Polaroid for ultrathin reflection-type liquid crystal display

A liquid crystal display, reflective technology, applied in the field of polarizers, can solve the problems of thick polarizers and inconvenient use, and achieve the effect of ensuring reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

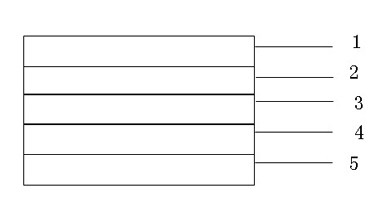

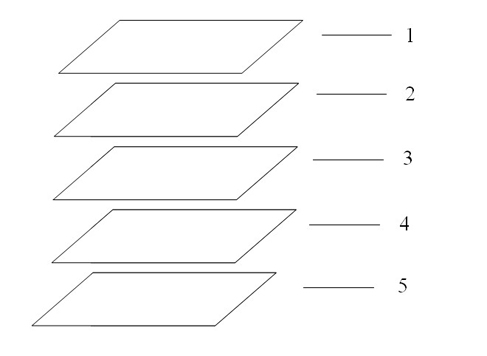

[0017] Such as Figure 1 to Figure 2 As shown, a polarizer for an ultra-thin reflective liquid crystal display, which includes a release film layer 1, a pressure-sensitive adhesive layer 2, a polyvinyl alcohol (PVA) film layer 3, an adhesive layer 4, Reflective film layer 5. The above layers are compounded together by a compound machine.

[0018] The peeling film layer 1 is compounded on the upper surface of the polyvinyl alcohol (PVA) film layer 3 through the above-mentioned pressure-sensitive adhesive layer 2, and the reflective film layer 5 is compounded on the polyvinyl alcohol (PVA) film layer through the above-mentioned adhesive layer 4 The lower surface of layer 3.

[0019] The thickness of the pressure-sensitive adhesive layer 2 and the adhesive layer 4 can be appropriately set according to the intended use, adhesive strength and the like. Specifically, the preferable thickness is 1 μm to 100 μm, more preferably 5 μm to 50 μm, most preferably 10 μm to 30 μm.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com