Tube core of tube bundle dryer with intermediate tubular shaft

A technology of tube bundle drying and intermediate tubes, which is applied in the direction of dryers, drying, heating devices, etc., and can solve problems such as fracture, low rigidity, and affecting the performance and life of the dryer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

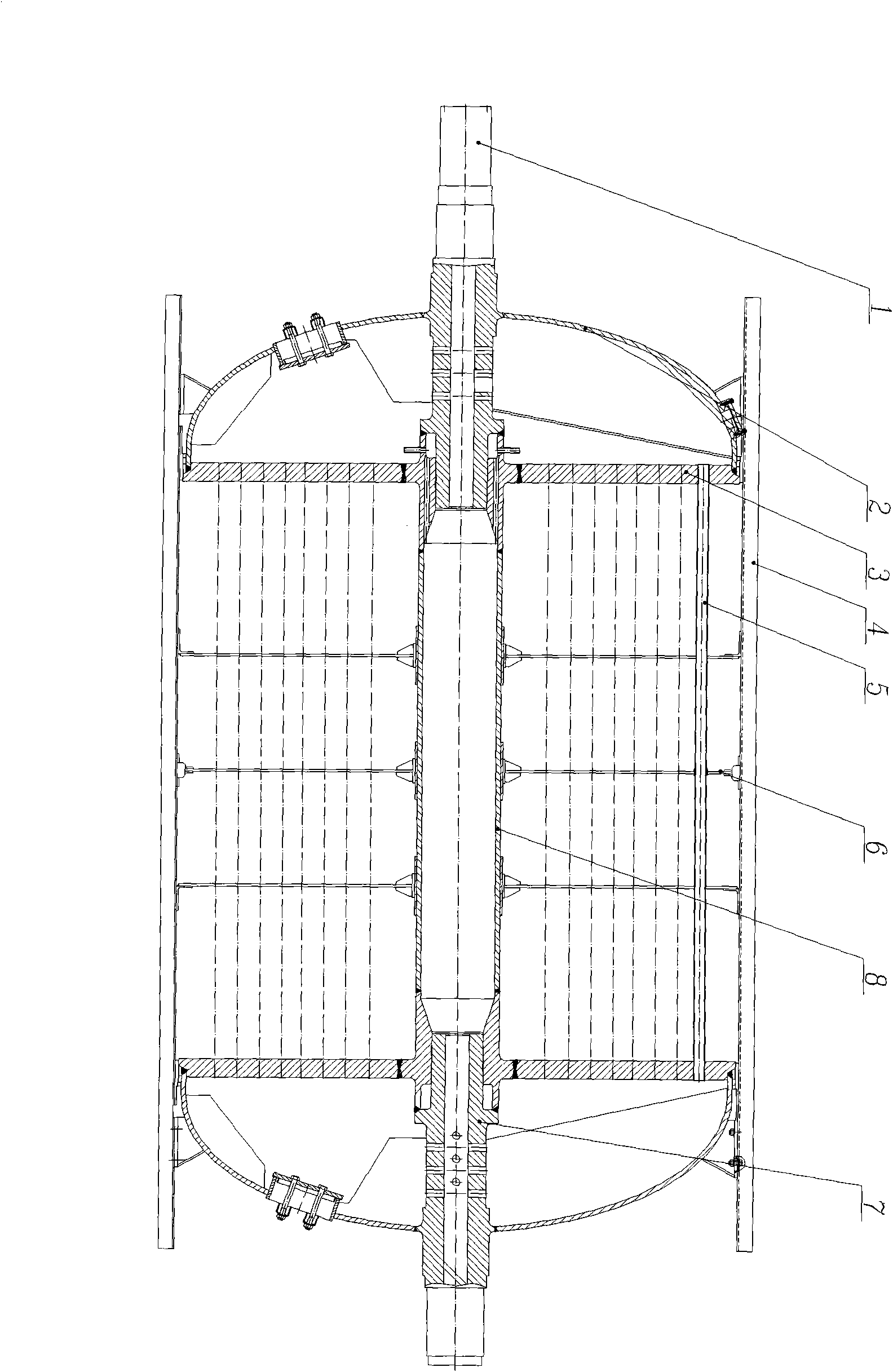

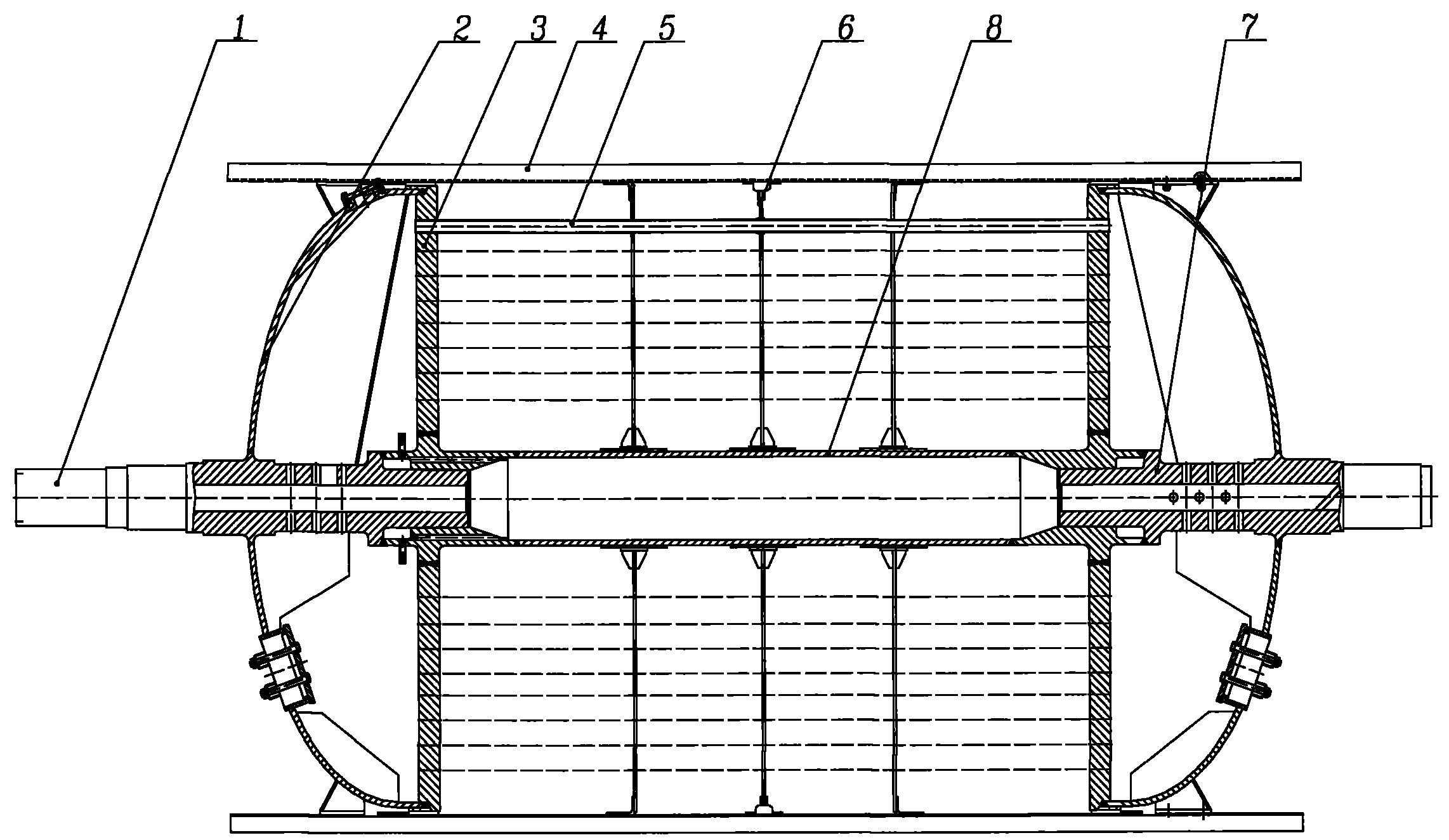

[0006] Tube bundle dryer tube core with intermediate tube shaft, including head 2, tube plate 3, support plate 6, solid shovel angle steel 4, heat exchange tube 5, steam inlet shaft 7, steam outlet shaft 1, steam inlet shaft 7, outlet The steam shaft 1 is respectively welded on the end caps 2 at both ends and communicates with the heat exchange tube 5 through the tube plate 3. A central tube shaft 8 passes through the support plate 6, and its two ends are respectively welded on the tube plate 3. The steam inlet shaft 7 1. The shaft head of the steam outlet shaft 1 is respectively inserted into the central tube shaft 8 and welded into one body with the central tube shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com