Digital holographic high-precision foil-feeding device of bronzing machine

A technology of digital holography and hot stamping machine, applied in printing machine, gold powder printing, rotary printing machine and other directions, can solve the problems of inconsistent foil speed, reduced hot stamping accuracy, and inability to adjust the anodized aluminum coil individually, and achieves the structure Simple, improved hot stamping accuracy, high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

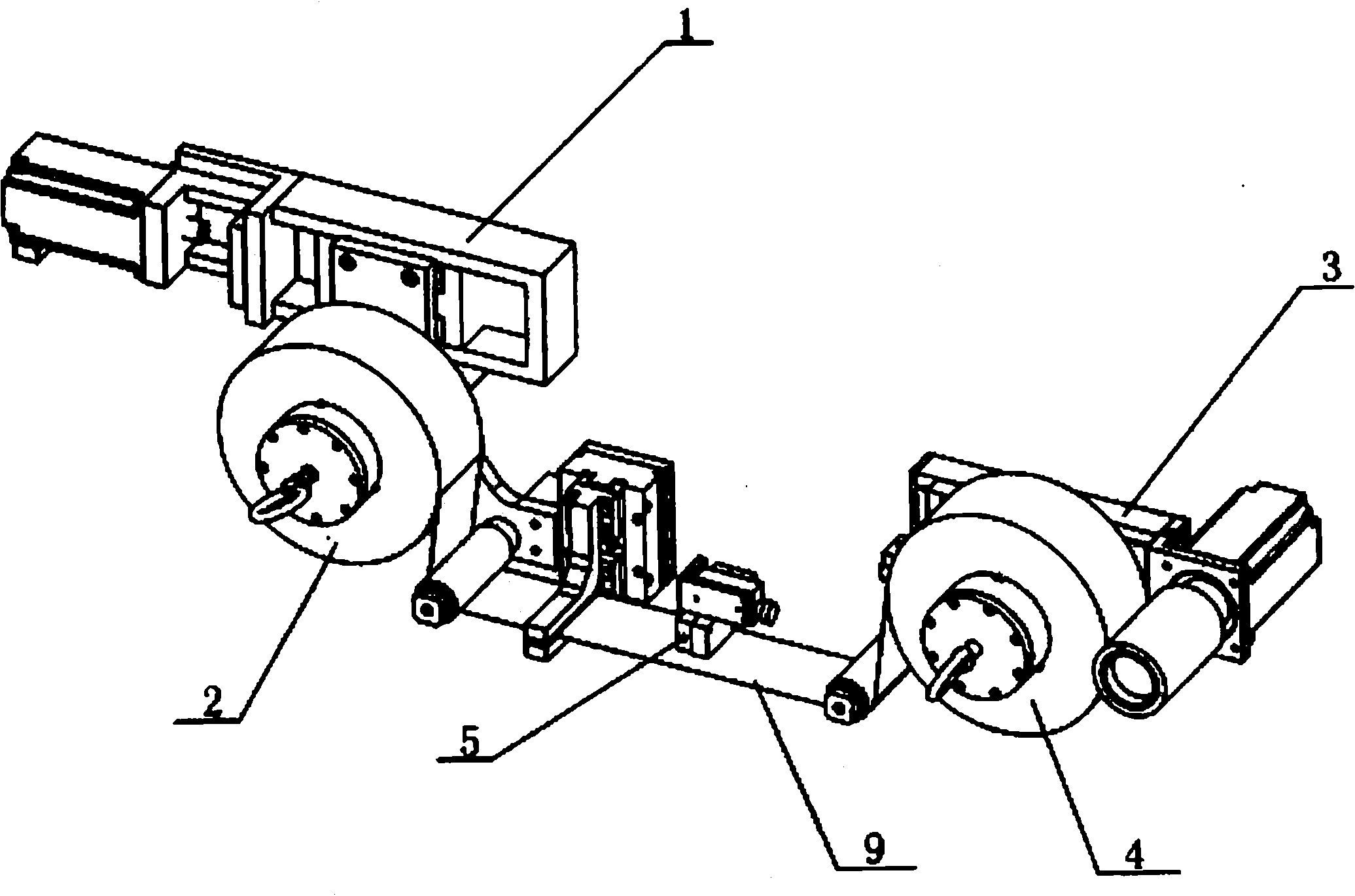

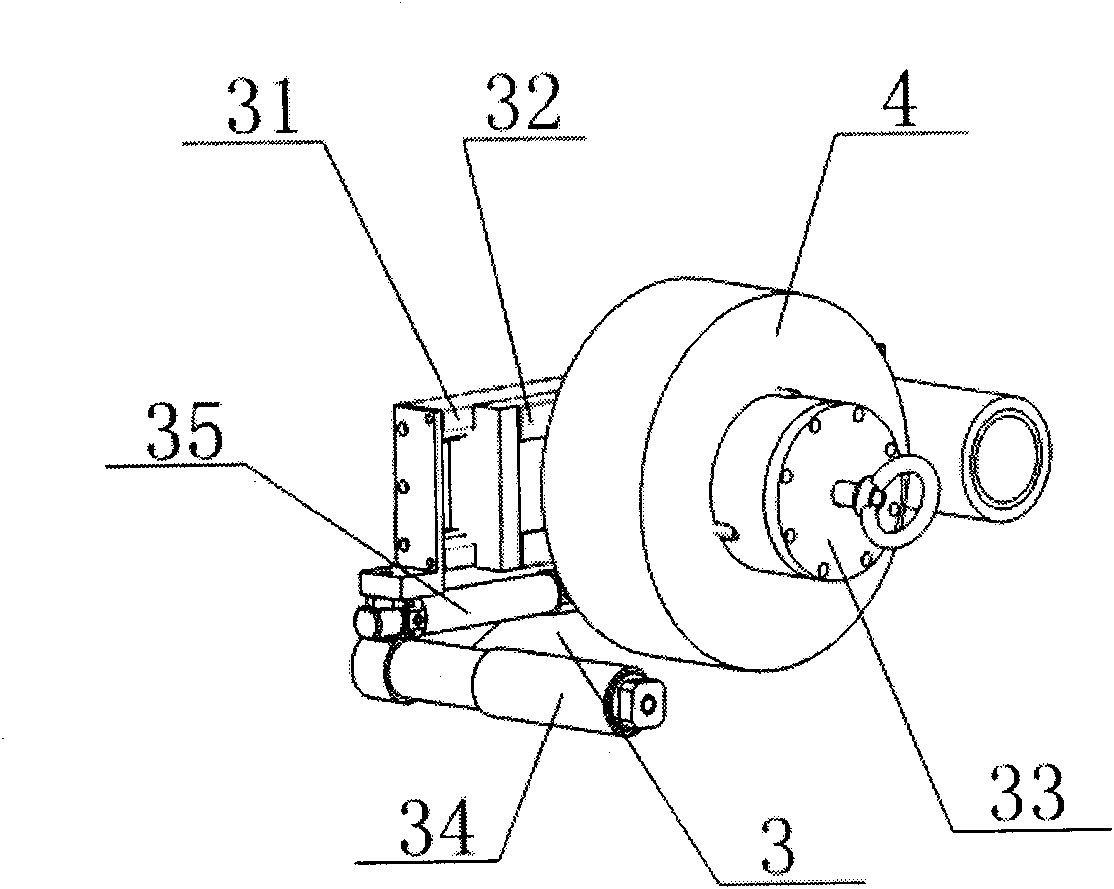

[0018] See Figure 1 to Figure 4 As shown, the present invention is a digital holographic high-precision foil walking device for a hot stamping machine, which includes a foil placing device 1, a foil collecting device 3, a color mark sensor 5 and other components.

