Bioreactor

A bioreactor and container technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problem of low gas-liquid-solid separation efficiency, improve biological treatment reaction efficiency, prevent gas Flow into the discharge pipe and the effect of improving the efficiency of gas-liquid-solid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments will be described with reference to the drawings.

[0045] [Bioreactor in which the solid component discharge pipe is inclined as a whole]

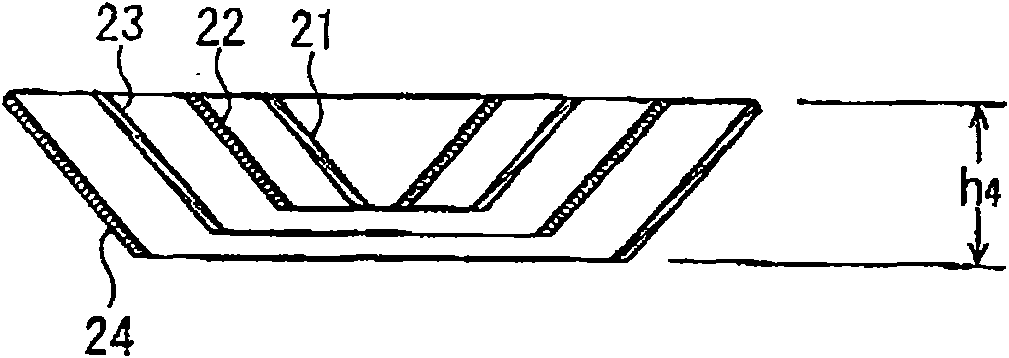

[0046] figure 1 It is a longitudinal sectional view of a bioreactor in which the solid component discharge pipe is inclined as a whole, figure 2 (a) is figure 1 The enlarged view of the upper part of the bioreactor in figure 2 (b) is a plan view of the gas-liquid-solid separator, image 3 It is the longitudinal section view of the baffle. also, figure 2 (a) display edge figure 2 (b) A-A line section. Figure 4 (a) is an enlarged view of the upper part of the bioreactor of another embodiment, Figure 4 (b) is Figure 4 (a) Perspective view of the gas-liquid-solid separator in (a).

[0047] Figure 1 to Figure 3 In the shown embodiment, the container 1 is cylindrical, and raw water (raw water) is supplied from the raw water pipeline 2 to the distributor (distributor) 3 in the lower part of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com