A Group Hole Drilling System

A technology of group hole and drilling equipment, applied in boring/drilling, drilling/drilling equipment, repairing and other directions, it can solve the problem of difficult control of hole and hole position tolerance, large number of holes in group anchor ring, high cost, etc. problems, to achieve the effect of reducing the number of mobile positioning, improving production efficiency, and reducing precision errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

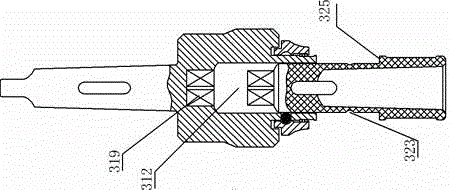

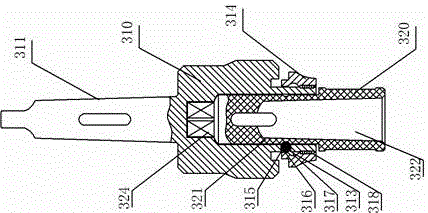

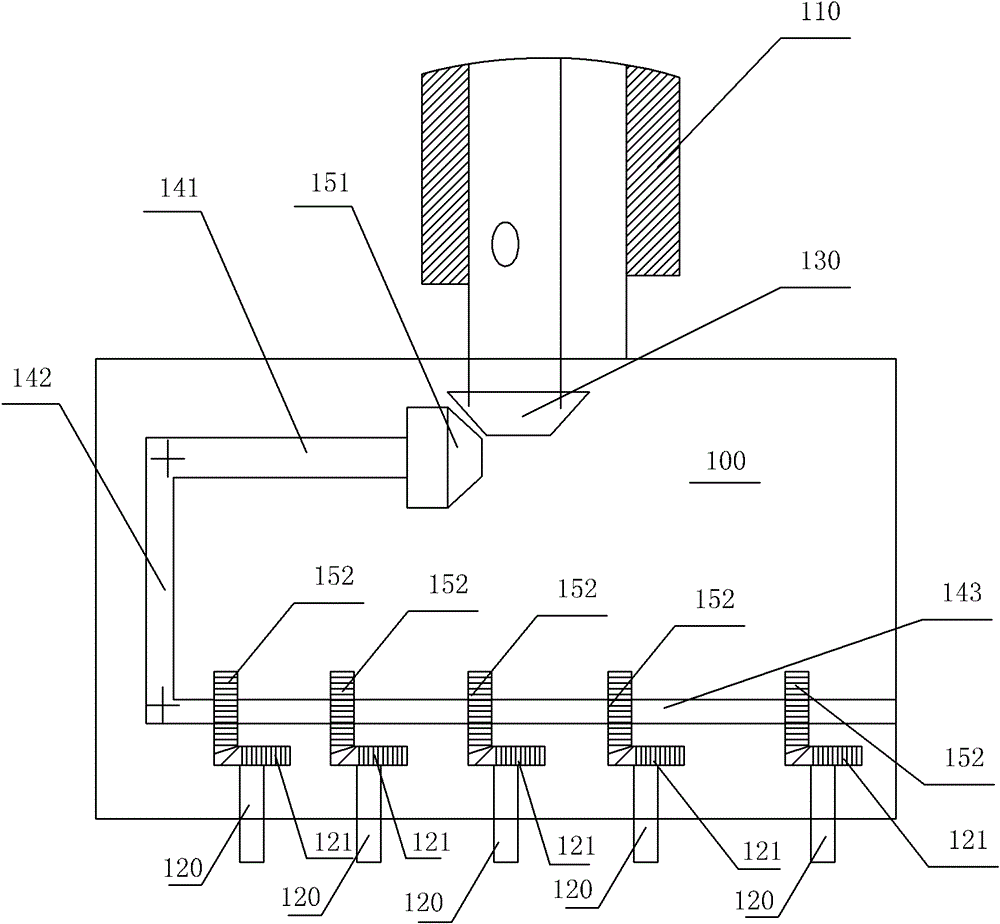

[0028] Refer to attached picture. The present invention includes a drilling device 100 and a cutting tool 200. The drilling device includes a main shaft 110. The drilling device is also provided with a plurality of terminal output shafts 120 in a vertical direction. The terminal output shafts are arranged in a row. Drive their linkage through the transmission device; the group hole drilling system is provided with a plurality of cutters 200, and the plurality of cutters 200 are respectively connected to different terminal output shafts; the cutter is provided with twist drill section 210, expanding Hole knife-shaped section 220, reaming knife-shaped section 230, the twist drill-shaped section 210 is at the front, the reaming knife-shaped section 220 is behind the twist drill-shaped section 210, and the reaming knife-shaped section 230 is in the After the reaming knife section 220. The cutting tool 200 provided by the present invention is a multifunctional compound cutting too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com