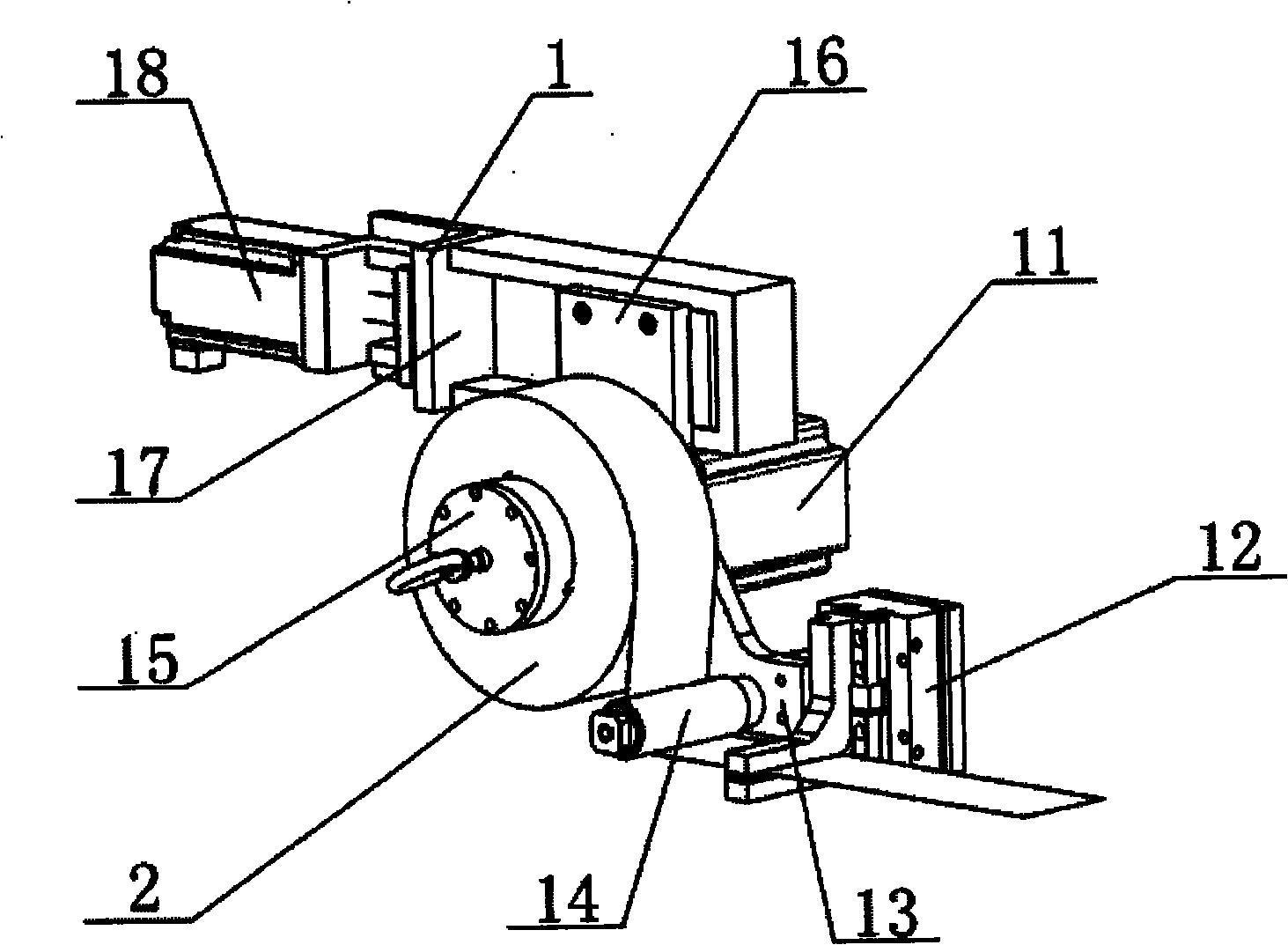

[0019] Wherein, the foil discharge device 1 includes a first servo motor 11, an anodized aluminum pressure nozzle 12, a foil discharge support plate 13, a first positioning guide shaft 14, a tension shaft 15, a linear module slider 16, and a linear module guide rail 17 and the linear module servo motor 18. Further, the linear module slider 16 cooperates with the linear module guide rail 17, which can be linearly moved along the linear module guide rail 17 under the drive of the linear module servo motor 18, and is driven by the first servo motor 11, electrochemical The aluminum pressure nozzle 12, the foil placing support plate 13, the first positioning guide shaft 14, and the tension shaft 15 complete the foil feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com