Method for improving precision of infrared touch screen

An infrared touch screen and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problem of inaccurate coordinate values and achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings in conjunction with the embodiments, so that those skilled in the art can better understand the present invention and implement it, but the given embodiments are not intended to limit the present invention.

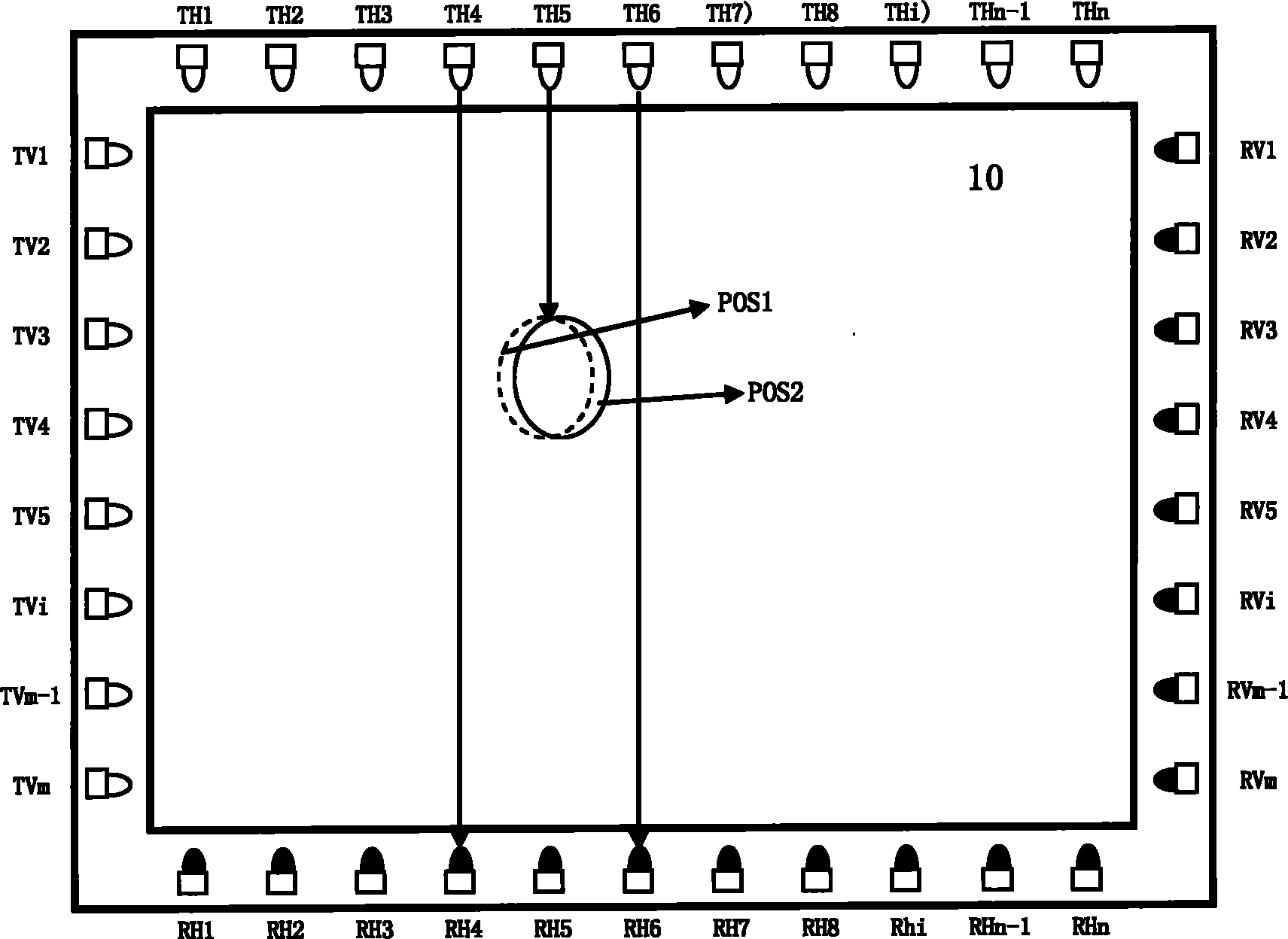

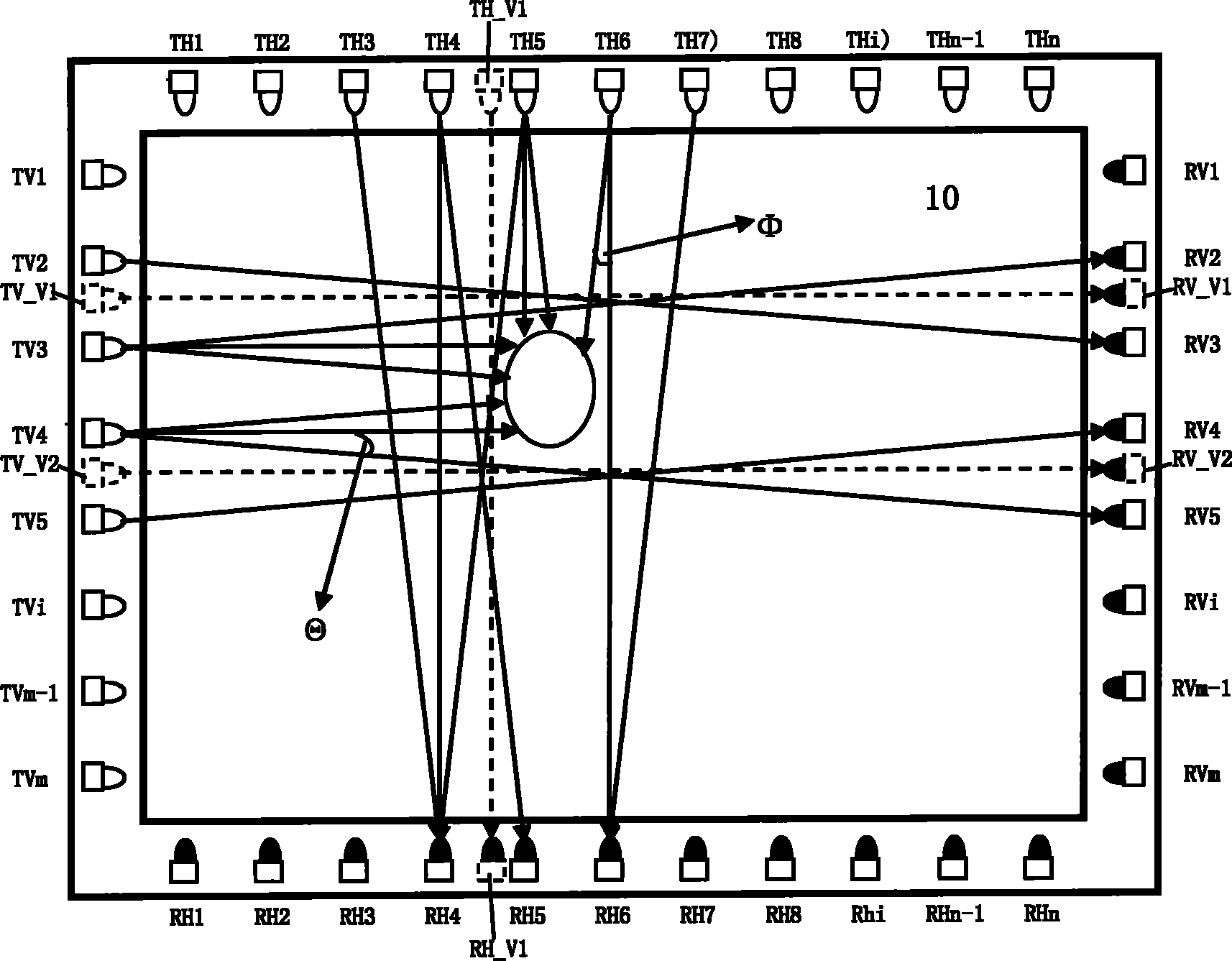

[0017] Such as figure 2 , for each receiving light, scanning can realize three transmitting lights within the range, for the receiving light RHi, turn on the transmitting lights THi-1, THi, THi+1 in sequence, and for the receiving light RVi, turn on the transmitting lights TVi-1, TVi in turn , TVi+1, so that each receiving light corresponds to three transmitting lights.

[0018] When initially powered on, ensure that the touch screen is not blocked, scan for a week, and record the scanning value of each receiving light corresponding to the transmitting light: AD_INI_RH1_TH1, AD_INI_RH1_TH2, AD_INI_RH2_TH1, AD_INI_RH2_TH2, AD_INI_RH2_TH3... ..........AD_INI_RHn-1_THn,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com