Chunk type strip winding equipment

A kind of equipment and strip technology, which is applied in the field of group type strip winding equipment, can solve the problems of container insulation tape packaging winding, translational sliding, and inconsistent winding layers, so as to improve the packaging quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments and drawings, but the protection scope of the present invention is not limited thereto.

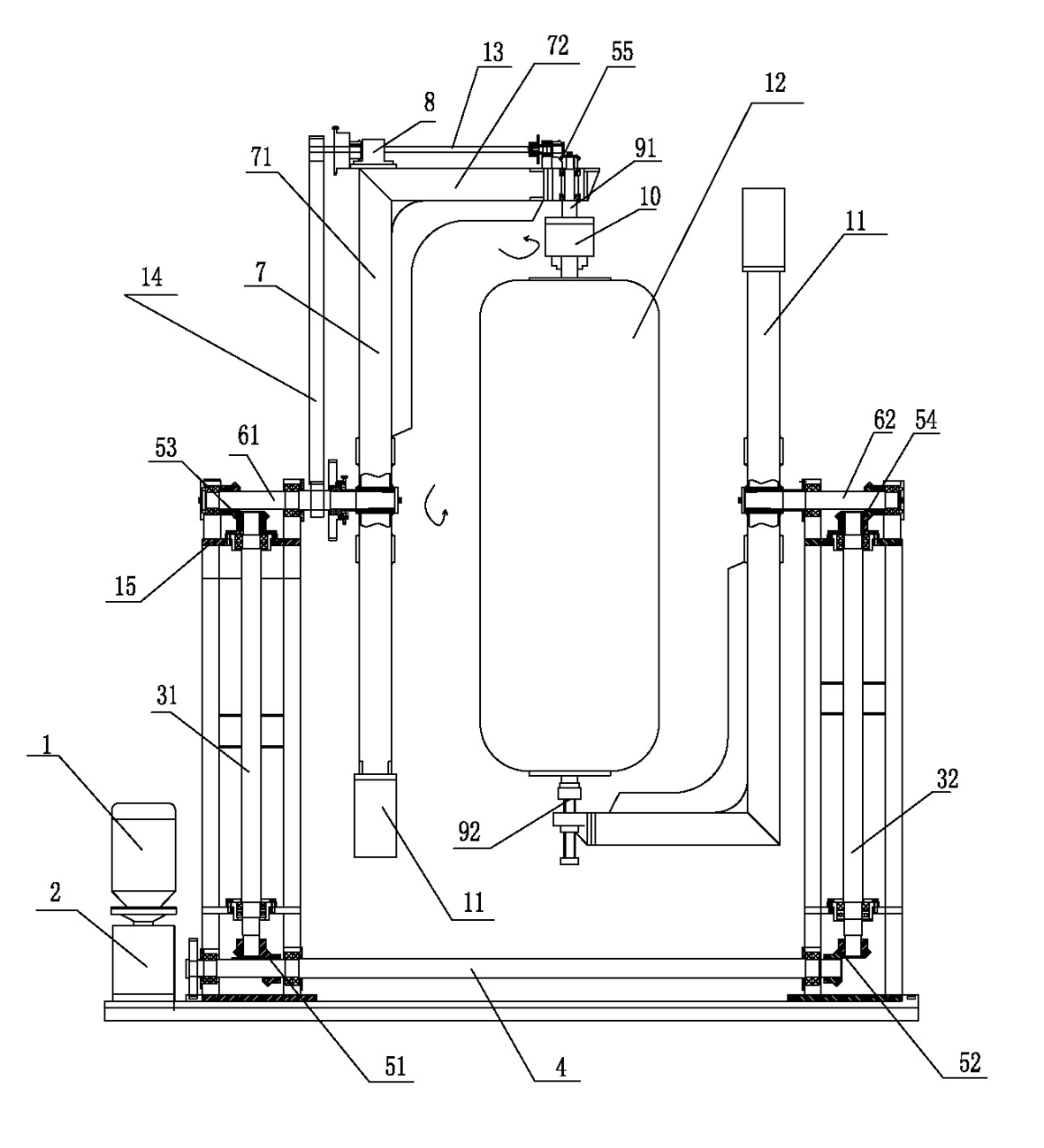

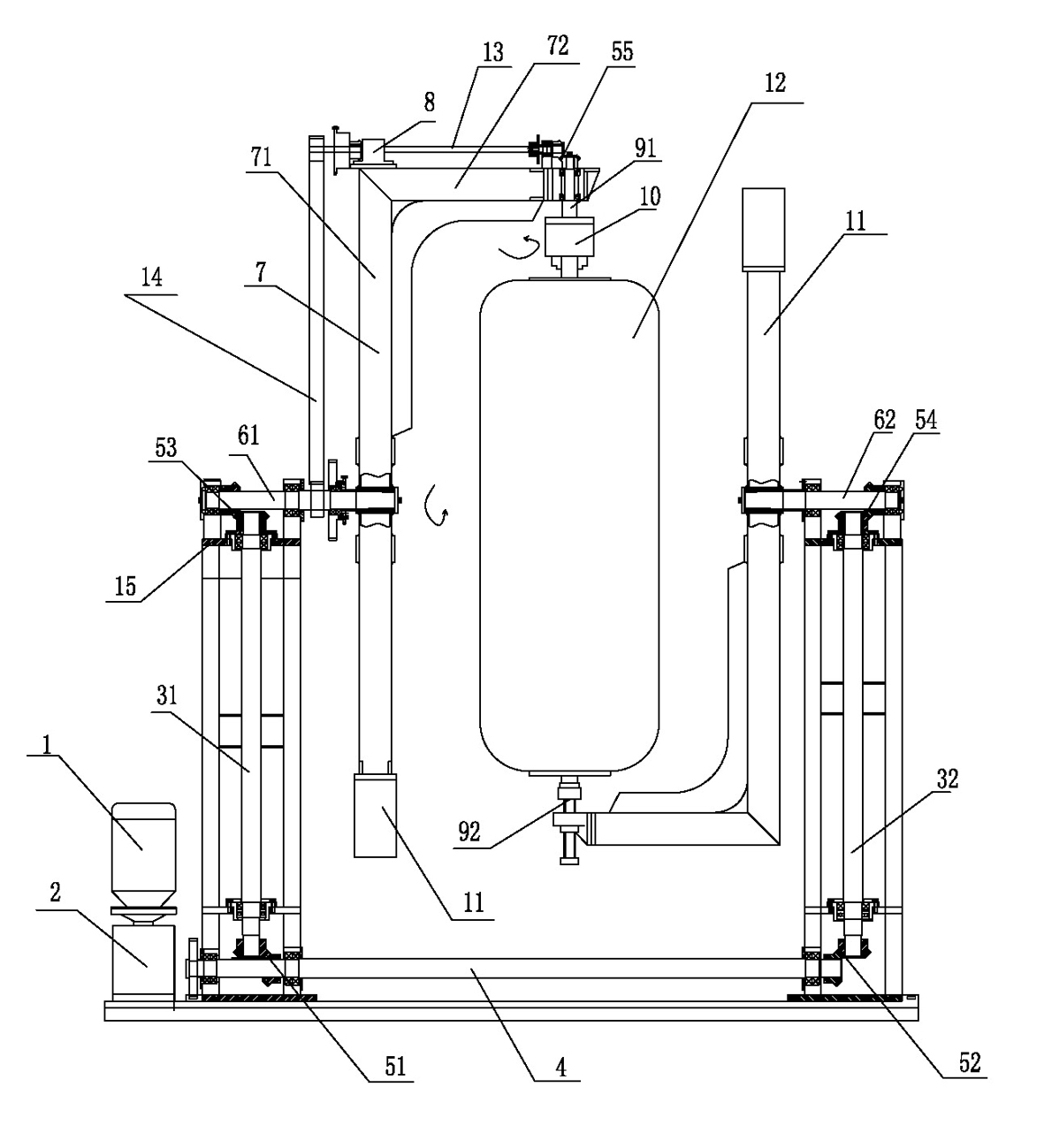

[0016] see figure 1 , a group type strip winding equipment, the equipment is composed of a motor 1, a transmission mechanism, a fixed bracket 15, a rotating bracket and a winding container 12, and the transmission mechanism includes two The horizontal rotation shafts 61, 62 on both sides of the winding container, and two longitudinal rotation shafts 91, 92 on the same line as the longitudinal centerline of the winding container and on both sides of the winding container, the horizontal rotation shafts 61, 62 are installed on the fixed bracket 15; the rotating bracket includes two rotating arms 7 that are symmetrical along the center of the winding container, the rotating arms 7 have a longitudinal section 71 and a transverse section 72, and the middle part of the longitudinal sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com