Embedded air inlet based on vortex excretion and aircraft using embedded air inlet

A technology of embedded air intake and aircraft, which is applied in the field of aircraft, can solve the problems of large outlet flow field distortion and low total pressure recovery coefficient, reduce flow field distortion, improve total pressure recovery coefficient, and have good engineering application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

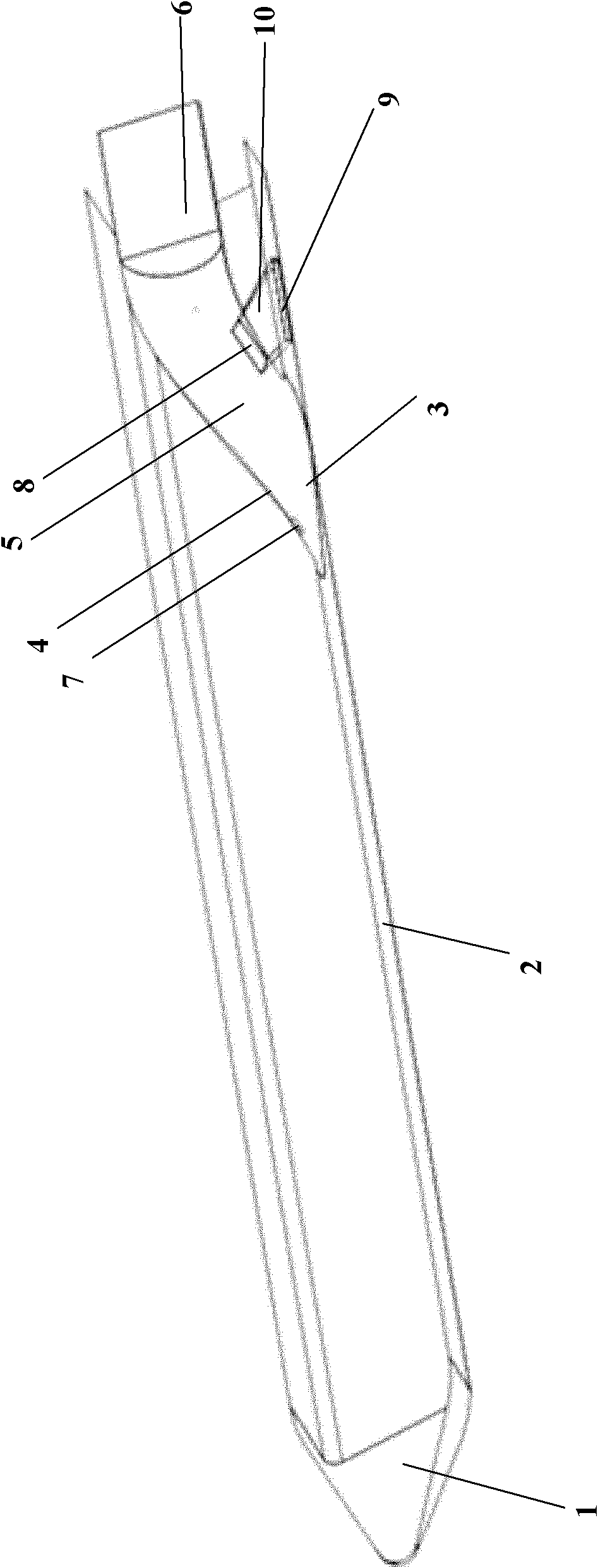

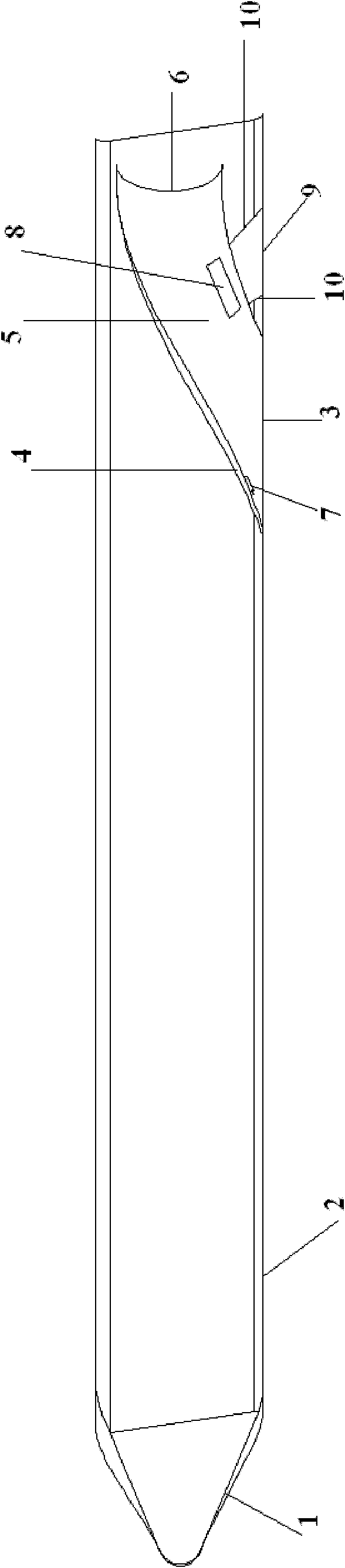

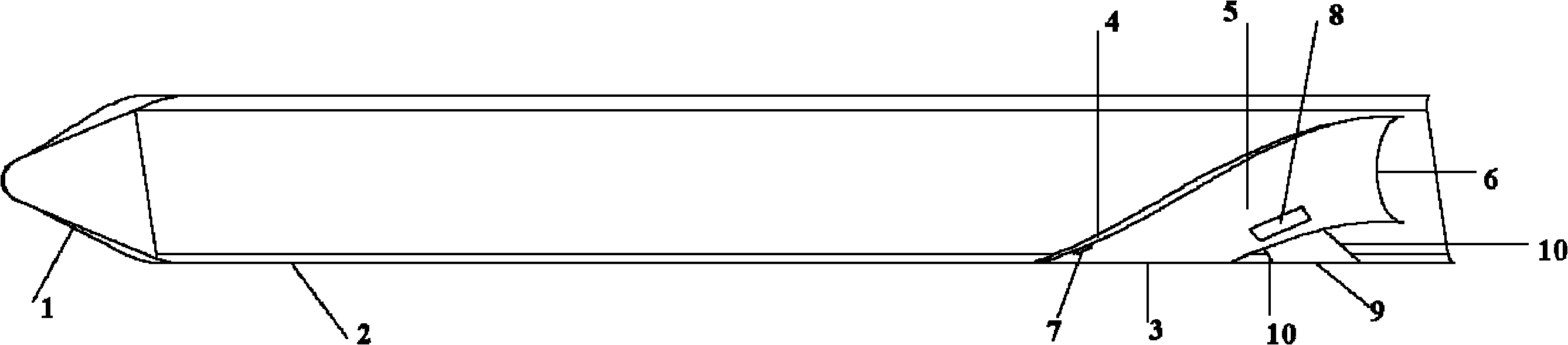

[0015] see figure 1 As shown, the invention discloses a buried air intake based on vortex discharge and an aircraft equipped with the buried air intake.

[0016] The embedded air intake based on vortex drainage has an air intake 3 at the front end, an air outlet 6 at the rear end, and an inner channel 5 connecting the air intake 3 and the air outlet. The inner passage 5 is provided with a front lip guide surface 4 located above the air inlet 3 for guiding airflow, and a spoiler 7 placed on the front lip guide surface 4 . The spoilers 7 can be arranged symmetrically in several rows along the guide surface 4 of the front lip in sequence, and one or two spoilers 7 are placed in each row. The spoiler 7 can sweep part of the low-energy gas flowing in from the front out of the air inlet 3 through both sides of the wall surface of the inner channel 5 . Of course, in other embodiments of the present invention, the spoiler 7 may not be placed.

[0017] The wall surface of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com