Metal detector for belt conveyer

A technology of metal detectors and belt conveyors, which is applied to instruments, measuring devices, scientific instruments, etc., and can solve problems such as metal detector misoperations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

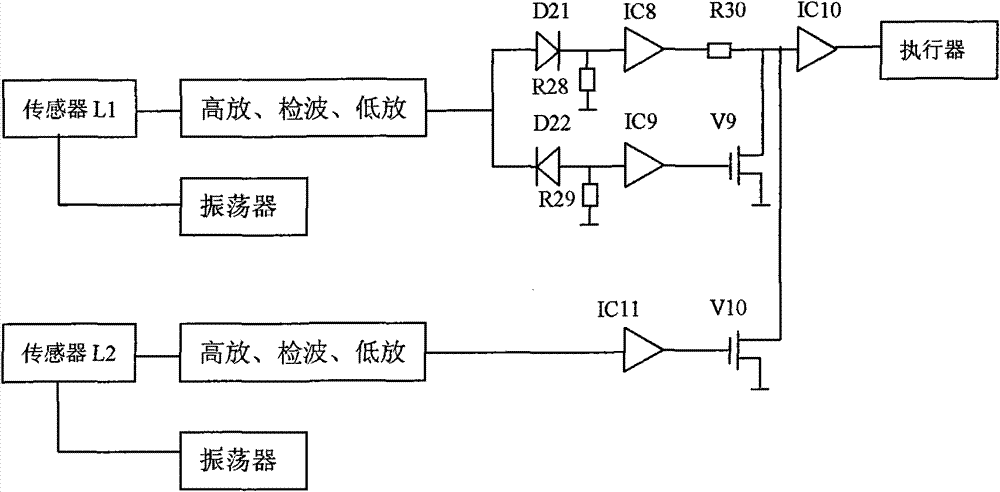

[0012] The present invention has two sensors L1, L2, and sensor L1 is enclosed within on the belt, and sensor L2 is placed on the conveying belt lower side, and sensor L1 and sensor L2 have respective oscillator, high-amplification, wave detection, low-amplification circuits. The output end of the sensor L1 amplifying channel passes through the diodes D21 and D22 to form a positive and negative phase detection circuit, and divides the detected signal into two channels. The channel of the diode D21 (metal reaction channel) is sent to the amplifier IC8, and the output of the amplifier IC8 is sent to the amplifier IC10; The D22 channel (ore reaction channel) is sent to the amplifier IC9, the output of the amplifier IC9 controls the gate of the field effect transistor V9, and the output of the field effect transistor V9 and the resistor R30 divides the voltage to control the input voltage of the amplifier IC10. For ore materials with high magnetic permeability, the eddy current eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com