A lower formwork for pipe piles and its hoisting system

A technology of pipe piles and spreaders, applied in the directions of molds, transportation and packaging, load hanging elements, etc., can solve problems such as easy decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

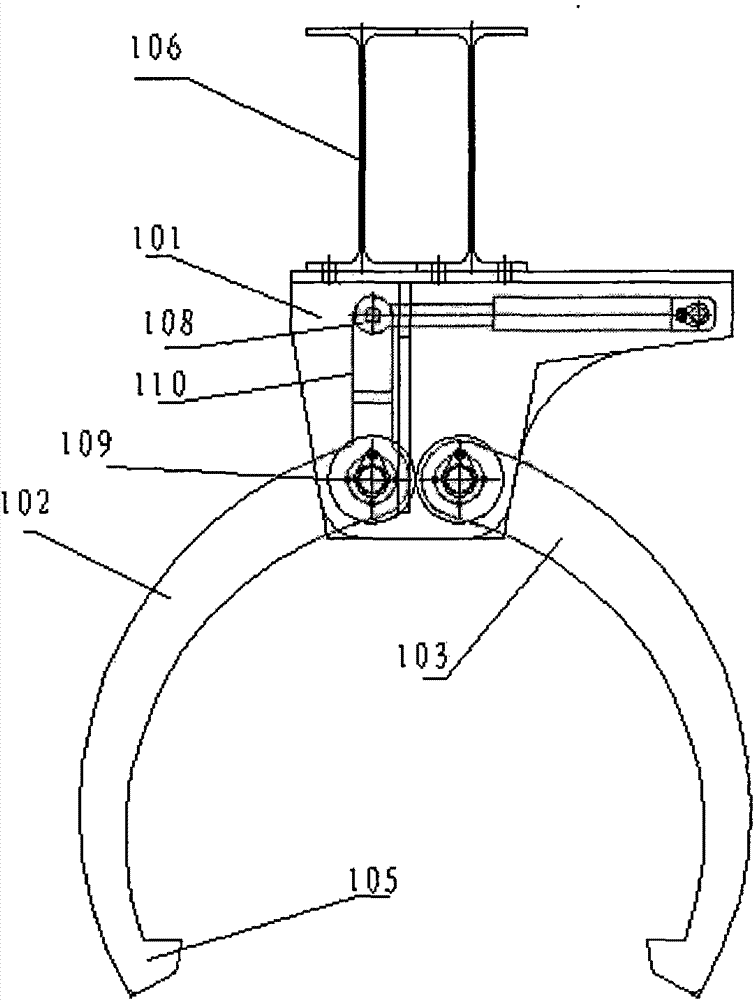

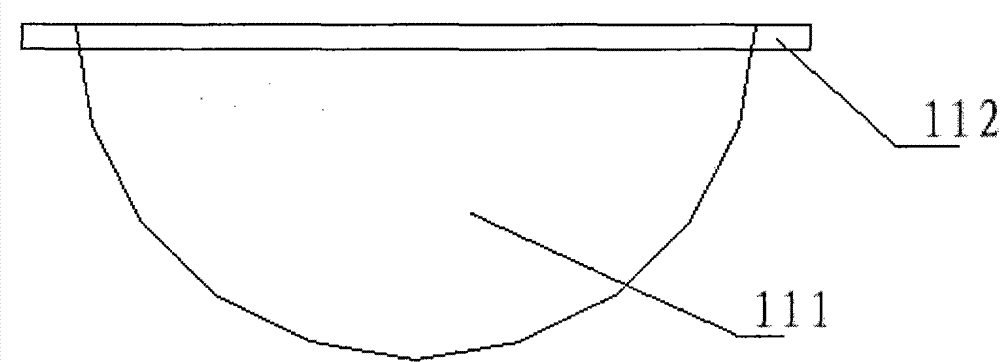

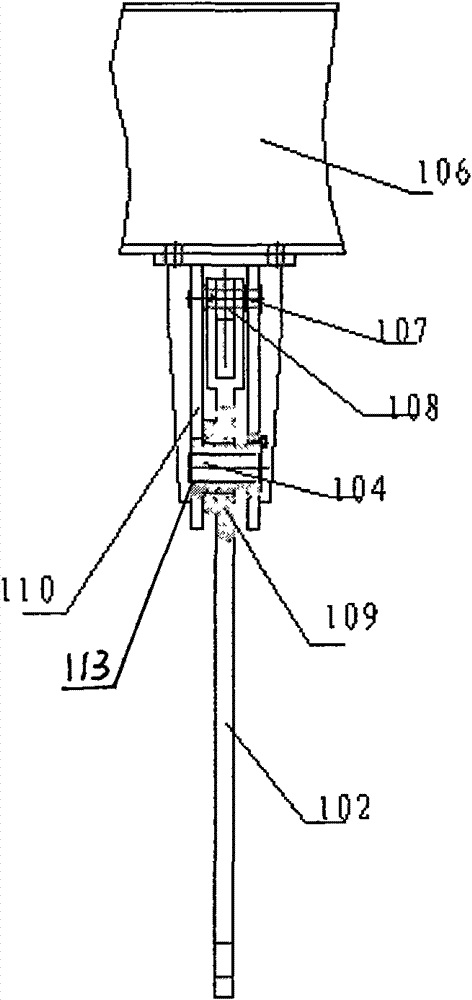

[0017] Embodiment 1, when the staff needs to hoist the lower mold (111) of the pipe pile, the driving vehicle moves to the designated position, the driving control motor works, the motor rotates to drive the upper gear (108) to rotate clockwise, and the middle gear is driven by the chain (110) (113) rotates, middle gear (113) and lower gear (109) coaxially rotate, drives lower gear (109) to rotate, and lower gear (109) rotates the lower gear ( 109) Synchronously rotate in the opposite direction, the lower gears (109) on the left and right sides of the lower end of the bracket (101) rotate, and the left arm (102) and right arm (103) of the spreader connected to it through the pin shaft (104) are opened, and the driving Control and control the hoisting system to descend to the position of the pipe pile lower mold (111), the control system controls the motor to work, the motor rotates to drive the upper gear (108) to rotate counterclockwise, and the chain (110) drives the middle g...

Embodiment 2

[0018] Embodiment 2 After the traffic control hoisting system moves up to the designated position, the traffic control hoisting system descends to the designated position, the traffic control motor works, the motor rotates to drive the upper gear (108) to rotate clockwise, and the chain (110) drives the middle gear (113 ) rotates, the middle gear (113) and the lower gear (109) rotate coaxially, driving the lower gear (109) to rotate, and the rotation of the lower gear (109) drives the lower gear (109) on the right side of the lower end of the bracket (101) engaged with it Synchronously rotate in the opposite direction, the lower gears (109) on the left and right sides of the lower end of the bracket (101) rotate, and the left arm of the spreader (102) and the right arm of the spreader (103) connected to it through the pin shaft (104) are opened, and the pipe pile Lower mold (111) is unloaded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com