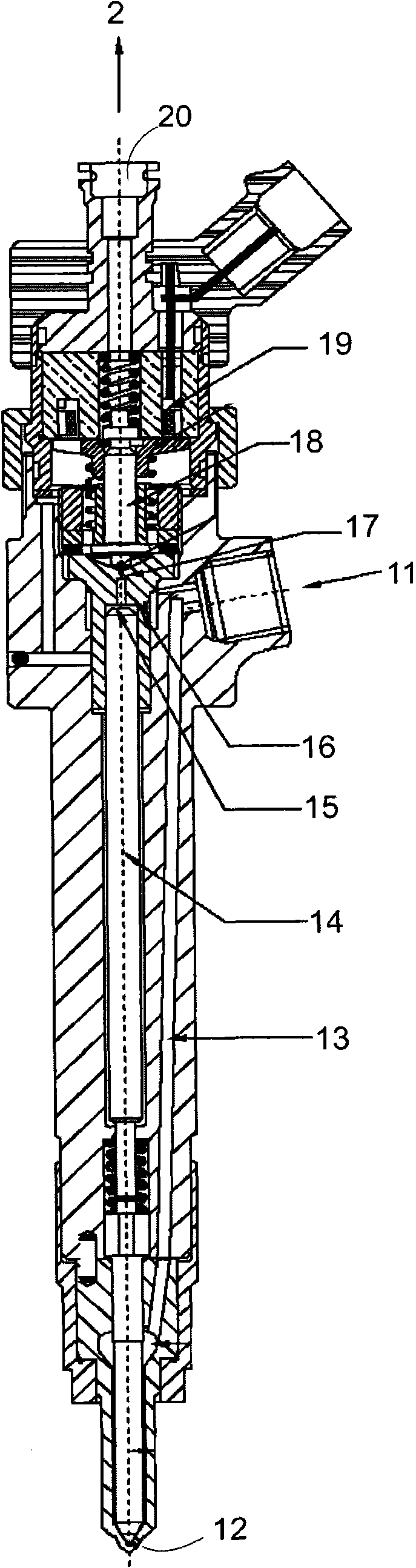

[0072] figure 2 It is a schematic longitudinal section of the ejector 4. The high-pressure fuel inlet 11 (which receives fuel from the rail 3) is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com