Superconducting magnet cryogen quench path outlet assembly or method

A cryogen and path technology, applied in the direction of superconducting magnets/coils, container discharge methods, magnetic objects, etc., can solve the problems that refrigerant gas cannot escape, block, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention provides a pre-assembled, pre-tested quench outlet assembly that can be replaced after use and that is not susceptible to clogging by deposits of frozen air components.

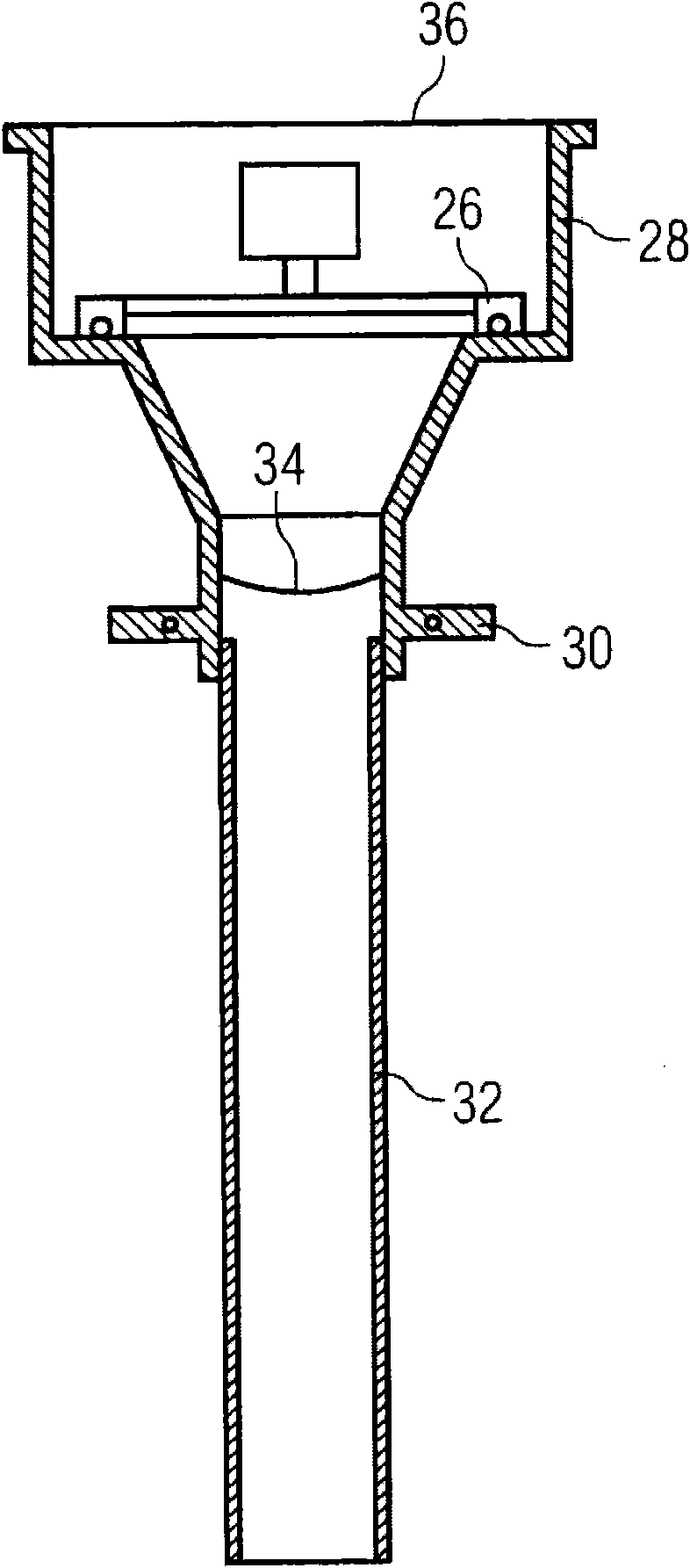

[0047] image 3 A schematic axial section of a quench outlet assembly according to an embodiment of the invention is shown. The part is manufactured and leak tested independently of the cryostat. The quench outlet assembly includes a quench valve 26, as with respect to figure 2 as described. The quench valve 26 itself is seated within a flange 28 which provides a mounting surface 30 and connects to a refrigerant outlet conduit 32 . A burst disc is provided, either upstream of the quench valve, such as at position 34 , or downstream of the quench valve, at position 36 . Burst discs may be provided at both locations 34 and 36 if desired. The cryogen exit conduit 32 is sealed to the flange 28 and burst disk to provide a leak-tight assembly that is leak tested prior to assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com