Stranding cage disc with molded line stranding and positioning device

A technology of winches and molded wires, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., and can solve the problem that molded wires are prone to misalignment, turning over, unable to meet the requirements of molded wire stranding and armoring, and affecting molded wire stranding Control quality and other issues to achieve the effect of protecting the surface quality and avoiding wire scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

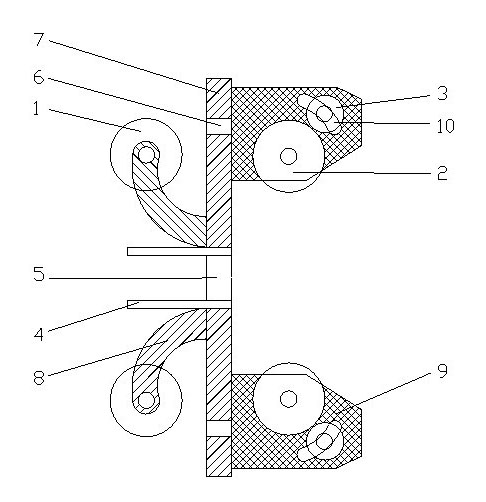

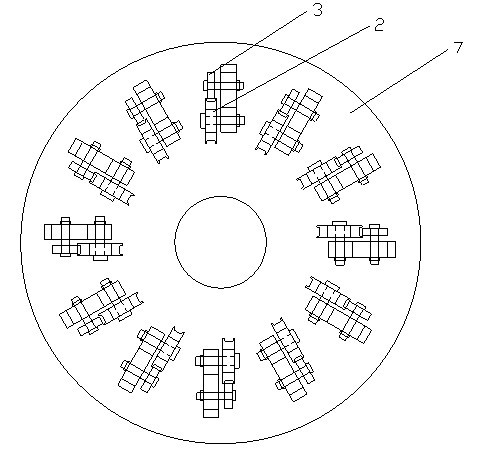

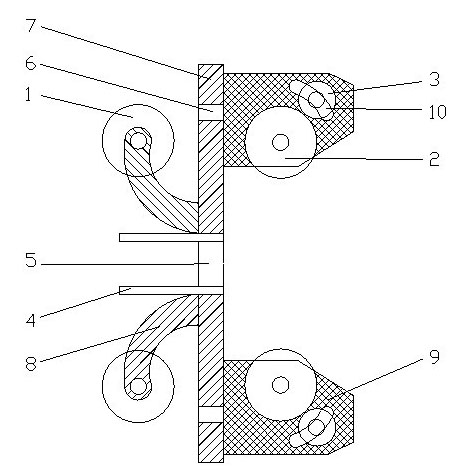

[0013] Such as figure 1 and figure 2 As shown, a winch pan with profiled wire twisting and positioning device of the present invention includes a winch pan body 7, and a center inlet limit tube 4 and a center inlet wire are arranged at the center of the winch pan body 7 The hole 5 is provided in the circumferential direction of the winch pan body 7 as a pair of matching profiled wire inlet base 8 and profiled wire outlet base 9, the number of which is the same as the number of profiled wires, and is concentric around the central wire inlet hole Arranged in equal parts. The molded wire inlet base 8 and the molded wire outlet base 9 are installed on both sides of the winch pan body 7 respectively, and the molded wire inlet hole 6 is provided on the winch pan body 7 between the two bases, and the molded wire inlet The base 8 has an incoming wire guide wheel 1, and an outgoing wire guide wheel 2 and an outgoing wire pinch wheel 3 are arranged on the molding line outlet base 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com