Bioreactor

A bioreactor and container technology, which is applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low gas-liquid-solid separation efficiency, etc. The effect of improving the solid separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, embodiments will be described with reference to the drawings.

[0044] [Bioreactor in which the solid component discharge pipe is inclined as a whole]

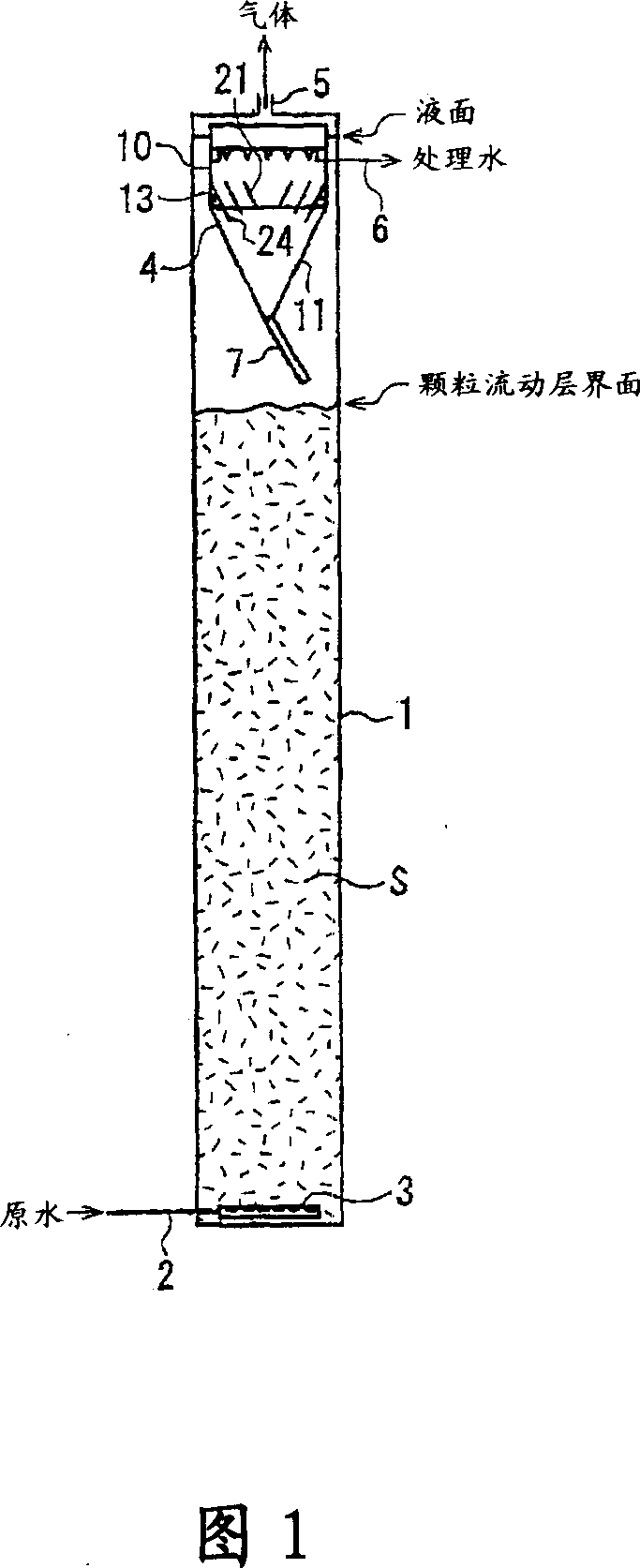

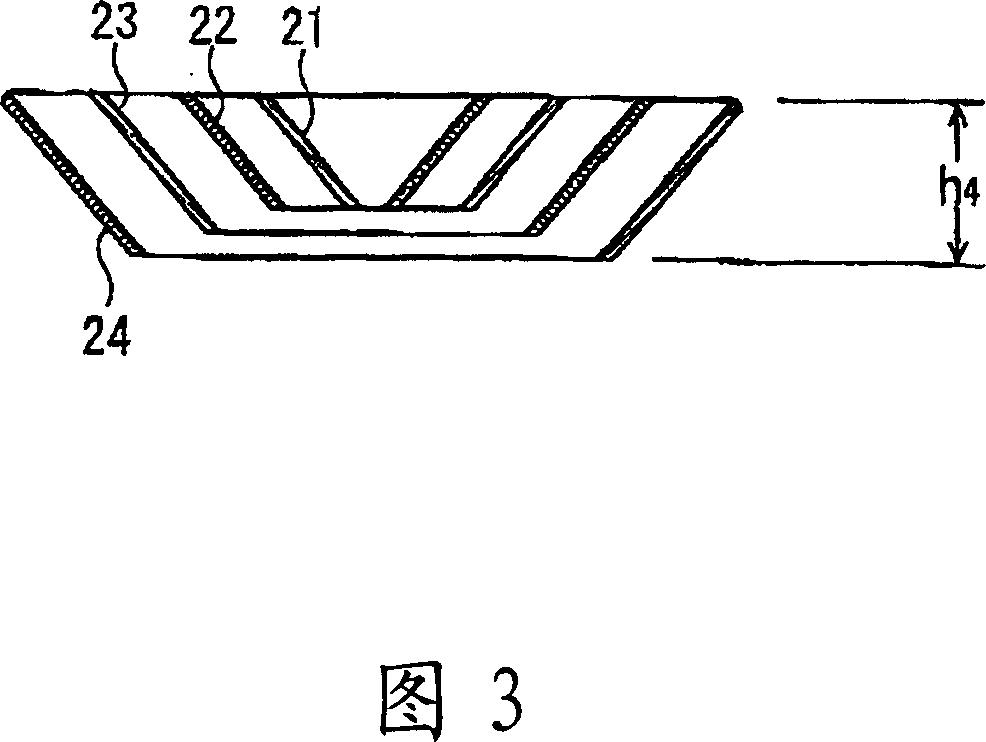

[0045] Fig. 1 is the longitudinal sectional view of the bioreactor of the whole inclined embodiment of the solid component discharge pipe, Fig. 2 (a) is the top enlarged view of the bioreactor in Fig. 1, Fig. 2 (b) is the plane view of the gas-liquid-solid separator , Figure 3 is a longitudinal sectional view of the baffle. In addition, FIG. 2( a ) shows a cross section along line A-A of FIG. 2( b ). Fig. 4(a) is an enlarged view of the upper part of the bioreactor in another embodiment, and Fig. 4(b) is a perspective view of the gas-liquid-solid separator in Fig. 4(a).

[0046]In the embodiment shown in Fig. 1 to Fig. 3, the container 1 is cylindrical, and the raw water (raw water) is supplied from the raw water pipeline 2 to the distributor (distributor) 3 in the lower part of the container 1, and is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com