Piling process for building sheet pile type wharf in shallow coastal water

A technology of sheet pile wharf and process method, applied in sheet pile walls, water conservancy projects, embankments, etc., can solve the problems of limiting the application range of sheet pile wharf, insufficient water depth, insufficient foundation bearing capacity, etc., and achieve high practical application value and popularization value, reduce the workload, and reduce the effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is achieved through the following technical solutions:

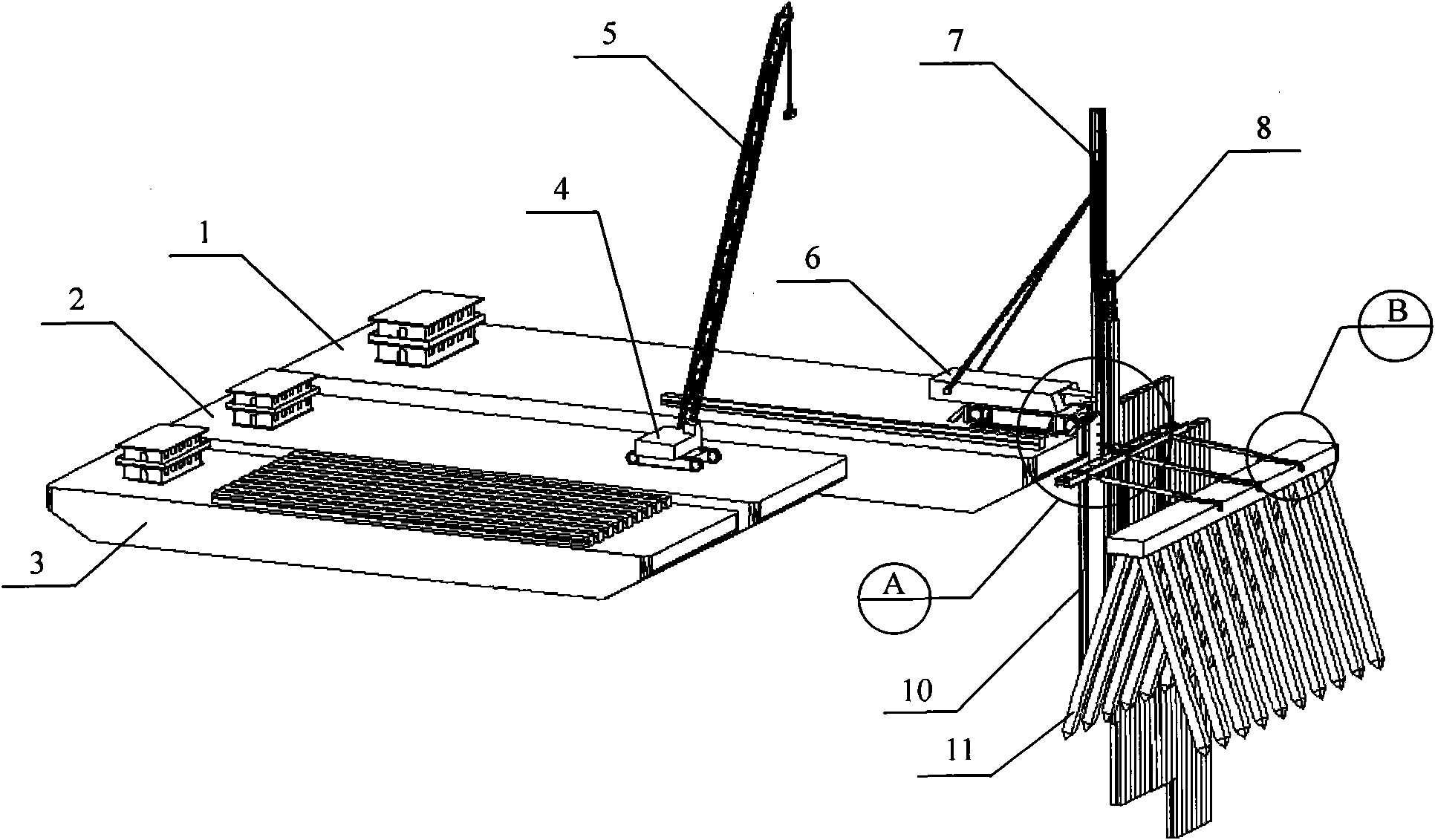

[0024] The invention relates to equipment and auxiliary components for driving sheet piles in shallow water areas, including flat barges, transport barges, land crawler pile drivers, crawler cranes, guide pile guide beams and movable back plates, etc., as attached figure 1 shown.

