Glue solution for surface treatment of nickel-metal hydride (NI-MH) battery plate and gum dipping device

A battery plate and nickel metal hydride battery technology, applied in the direction of alkaline storage battery electrodes, etc., can solve the problems of hard plate and easy powder drop of the plate, and achieve the effect of reducing floating powder and improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the preparation steps of glue solution are as follows:

[0017] 1. Mix PTFE emulsion with a mass concentration of 60% and pure water to prepare a PTFE solution with a mass ratio of 5%;

[0018] 2. Slowly add CMC or HPMC to pure water at 60°C to prepare a 1% CMC or HPMC solution by mass;

[0019] 3. Mix PTFE solution, CMC or HPMC solution and SBR glue in proportion to prepare the glue used for plate dipping. The mass ratios of PTFE, SBR, CMC or HPMC in the glue are: 4%, 0.5% %, 0.4%.

Embodiment 2

[0020] Embodiment 2: the preparation steps of glue solution are as follows:

[0021] 1. Mix PTFE emulsion with a mass concentration of 60% and pure water to prepare a PTFE solution with a mass ratio of 12.5%;

[0022] 2. Slowly add CMC or HPMC into pure water at 60°C to prepare a 3% CMC or HPMC solution by mass;

[0023] 3. Mix PTFE solution, CMC or HPMC solution and SBR glue in proportion to prepare the glue used for plate dipping. The mass ratios of PTFE, SBR, CMC or HPMC in the glue are: 10%, 1.25% %, 1.2%.

Embodiment 3

[0024] Embodiment 3: the preparation steps of glue solution are as follows:

[0025] 1. Mix PTFE emulsion with a mass concentration of 60% and pure water to prepare a PTFE solution with a mass ratio of 20%;

[0026] 2. Slowly add CMC or HPMC to pure water at 60°C to prepare a 5% CMC or HPMC solution by mass;

[0027] 3. Mix PTFE solution, CMC or HPMC solution and SBR glue in proportion to prepare the glue used for plate dipping. The mass ratios of PTFE, SBR, CMC or HPMC in the glue are: 16%, 2 %,2%.

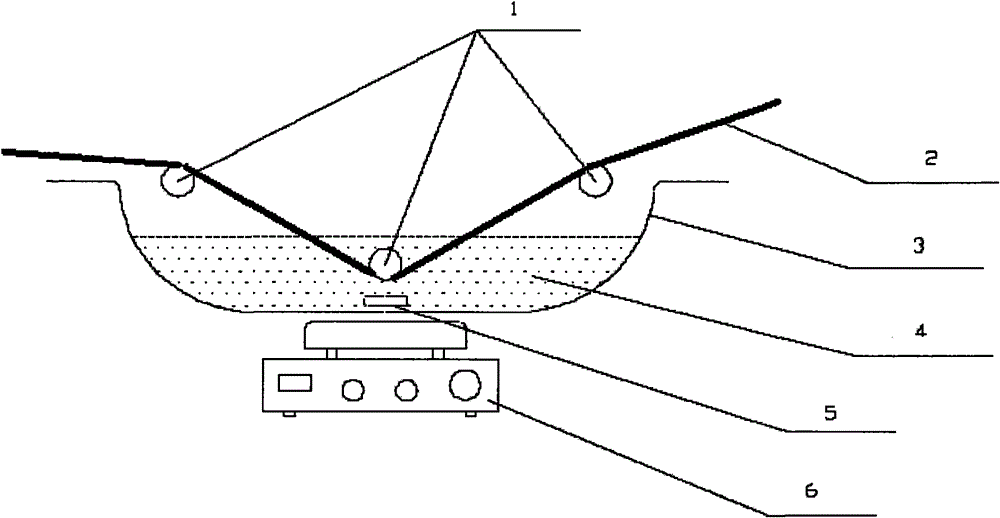

[0028] Such as figure 1 As shown, the dipping device includes a dipping tank 3, a fixed shaft 1 and a magnetic stirrer 6, the magnetic stirrer 6 is installed below the dipping tank 3, and the rotor 5 of the magnetic stirrer 6 is installed at the bottom of the dipping tank 3, a set The fixed shaft 1 of the battery pole plate is installed in the dipping tank 3 .

[0029] When working, put the glue solution 4 in the dipping tank 3, and the pole plate is installed on the fixed sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com