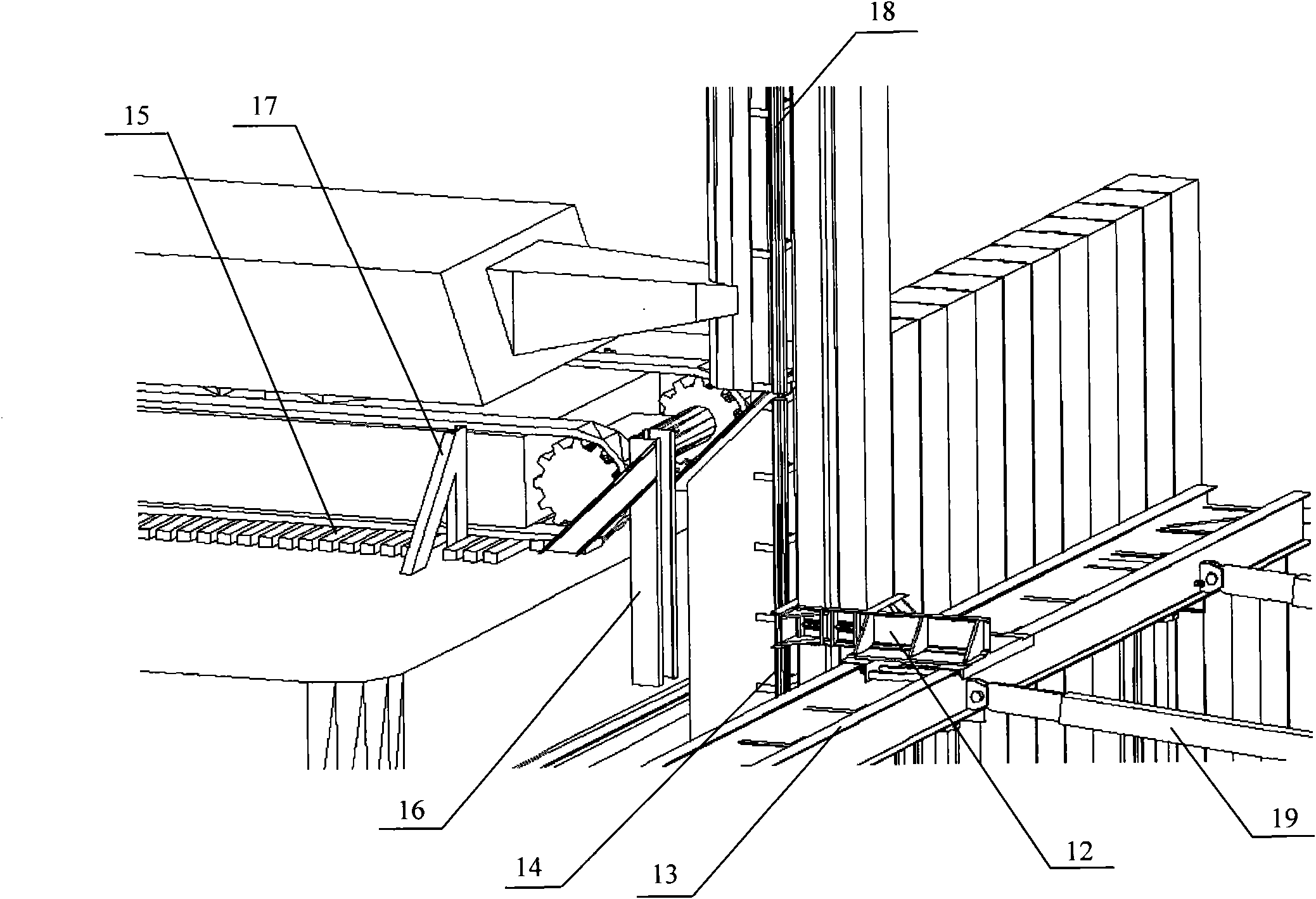

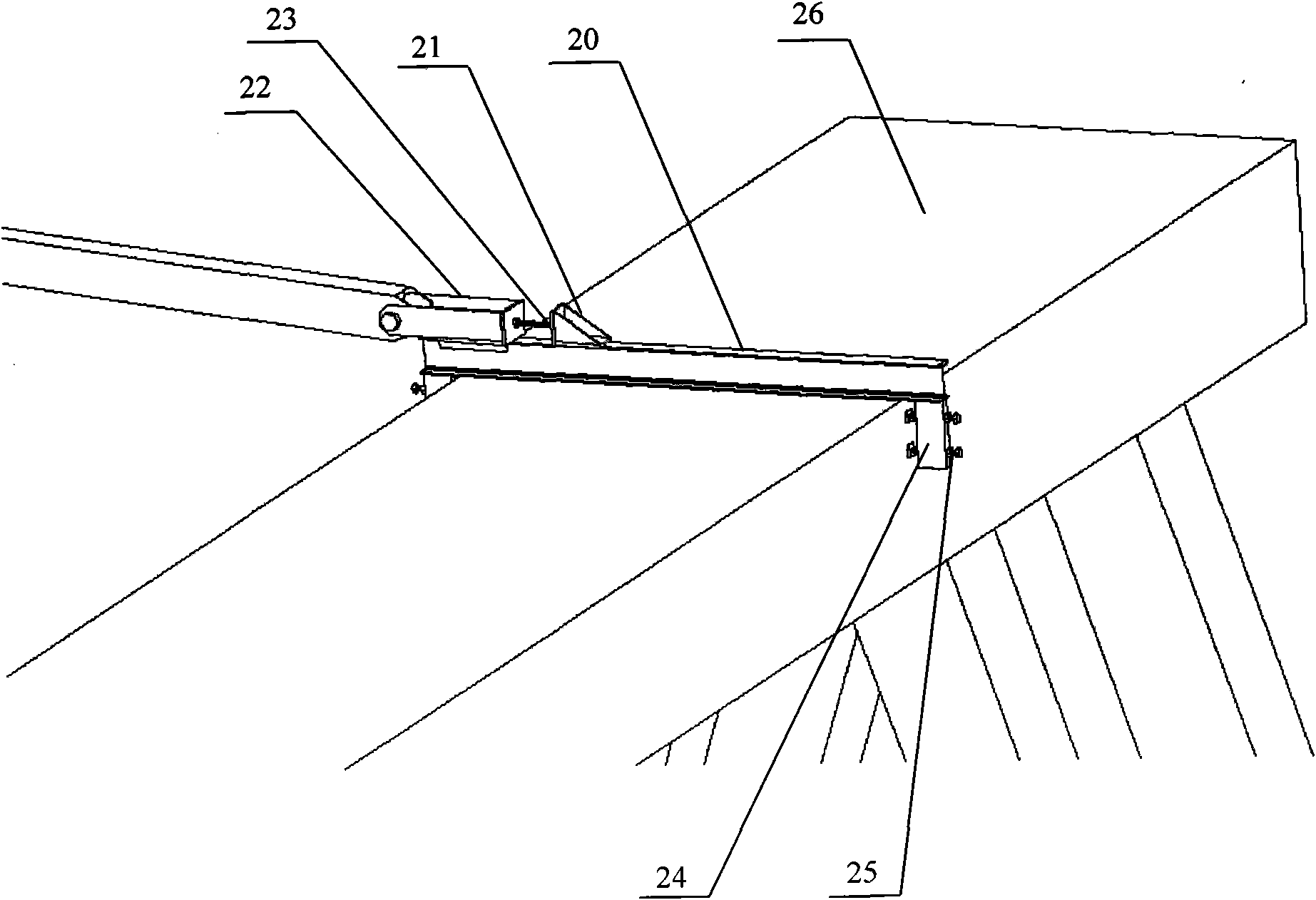

[0025] Explanation of the numbers in the attached drawings: 1 non-self-propelled flat barge, 2 self-propelled flat barge, 3 piling barge, 4 crawler crane, 5, crawler crane pick bar, 6 land crawler pile driver, 7 piling frame, 8 piling hammer, 9 Sheet piles, 10 guide piles, 11 anchor fork piles, 12 movable backboards, 13 guide beams, 14 small dragon mouths, 15 sleepers, 16 front baffles, 17 side baffles, 18 piling frame slides (the bottom is called the dragon mouth ), 19 connecting beam, 20 "U"-shaped fastener beam, 21 connecting beam fixing seat, 22 connecting beam sliding seat, 23 connecting bolt, 24 "U"-shaped f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com